Hybrid power machine

A power machine and engine technology, applied in the direction of engine components, machines/engines, non-variable engines, etc., can solve the problems that inertia resistance and fluid resistance cannot be eliminated, the effect is not very obvious, and the intensity of start-up energy flow is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

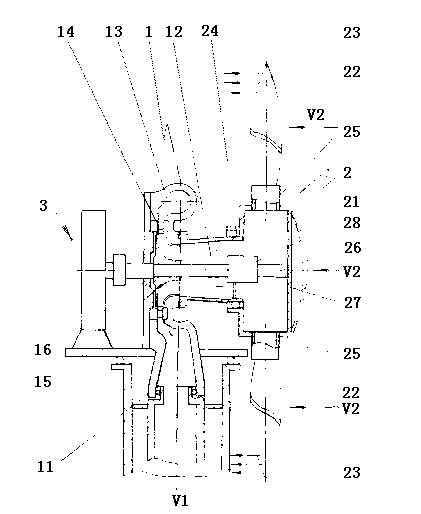

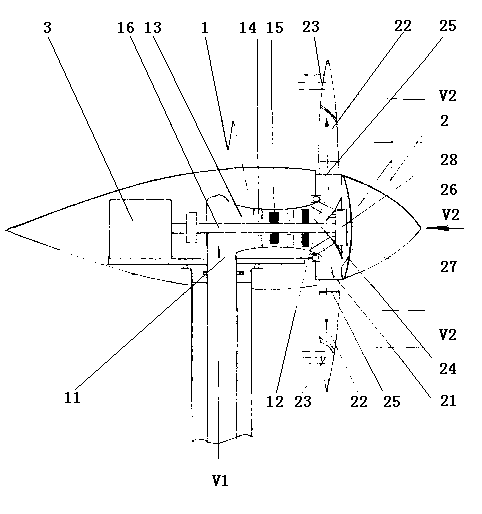

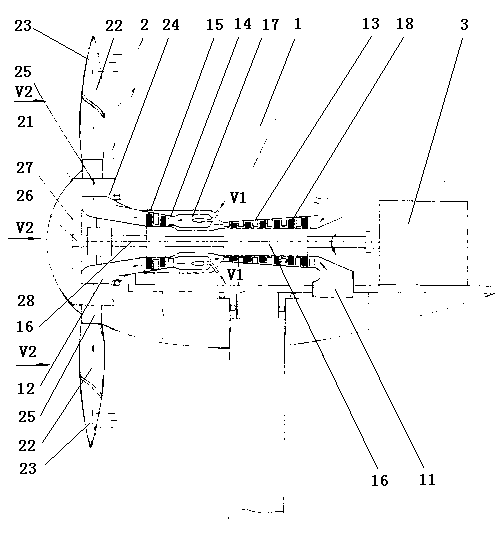

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

[0035] Such as figure 1 A kind of hybrid power machine shown is mainly composed of A type energy flow engine, B type energy flow engine and working machine 3 couplings, and said A type energy flow engine is composed of inlet port 11, discharge port 12, worm gear Outer stator and inner rotor expansion power machine 1 composed of shell 13, jet ring 14, impeller 15, impeller shaft 16, etc.; the type B energy flow engine is composed of hub 21 and hollow blades 22 installed around the hub 21 Horizontal shaft lift type impeller 2, the inner cavity of hollow blade 22 communicates with the inner cavity of hub 21, and the trailing edge portion 23 of hollow blade 22 is provided with a jet hole; the hub 21 is a hollow rigid shell with a Needed inflow hole 24, outflow hole 25 and installation hole, various components are assembled on the wheel hub for sealing installation; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com