A method and device for preparing a uniform and high-density nanoparticle film

A nano-particle and high-density technology, applied in the direction of nanotechnology, can solve the problems that millimeter-scale products cannot be obtained, and the density of thin films needs to be improved, so as to achieve the effect of controllable uniformity and controllable deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

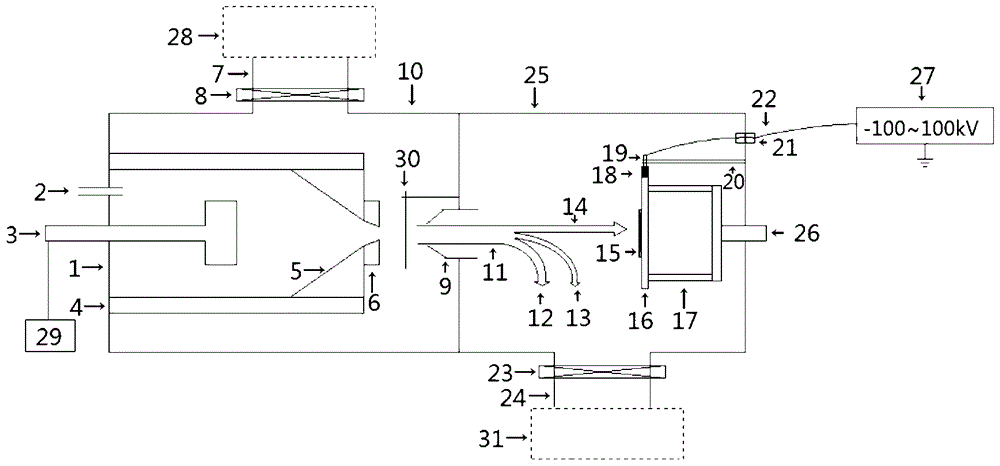

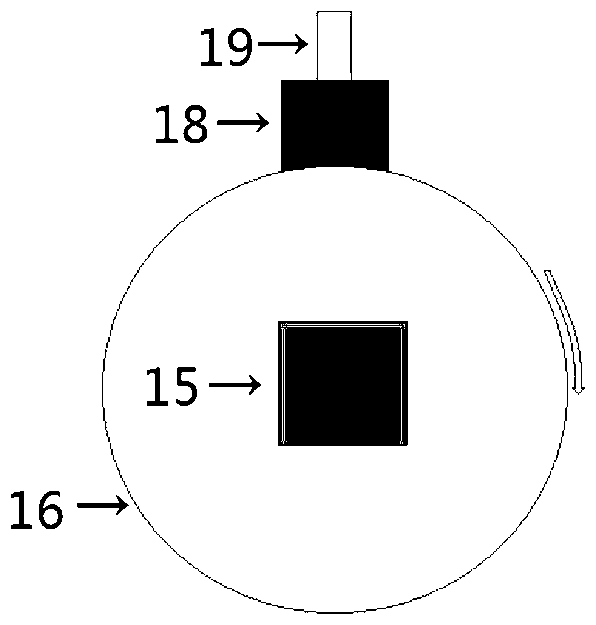

[0064] The principle of the preparation method and device of the uniform and high-density thin film of the present invention is to apply a voltage on the substrate to attract particles in the plasma nanoparticle beam generated by the gas-phase cluster beam source that are opposite to the electric field applied , so that it accelerates and hits the substrate to promote the dense accumulation of deposited particles; the sample stage is rotated by the motor drive, and the particles are deposited on the surface of the substrate uniformly at high speed to form a uniform and high-density film.

[0065] The preparation device of the uniform and high-density film of the present invention mainly includes a sputtering target gun 3, a substrate 15, a sample stage 16, a sputtering chamber 1, a transition chamber 10, a deposition chamber 25, a high voltage system 27, a cooling system, transition chamber vacuum system 28, deposition chamber vacuum system 31 and rotation system 26.

[0066] ...

Embodiment 1

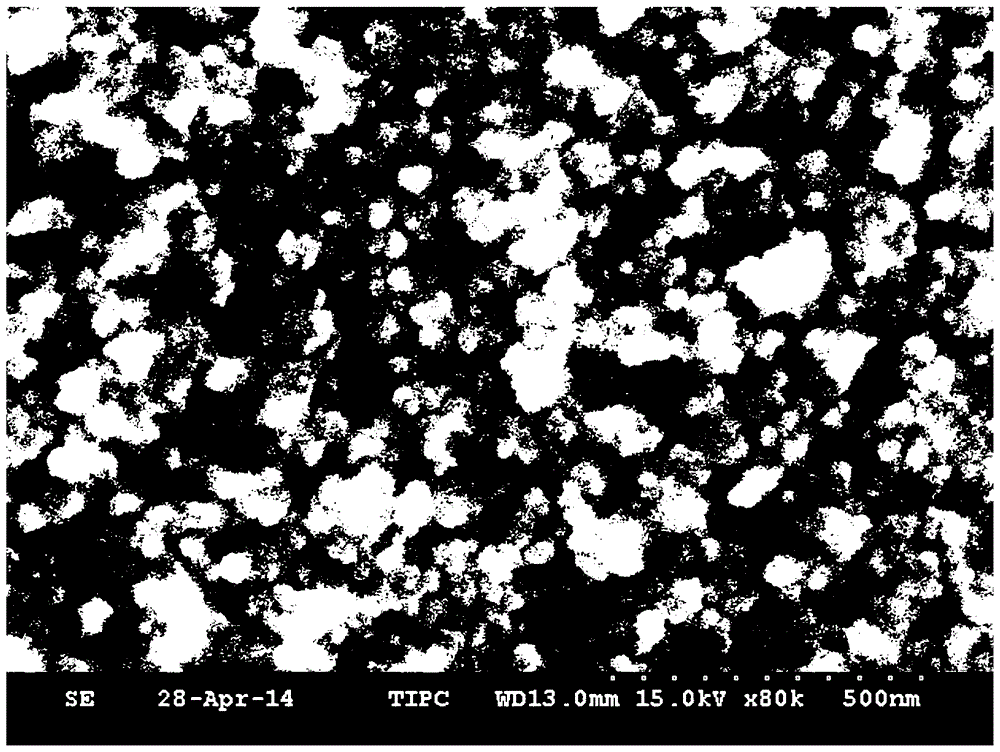

[0083] The preparation method of the uniform, highly dense film of embodiment 1 may further comprise the steps:

[0084] 1) The polysilicon substrate 15 is ultrasonically cleaned with acetone, absolute ethanol, and deionized water, blown dry with a nitrogen gun, and then placed in an oven for drying. The cleaned substrate 15 is mounted on the sample stage 16, and simultaneously The target material (Fe 50 Ni 50 target);

[0085] 2) Turn on the transition chamber vacuum system 28 and the deposition chamber vacuum system 31 until the sputtering background vacuum in the deposition chamber 25 is higher than 5×10 -4 Pa;

[0086] 3) Turn on the cooling system of the sputtering chamber 1 and adjust the temperature of the cooling liquid 4 to 10°C;

[0087] 4) Pass into the Ar gas of 120 sccm in the sputtering chamber 1 through the inlet pipe 2;

[0088] 5) Adjust the transition chamber plate valve 8 so that the air pressure in the sputtering chamber 1 is 90Pa, the air pressure in ...

Embodiment 2

[0096] The preparation method of the uniform, highly dense film of embodiment 2, comprises the following steps:

[0097] 1) The polysilicon substrate is ultrasonically cleaned with acetone, absolute ethanol, and deionized water, blown dry with a nitrogen gun, and then placed in an oven for drying. Install the target material (Fe 50 Ni 50 target);

[0098] 2) Turn on the transition chamber vacuum system 28 and the deposition chamber vacuum system 31 until the sputtering background vacuum in the deposition chamber 25 is higher than 5×10 -4 Pa;

[0099] 3) Turn on the cooling system of the sputtering chamber 1 and adjust the temperature of the cooling liquid 4 to 10°C;

[0100] 4) Pass into the Ar gas of 120 sccm in the sputtering chamber 1 through the inlet pipe 2;

[0101] 5) Adjust the transition chamber plate valve 8 so that the air pressure in the sputtering chamber is 90Pa, the air pressure in the transition chamber is 2Pa, the air pressure in the deposition chamber is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com