Method for processing soft soil foundation with environment-friendly light pile

A lightweight material, soft soil foundation technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of low strength, easy damage to the original ecological environment of buildings, poor water permeability, etc., and achieve the durability of pile foundation quality. Long, strong adaptability of construction technology, low cost of materials and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

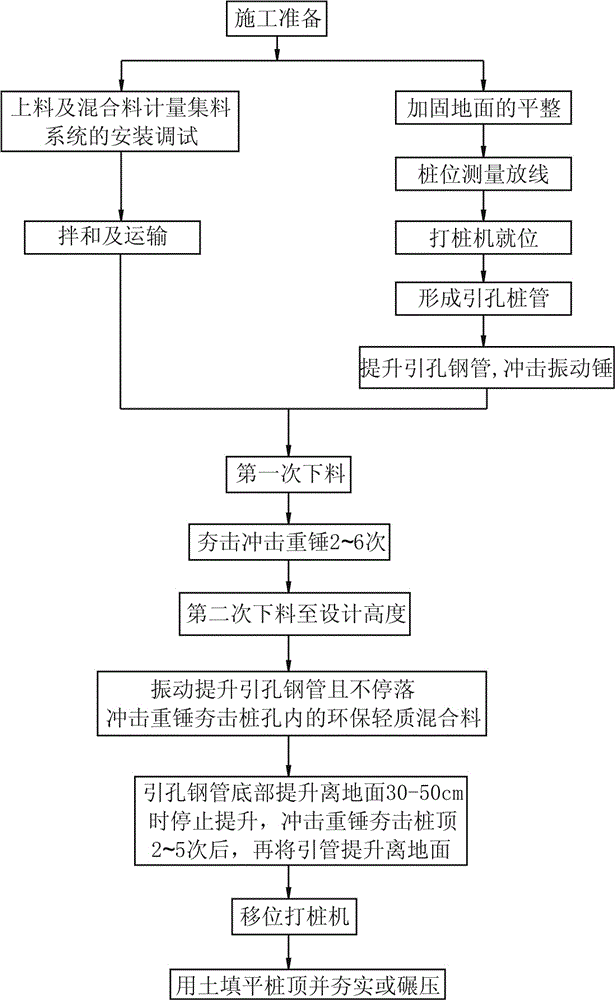

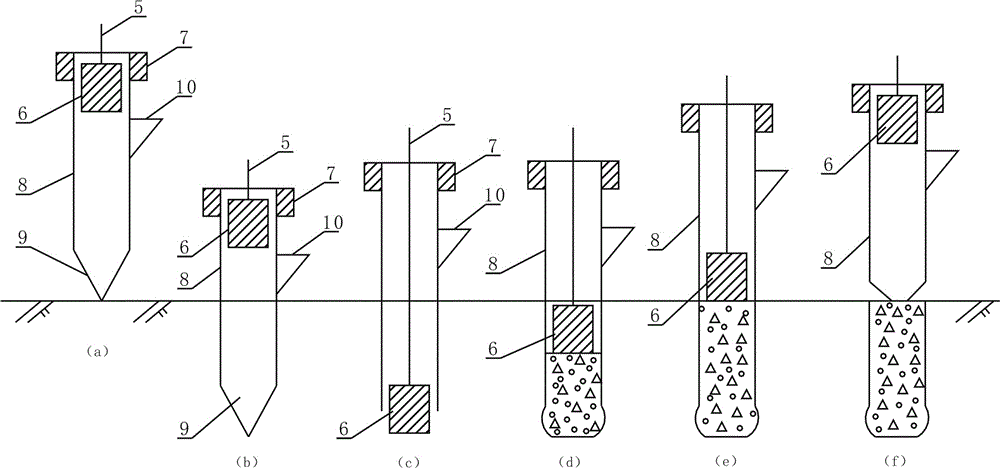

[0035] Embodiment 1: refer to Figure 1~Figure 3 Shown, the method for processing soft ground with environment-friendly lightweight material pile of the present invention, comprises the steps:

[0036] 1) Material preparation for environmentally friendly lightweight material piles: The materials for environmentally friendly lightweight material piles are the following three raw materials: ① quicklime, ② cement, ③ fly ash; according to the weight parts of each raw material: ① quicklime 1~ 8 parts, ② 1-3 parts of cement, ③ 2-9 parts of fly ash; select the above raw materials;

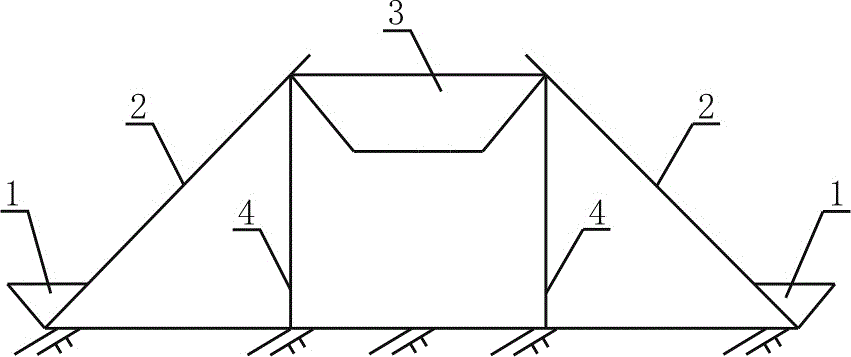

[0037] Put the above-mentioned raw materials into the fixed hopper 1 of the mixture metering and aggregate system, and input them into the mixing hopper 3 through the belt conveyor 2 and stir them evenly for 2~3 minutes to obtain light active materials (i.e., environmentally friendly light mixtures), and then It is directly unloaded from the mixing hopper into the hopper of the transport vehicle;

[003...

Embodiment 2

[0053] Basically the same as Example 1, the difference is that in step 1): the material preparation of the environmental protection lightweight material pile: the material of the environmental protection lightweight material pile is the following three kinds of raw materials: 1. quicklime, 2. waste gypsum, 3. slag; The parts by weight of each raw material are: ① 1-8 parts of quicklime, ② 0.01-2 parts of waste gypsum, and ③ 2-9 parts of slag; the above raw materials are selected.

[0054] Others are with embodiment 1.

[0055] It is proved by practice that the method of the invention is suitable for strengthening weak foundations such as silt, clay, sandy silt, peat soil, humus soil and the like, and has good reinforcement effect.

Embodiment 3

[0057] Basically the same as Example 1, the difference is that in step 1): the material preparation of the environmentally friendly lightweight material pile: the material of the environmentally friendly lightweight material pile is the following three raw materials: 1. quicklime, 2. sodium sulfate powder, 3. slag; According to the parts by weight of each raw material: ① 1-8 parts of quicklime, ② 0.01-1 part of sodium sulfate powder, and ③ 2-9 parts of slag; select the above raw materials;

[0058] Others are with embodiment 1.

[0059] It is proved by practice that the method of the invention is suitable for strengthening weak foundations such as silt, clay, sandy silt, peat soil, humus soil and the like, and has good reinforcement effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com