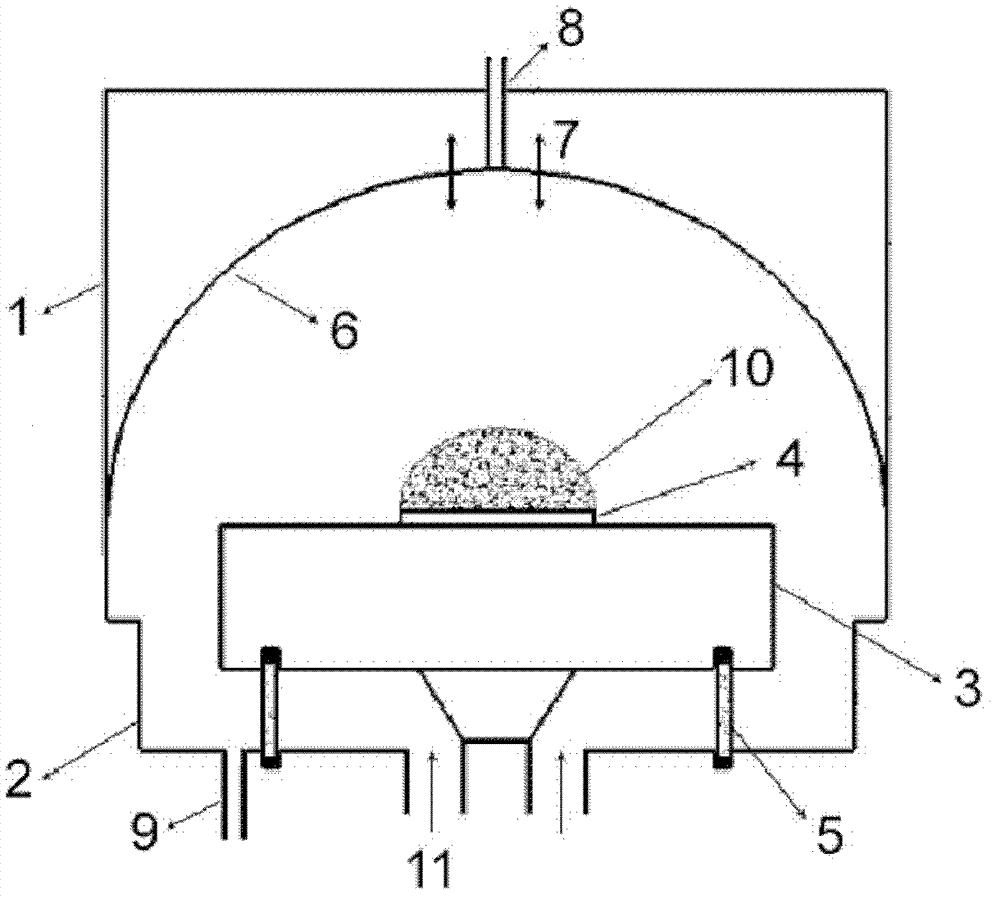

High power microwave plasma chemical vapor deposition device for diamond film

A microwave plasma and diamond film technology, which is applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem that the distance from the plasma device is difficult to adjust and increase the microwave power, and achieve the ability to focus the strong microwave electric field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using the MPCVD diamond film deposition device proposed by the present invention, the device is pre-evacuated to below 1Pa using a vacuum pump, and then H 2 and CH 4 Feed gas consisting of two gases, H 2 The flow rate is 600 ml / min, CH 4 The flow rate is 10 ml / min. After the gas pressure in the device reaches 1kPa, microwaves with a frequency of 2.45GHz and a power of 1kW are input to excite plasma in the device. At this time, use the adjustment mechanism provided by the device to adjust the semi-ellipsoidal microwave reflector, so that the plasma can reach the best distribution state above the deposition table and the diamond film deposition substrate. Thereafter, the gas pressure and microwave power were adjusted to 18kPa and 10kW, respectively, and the deposition of the diamond film was started. After 48 hours of deposition, the microwave power supply, gas and vacuum pumps were turned off in order to end the deposition process of the diamond film. Thus, a diamon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com