Multistage blade mud pump for riserless subsea mudlift drilling

A technology of riser and mud pump, which is applied to components of pumping devices for elastic fluids, pumps for special fluids, pumps, etc., which can solve the problems of lift pump module reliability, reduced maintainability, poor subsea reliability, Low efficiency and other problems, to achieve the effect of reducing the performance requirements of solid-liquid sealing, stable work without pulsation, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

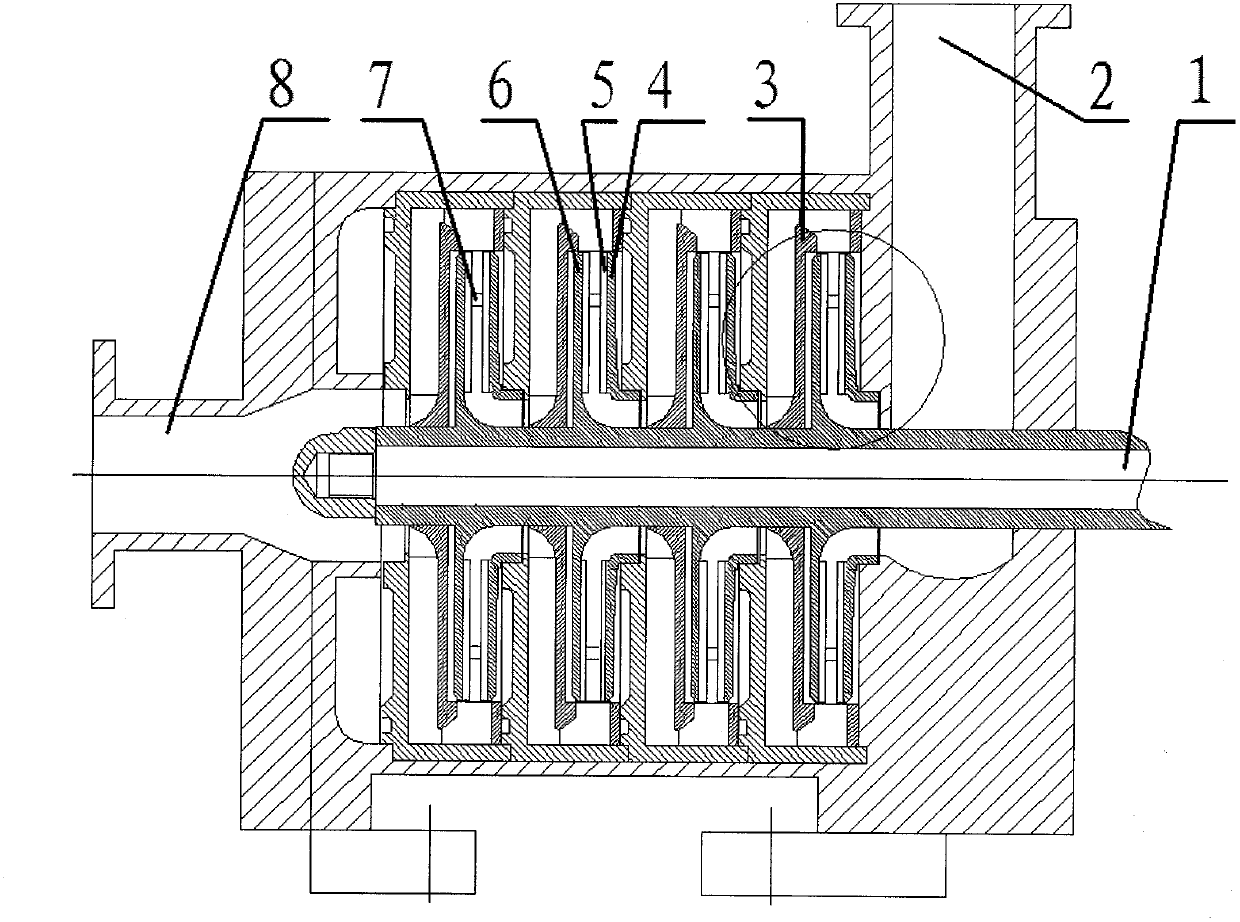

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] refer to figure 1 It is a structural diagram of an embodiment of a multi-stage vane mud pump. When the pump is working normally, the subsea motor drives the drive shaft to run, and the drive shaft drives the impeller cover plate to run through the key. The returned drilling fluid and cuttings pass through the multi-stage pump inlet 2, disc The work done by the impeller is further introduced into the guide vane 3, thereby completing a single-stage blade mud pump cycle, and the work is done by the multi-stage unit to reach the required lift of the pump, and finally returns to the sea surface through the return pipeline connected to the pump outlet 8.

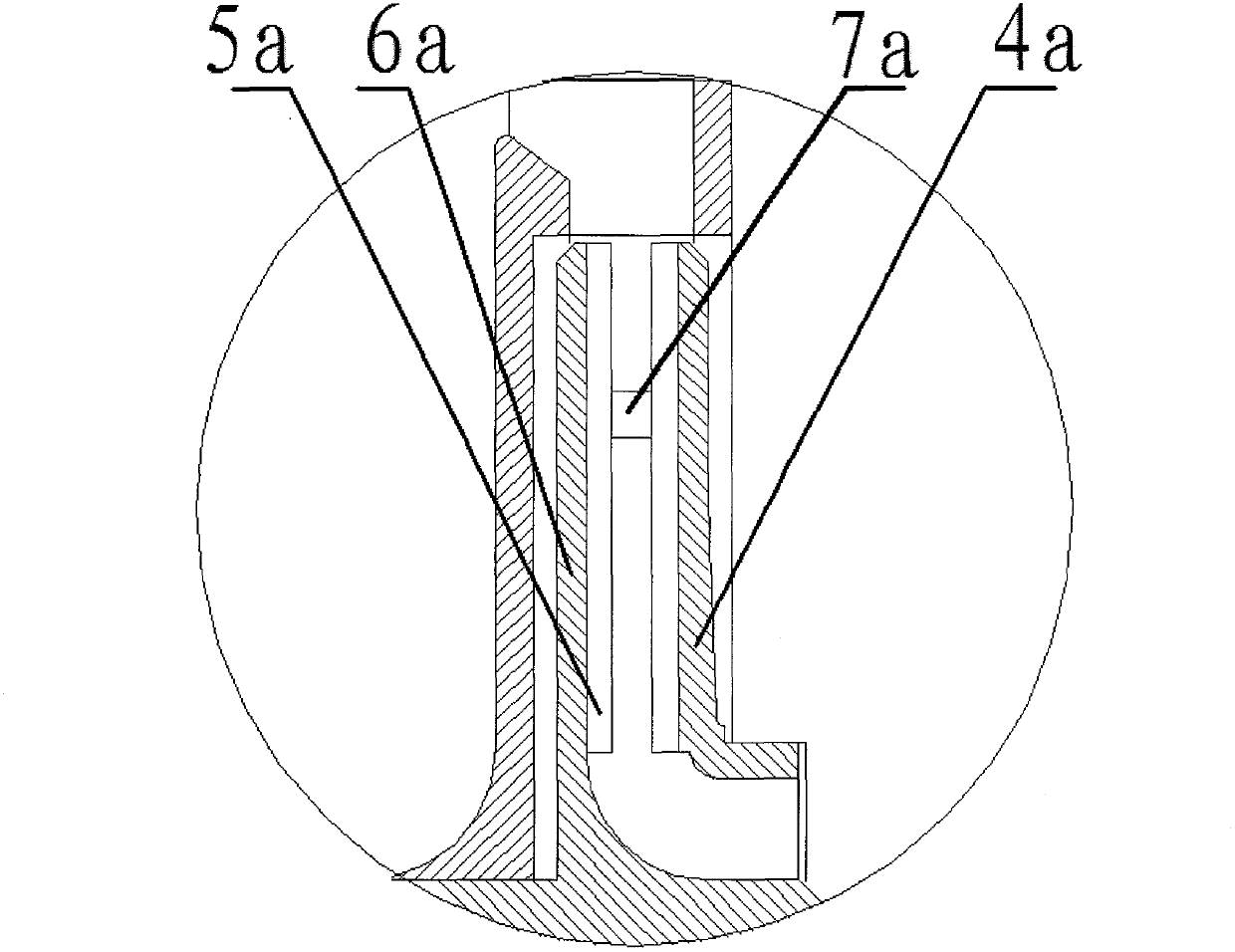

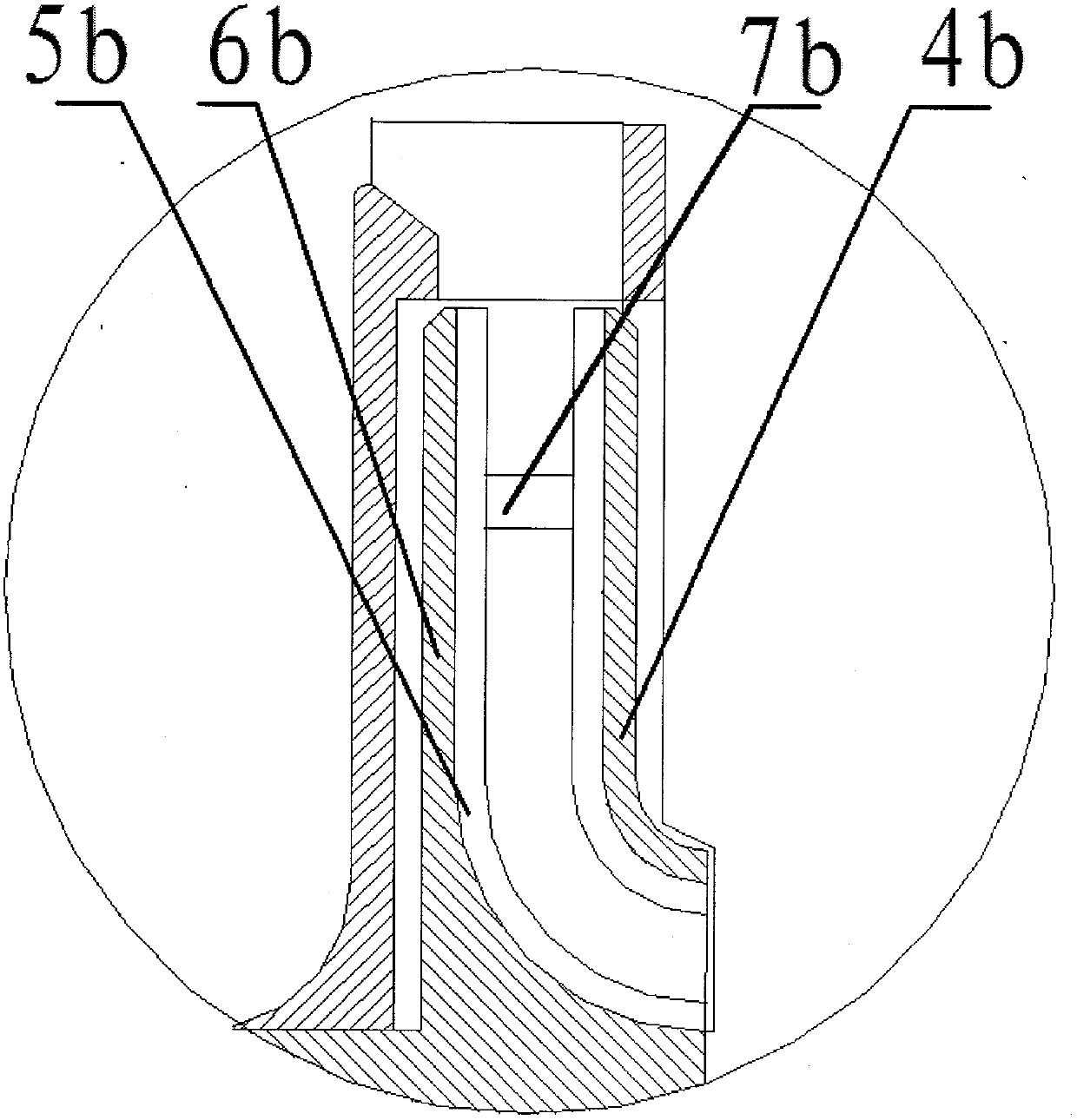

[0024] Because there are radial blades 5 between the driving impeller cover plate 6 and the driven cover plate 4, the flow head performance curve of the single-stage disc impeller is relatively flat,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com