Non-stick dressing and preparation method thereof

A technology of adhesive dressing and polymer materials, which is applied in the field of medical hygiene/nanomaterials, can solve the problems of decreased water absorption and liquid absorption speed of dressings, affecting the speed of wound healing, and easy residue of oily substances, so as to reduce the adhesion of dressings and wounds , Improve the absorption capacity of exudate and reduce the pain of dressing change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

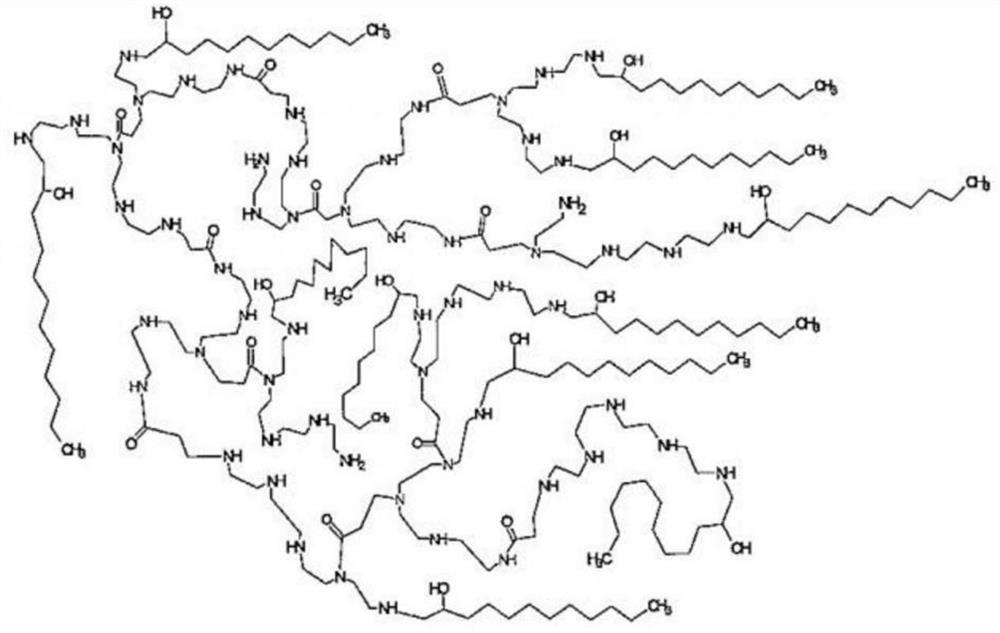

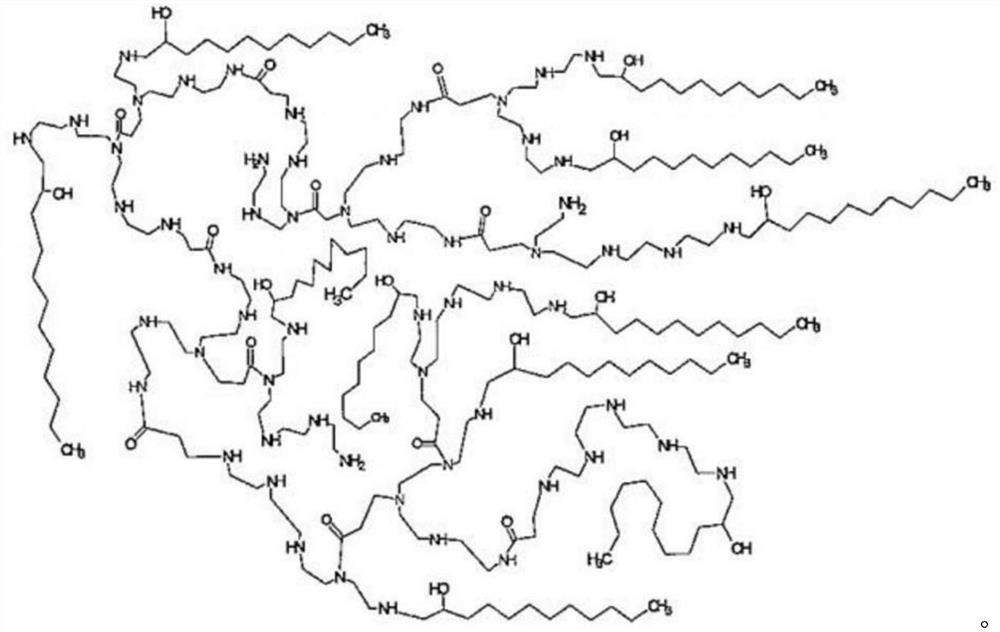

Method used

Image

Examples

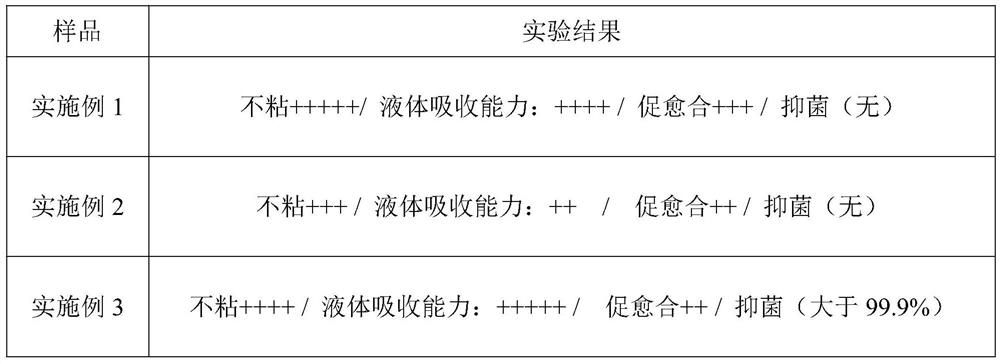

Embodiment 1

[0038] A non-stick dressing is composed of pure cotton non-woven fabric and a hydrophilic anti-adhesion layer, and the hydrophilic anti-adhesion layer is composed of PVP (k90) and PU. The preparation method of this non-stick dressing is as follows:

[0039] (1) Preparation of superhydrophilic polymer solution: Add 2g of PVP (k90) to a mixed solvent of 30mL diacetone alcohol and 10mL butanone measured in advance and stir to dissolve it to obtain solution A. Add 2g PU to the pre-measured Stir in a mixed solvent of 30mL diacetone alcohol and 10mL butanone to dissolve it to obtain solution B; then mix the dissolved A and B solutions at a volume of 2:1 and mix well to form a superhydrophilic polymer solution;

[0040] (2) Substrate preparation and treatment: put the pure cotton non-woven fabric material into a vacuum drying oven, and vacuum dry for 30 minutes;

[0041] (3) Substrate coating treatment: soak the treated gauze in the superhydrophilic polymer solution, press to remov...

Embodiment 2

[0044] A non-stick dressing is composed of ordinary medical gauze and a hydrophilic anti-adhesion layer, and the hydrophilic anti-adhesion layer is composed of PEGMn4000. The preparation method of this non-stick dressing is as follows:

[0045] (1) Preparation of super-hydrophilic polymer solution: Take 2 g of PEG Mn4000 and add it into 500 mL of purified water and stir for 1 h to fully dissolve;

[0046] (2) Substrate preparation and treatment: ordinary medical gauze material, put it in a vacuum drying oven, dry it in vacuum for 30 minutes, take out the gauze, put it into a plasma cleaning machine, and plasma treat both sides for 3 minutes each (you can increase the amount of gauze and hydrophilic waterproof the binding effect of the adhesive layer);

[0047] (3) The treated yarn is placed in the superhydrophilic polymer solution and immersed for 30 minutes, then taken out, taken out and dried at 100°C to obtain the modified gauze;

[0048] (4) product, package, and sterilize...

Embodiment 3

[0050] A non-stick dressing is composed of medical absorbent cotton gauze and a hydrophilic anti-adhesion layer, and the hydrophilic anti-adhesion layer is composed of PVP and chlorhexidine acetate. The preparation method of this non-stick dressing is as follows:

[0051] (1) Preparation of superhydrophilic polymer solution: 3g of PVP (k90), 0.05g of chlorhexidine acetate were dissolved in 5000mL of alcohol;

[0052] (2) Substrate preparation and treatment: put medical absorbent cotton gauze into a vacuum drying oven, and vacuum dry for 30 minutes;

[0053] (3) Substrate coating treatment: soak the treated gauze in the superhydrophilic polymer solution, press to remove excess liquid, and dry to obtain the modified gauze;

[0054] (4) product, package, and sterilize to obtain a non-stick dressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com