Patents

Literature

33results about How to "No pulse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

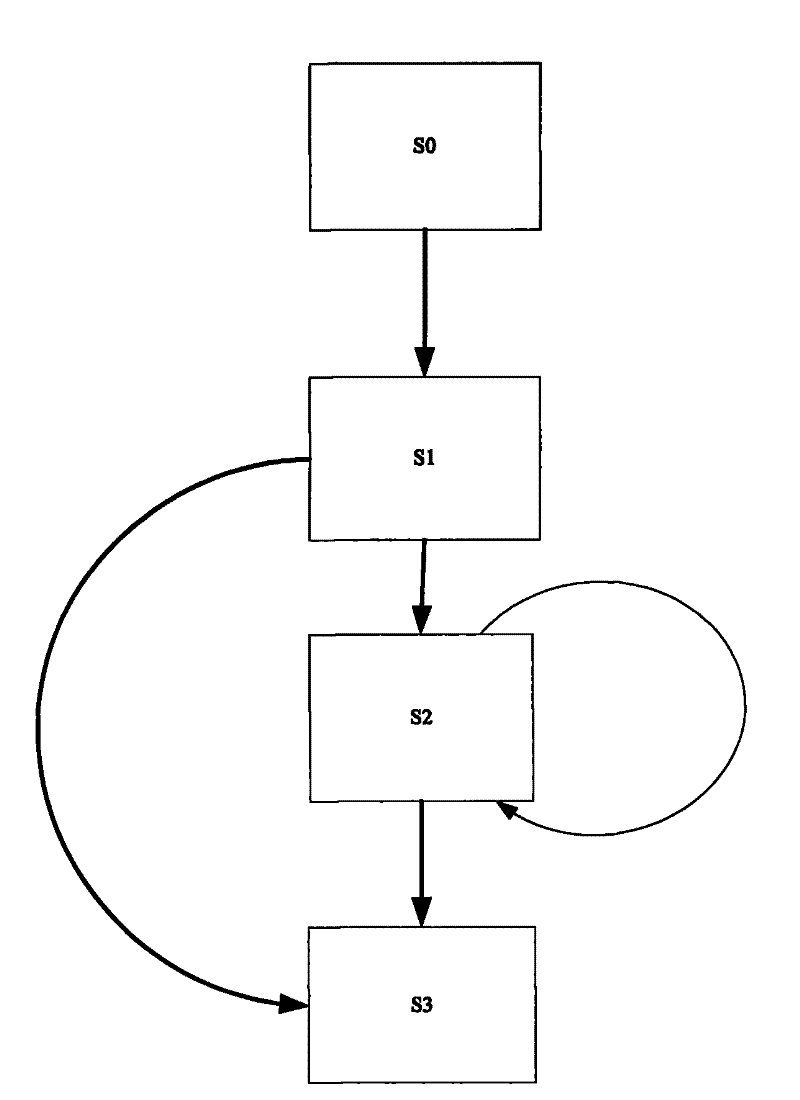

Precision control method and device for adding micro-liquid

InactiveCN101833293AEasy inputIncrease productivityProgramme control in sequence/logic controllersElectric machineryMemory circuits

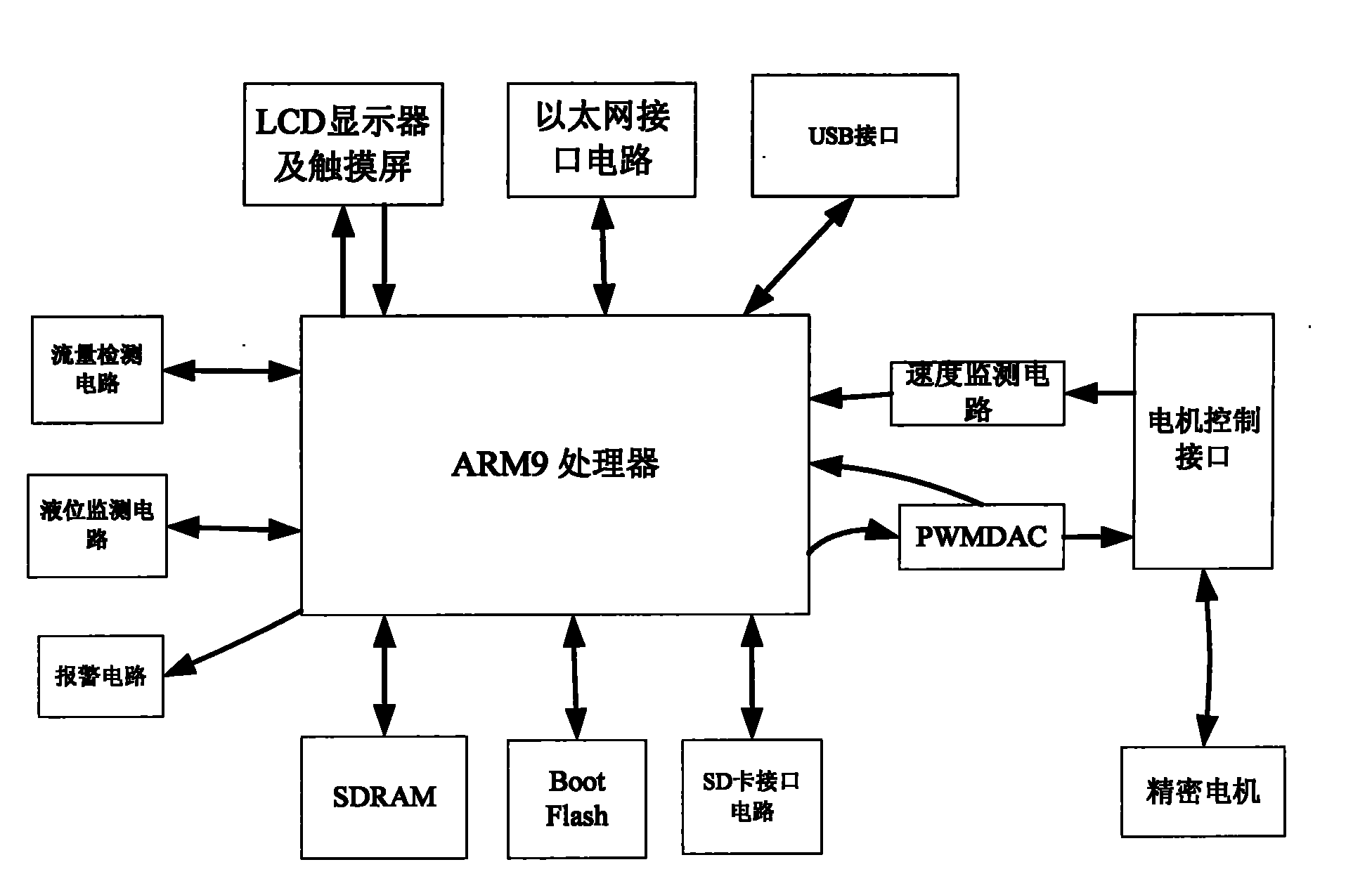

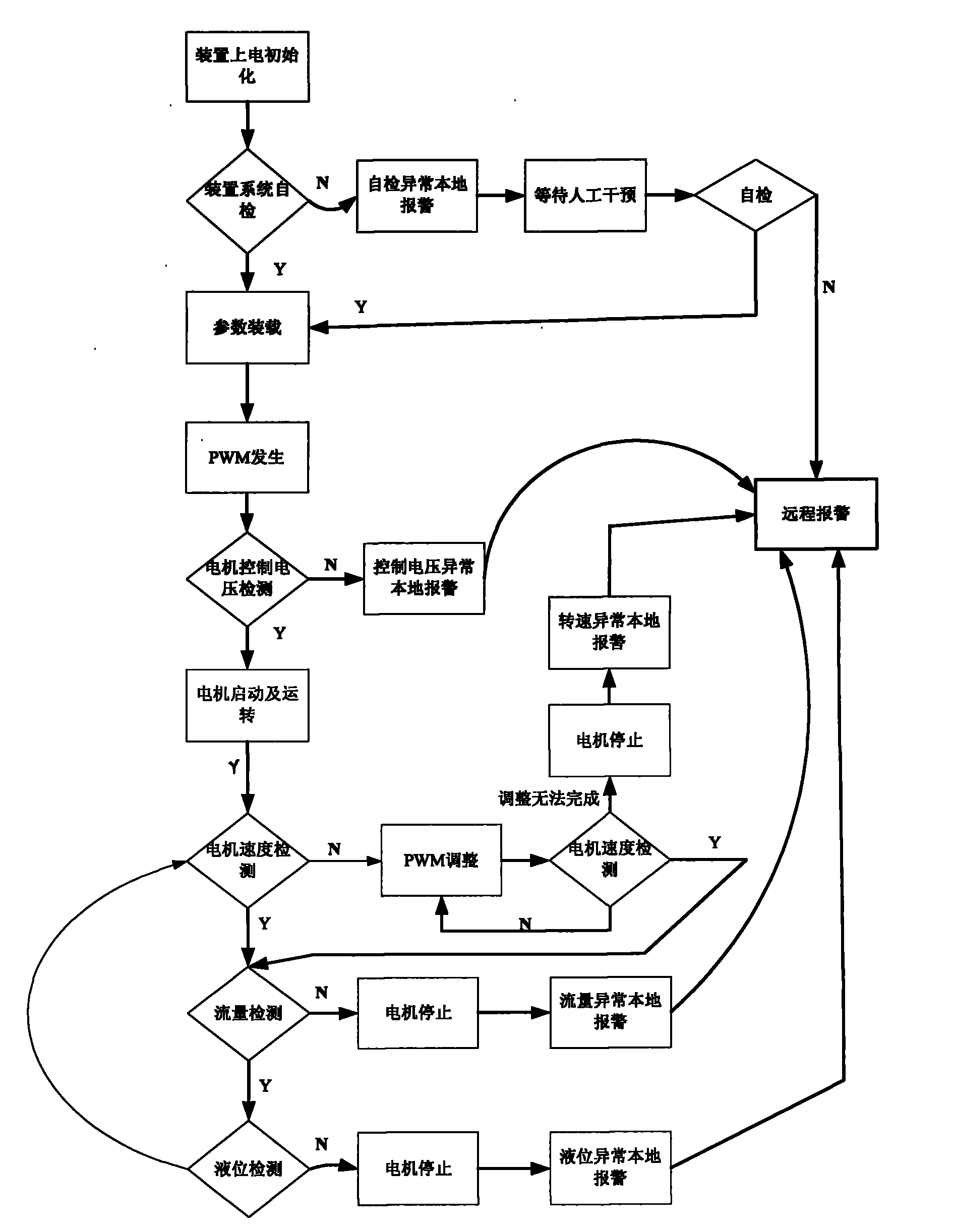

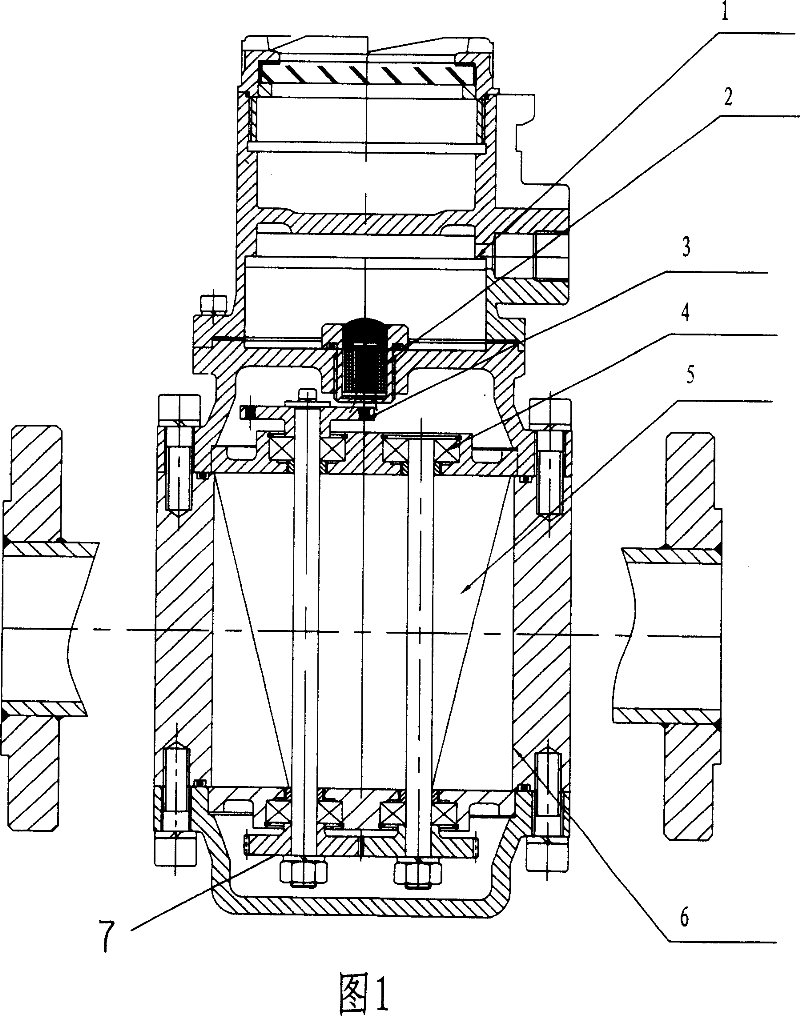

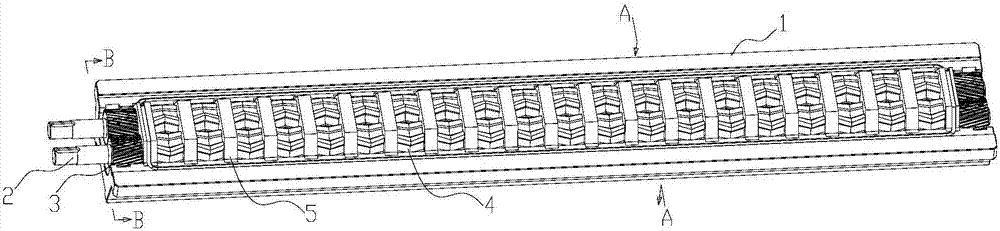

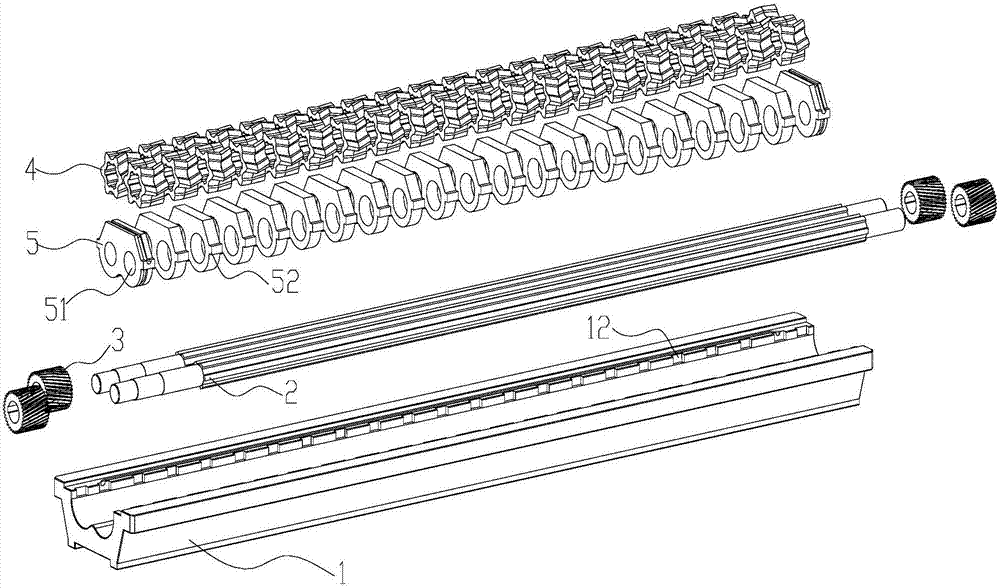

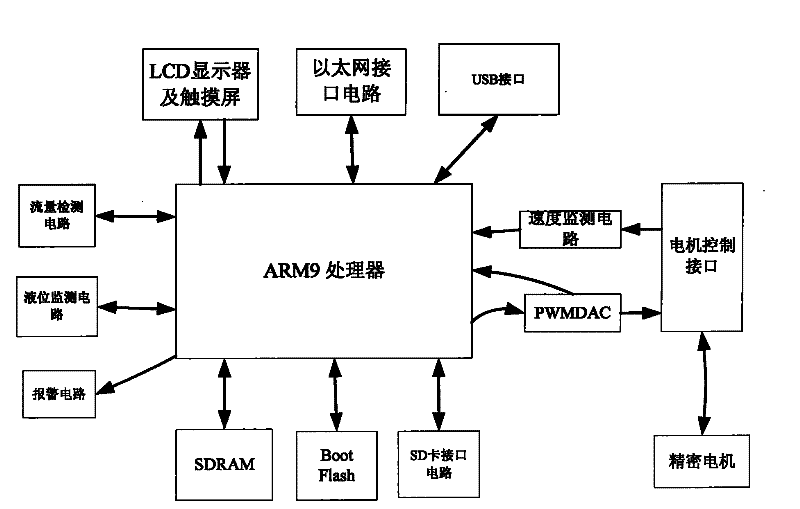

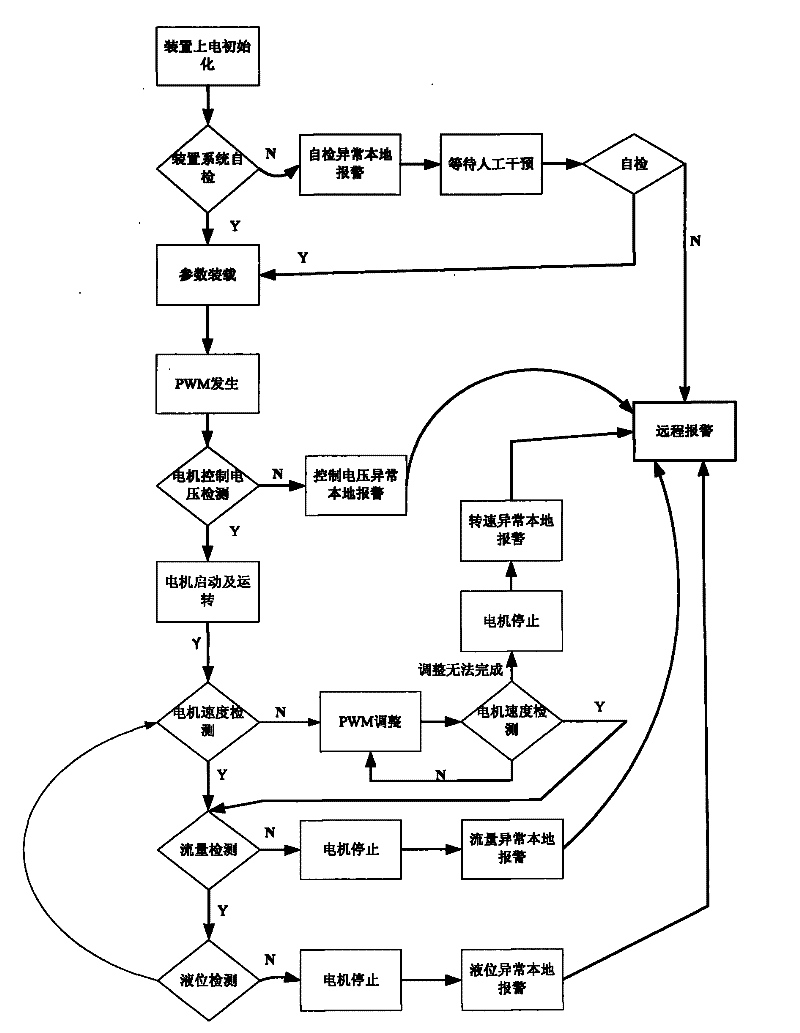

The invention discloses a precision control method and a precision control device for adding micro-liquid. The precision control device comprises an ARM9 processor, a color LCD display touch screen, an Ethernet interface circuit, a high-precision speed regulation circuit, a speed monitoring circuit, a flow detection circuit, a liquid level monitoring circuit, an alarm circuit, an SD card interface circuit, a USB interface circuit, a PWMDAC circuit, an SDRAM memory circuit, a program memory circuit flash, and a motor control interface circuit, wherein the circuits are mutually connected and the precision control for adding the micro-liquid addition is realized by software programming. By using the rate tracking technology to timely change the needed liquid flow, the precision control method and the precision control device for adding the micro-liquid realize the accurate control of micro-liquid addition in the production process, achieve the control precision of 1 percent, and have the functions of local automatic alarm and remote automatic alarm under the abnormal condition. The precision control method and the precision control device have convenient control parameter input, and can be organically integrated with the conventional production equipment to greatly improve the production efficiency and save the production cost.

Owner:EAST CHINA NORMAL UNIVERSITY

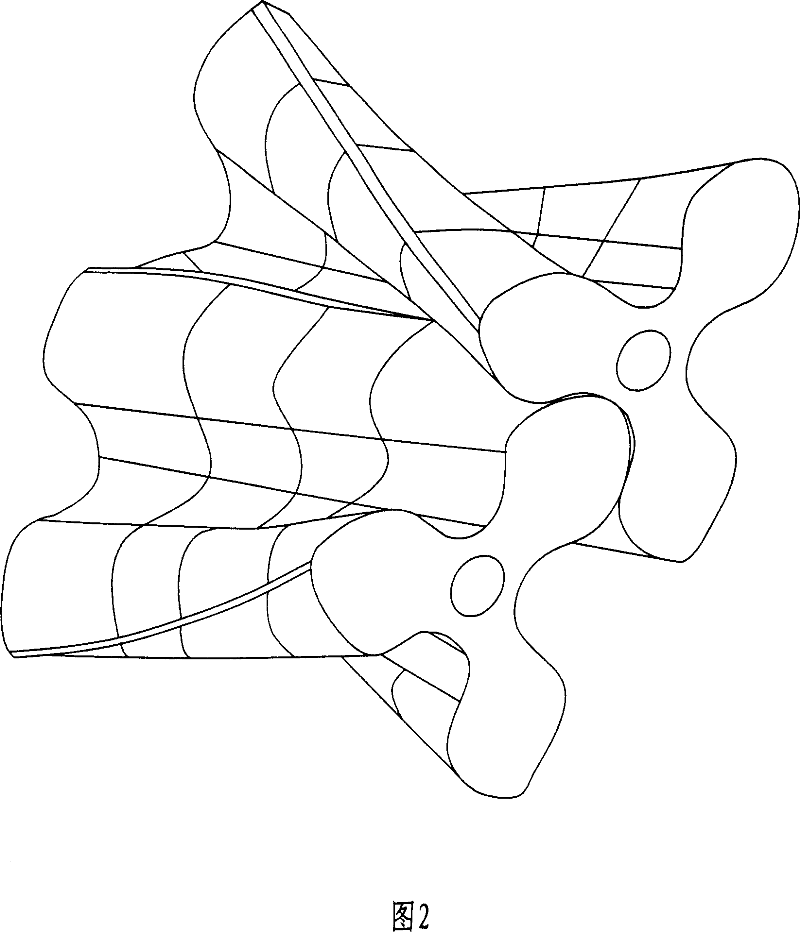

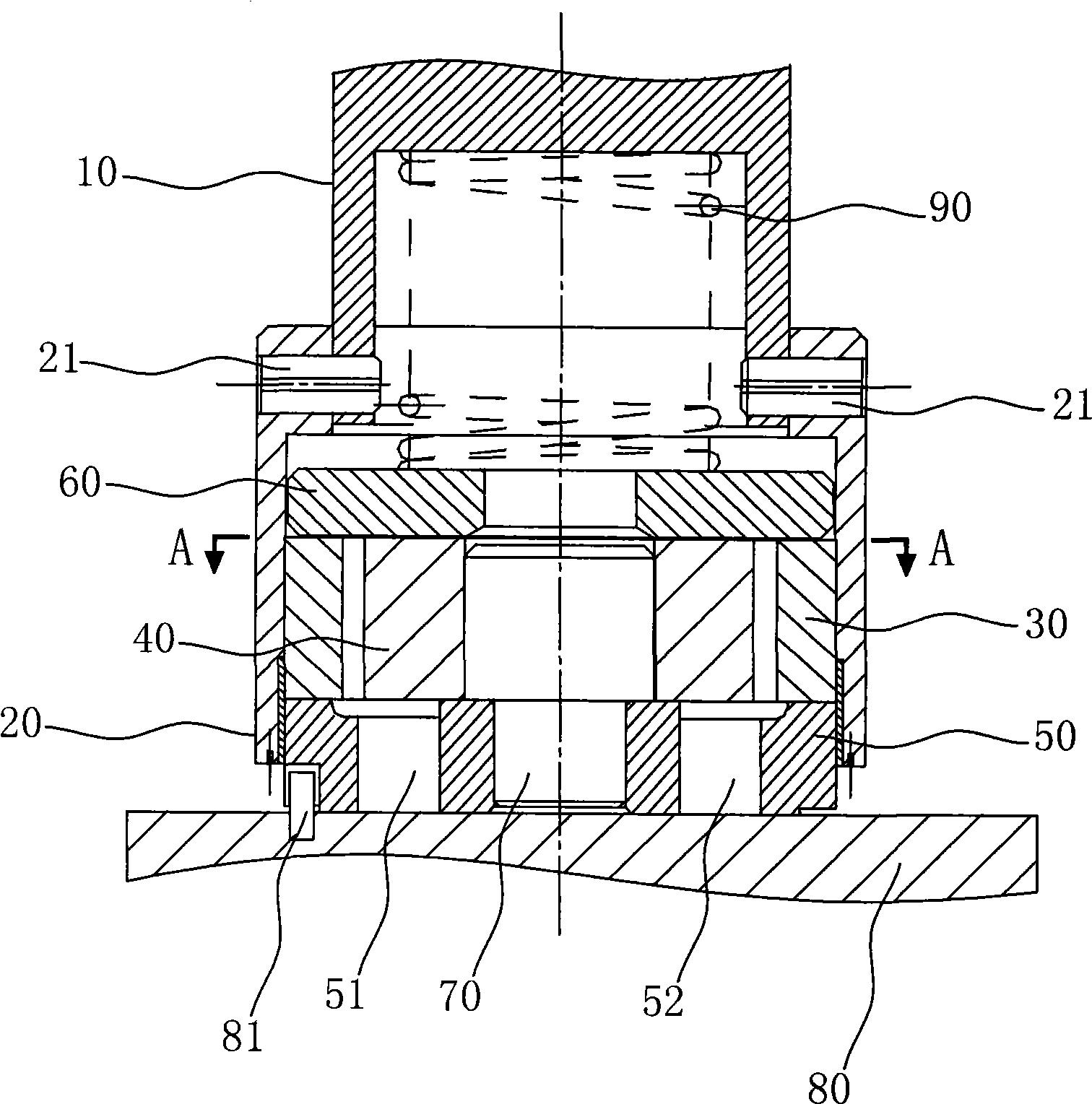

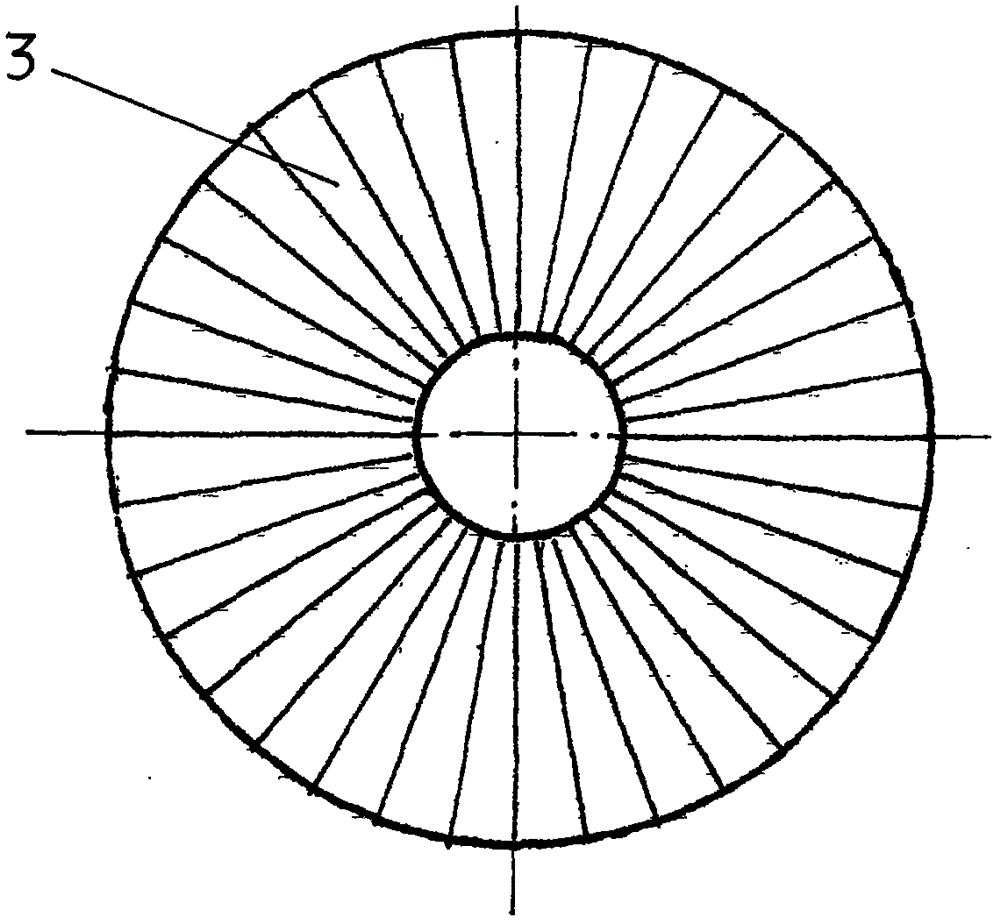

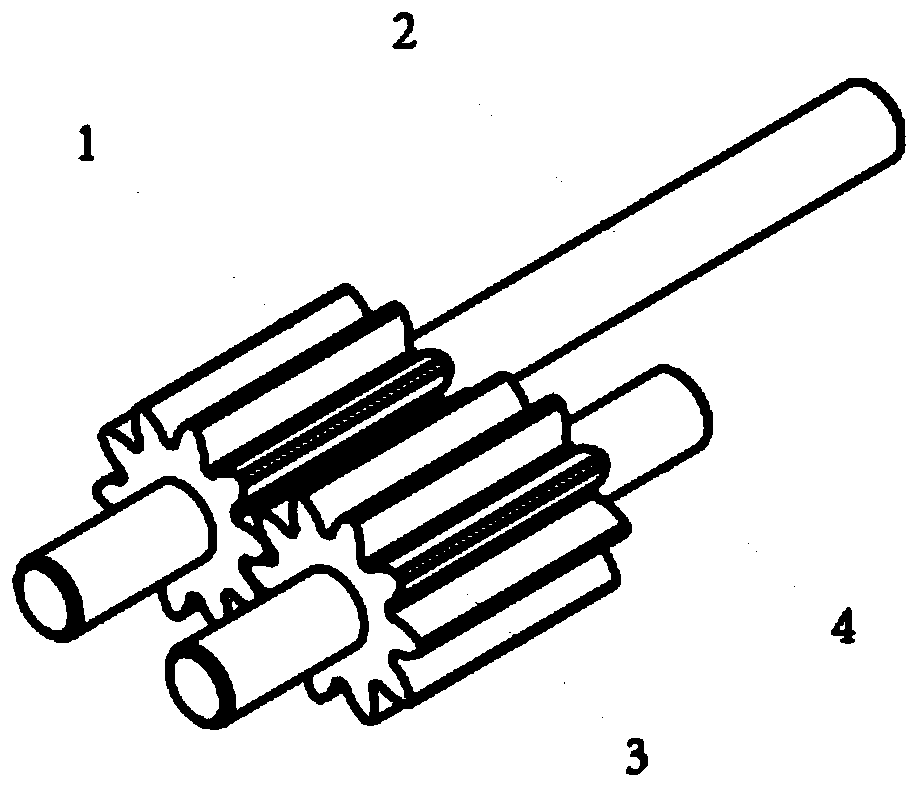

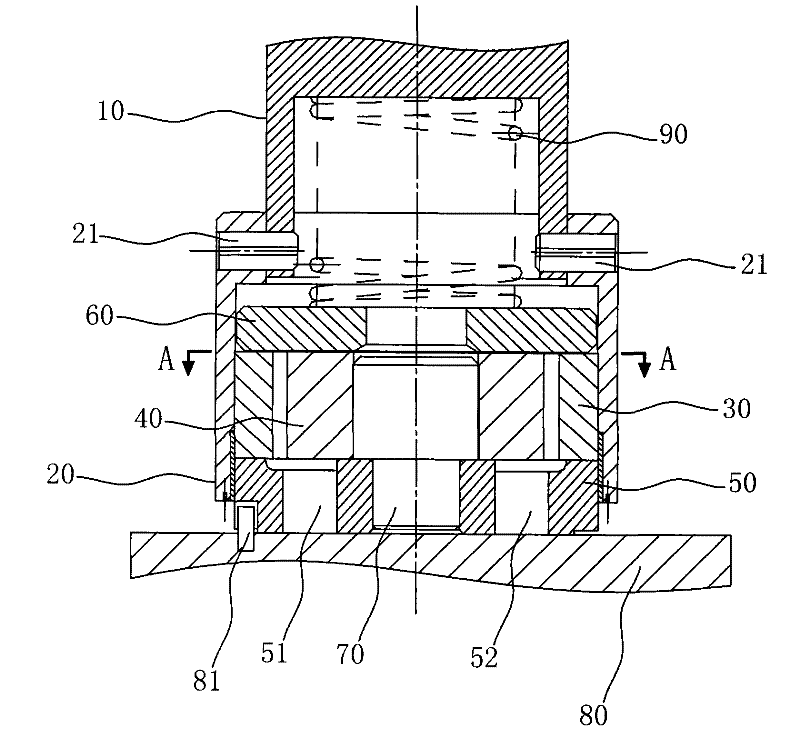

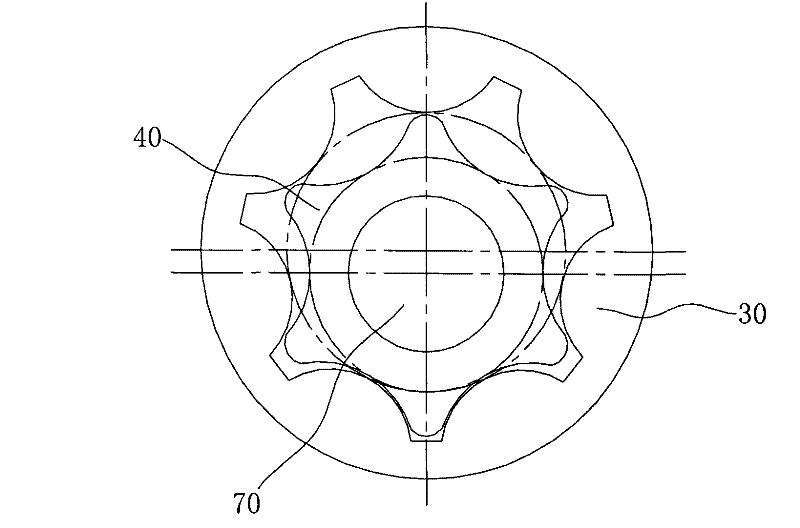

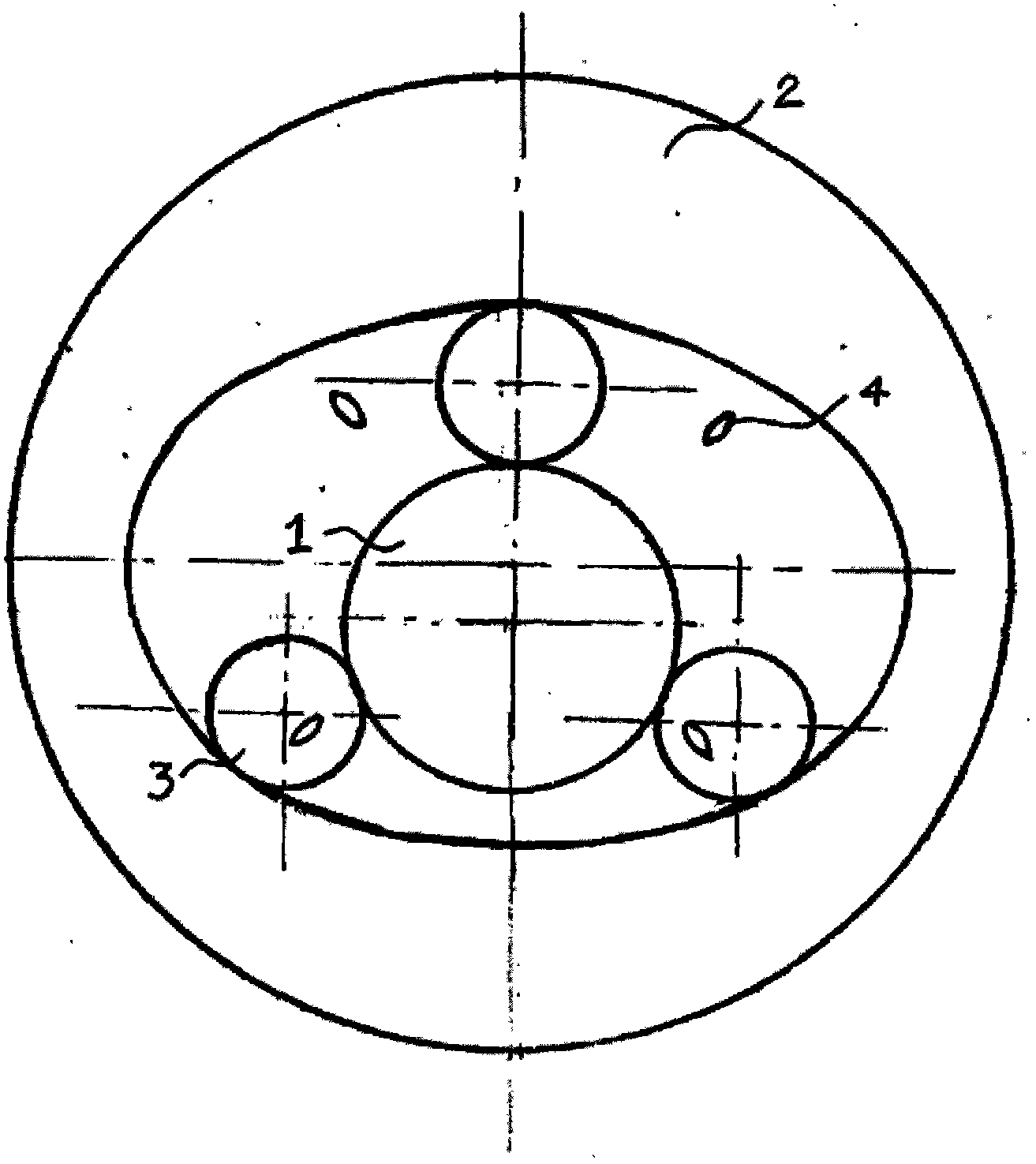

3-teeth double-rotor flowmeter

InactiveCN101042301AImprove contact strengthNot easy to pittingVolume indication and recording devicesVolume/mass flow by mechanical effectsEngineeringNatural gas

This invention relates to one three-gear gas and double rotor flow meter for natural gas and coal gas, which comprises the structure as: meter chamber is connected to transfer magnetic steel, sensor, electrical meter, wherein, meter chamber has rotors; the rotor is for three gear spiral rotor in arc swing shape; the gear is composed of four section curves from tip to long swing line, short line and opening line and arc line; meter chamber connects double rotor through bearing and drive gear; the double rotor axis front end is connected to drive gear geared with two drive gears; one rotor back end is fixed on emission magnetic steel.

Owner:SHANGHAI YINUO INSTR

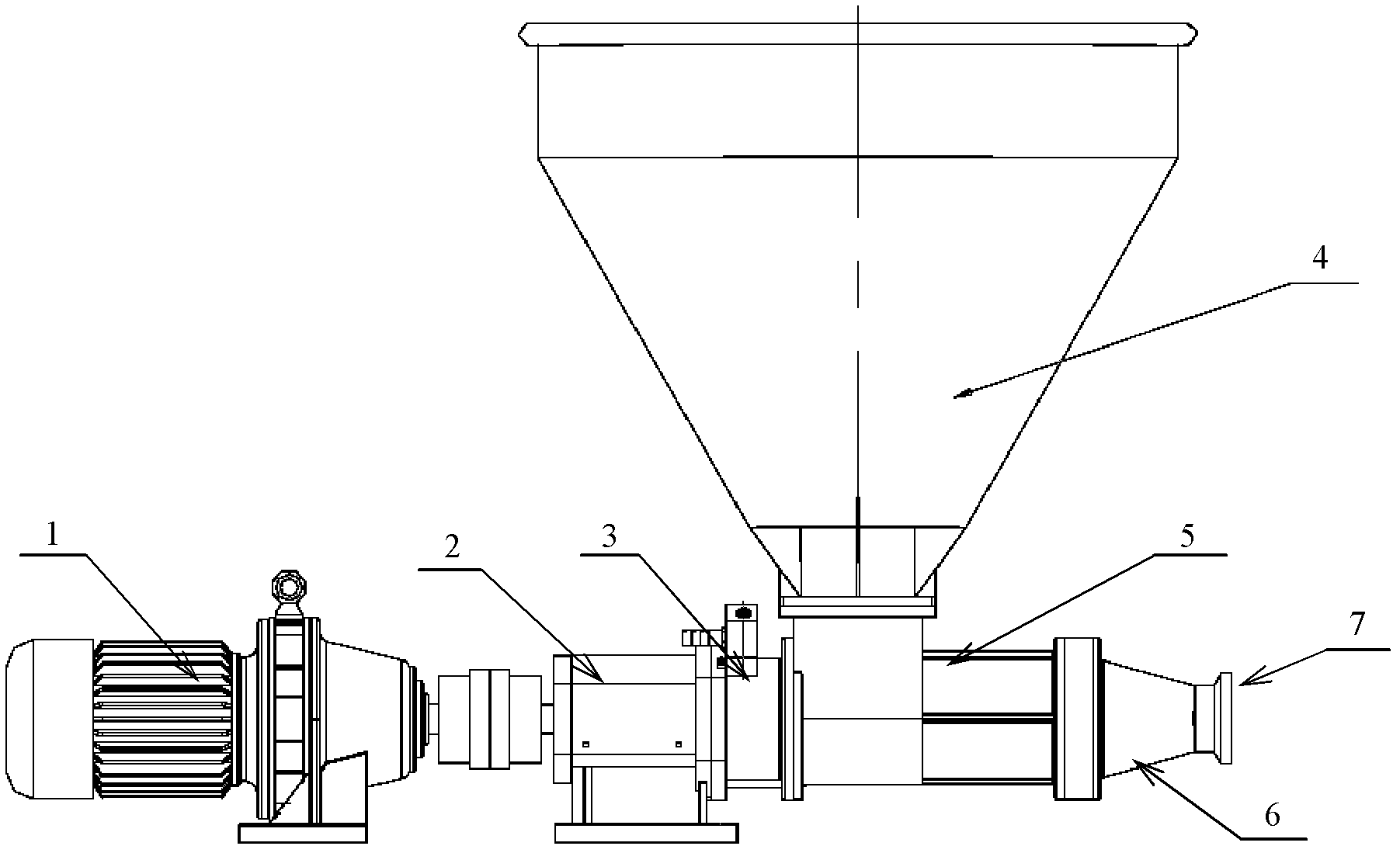

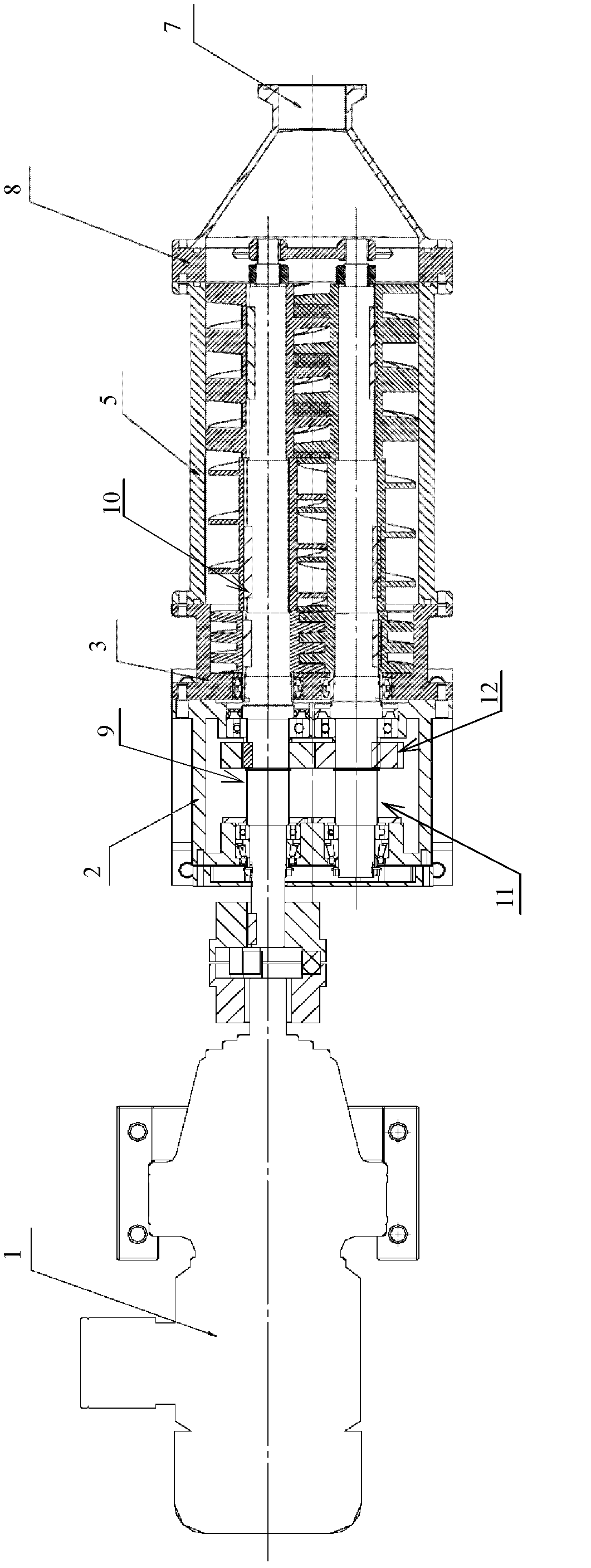

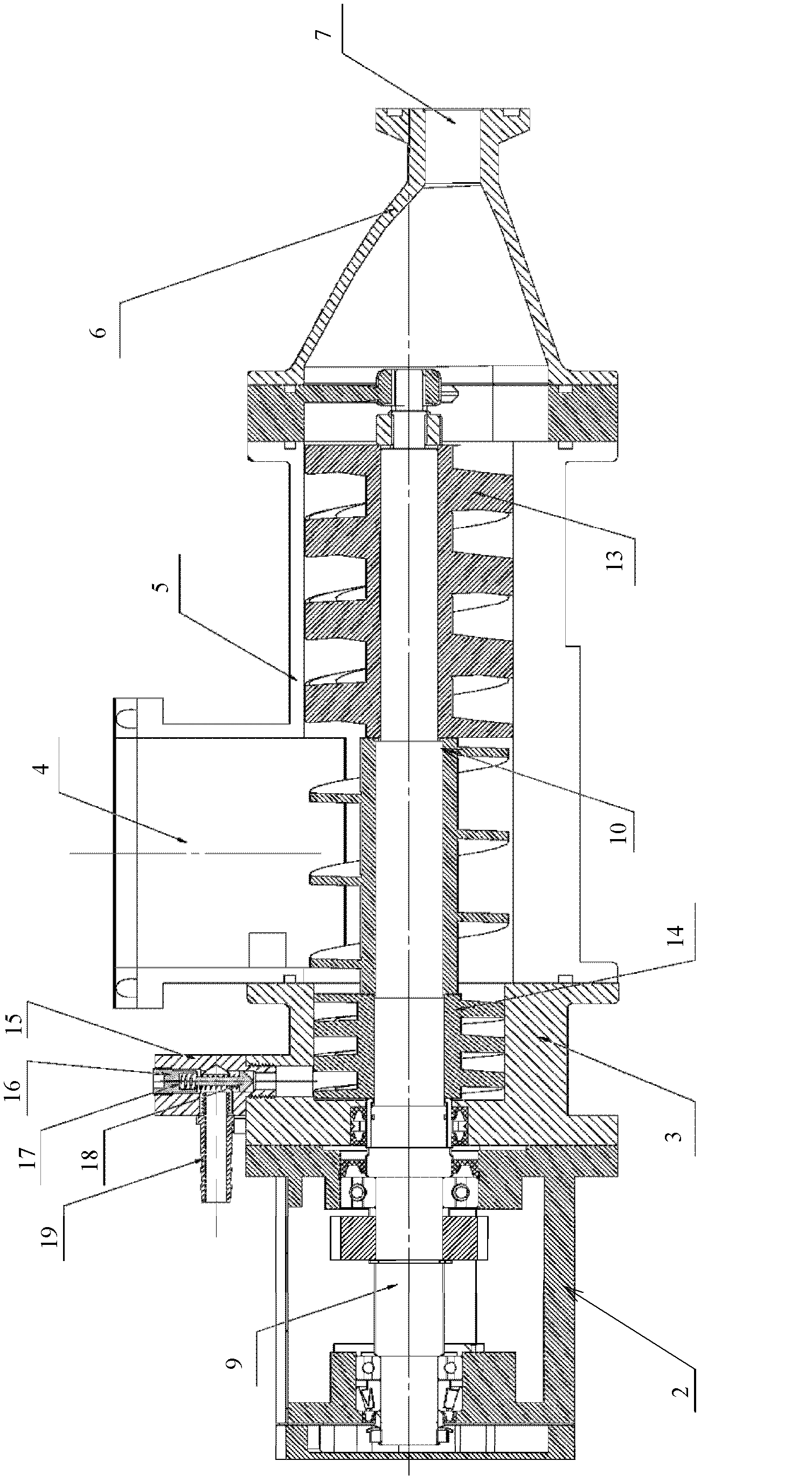

Vacuum screw-rod delivery pump

The invention relates to a vacuum screw-rod conveying pump which comprises a feed cavity and a discharge cavity, wherein the feed cavity and the discharge cavity are mutually communicated; a feed inlet is arranged above the feed cavity, and an end of the discharge cavity is provided with a discharge outlet; the other side (opposite to the discharge cavity) of the feed cavity is communicated with a vacuum cavity, the vacuum cavity is provided with an air release valve, a screw rod driven by a motor sequentially passes through the vacuum cavity and the feed cavity, and the screw rod is provided with a spiral body. In the vacuum screw-rod conveying pump provided by the invention, through utilizing the motion mode of the screw rod and setting the vacuum cavity on one side of the feed cavity, the removal of air in materials is facilitated; and because the spiral thrusting force offsets a vacuum attractive force, materials are uneasy to enter into the vacuum cavity, and only air is pumped out. The vacuum screw-rod conveying pump can be used for conveying various materials, and therefore, the vacuum screw-rod conveying pump is wide in viscosity range, large in output volume, stable in conveying and high in operating efficiency.

Owner:BEIJING YANGHANG KEMAO CO LTD

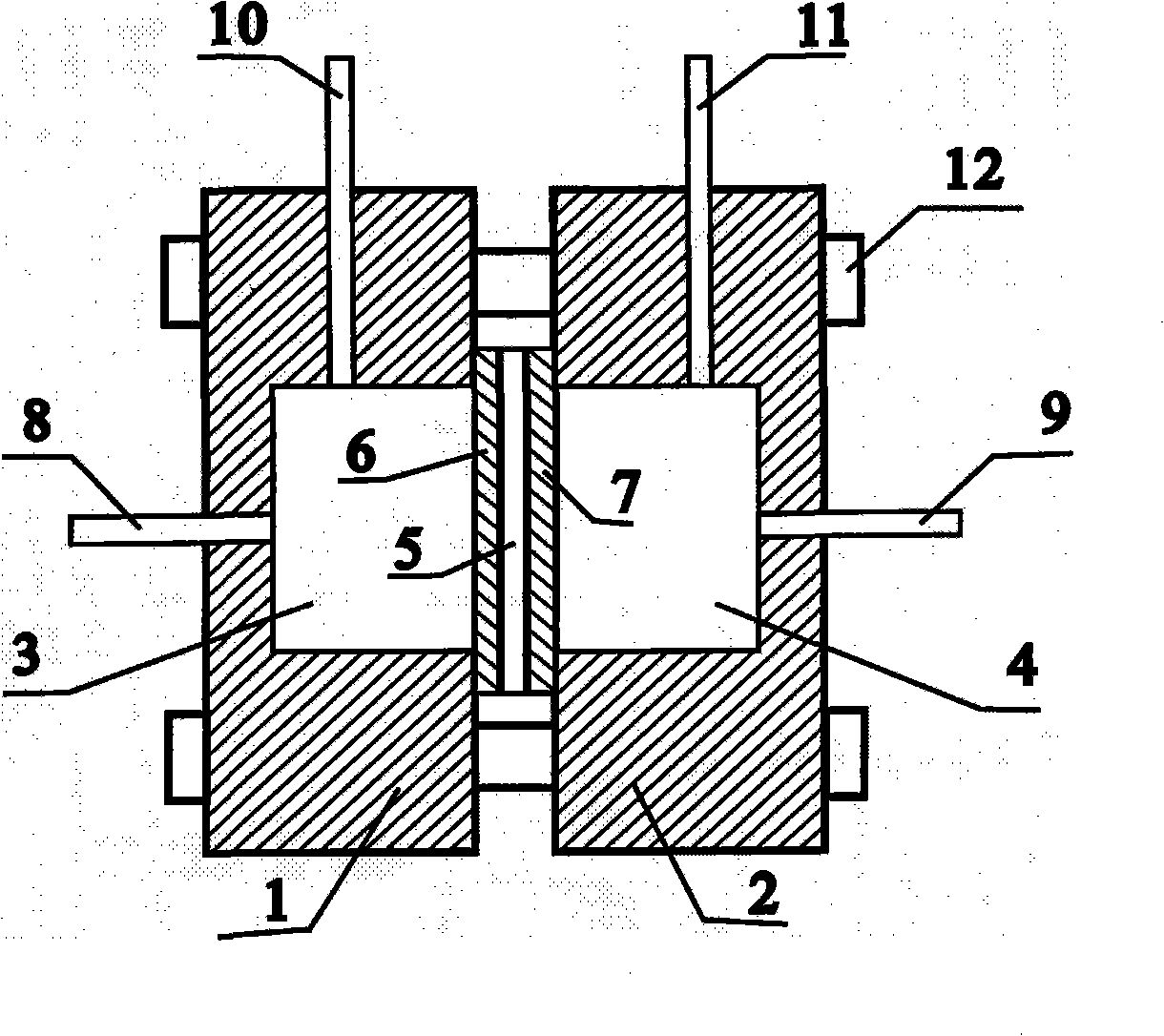

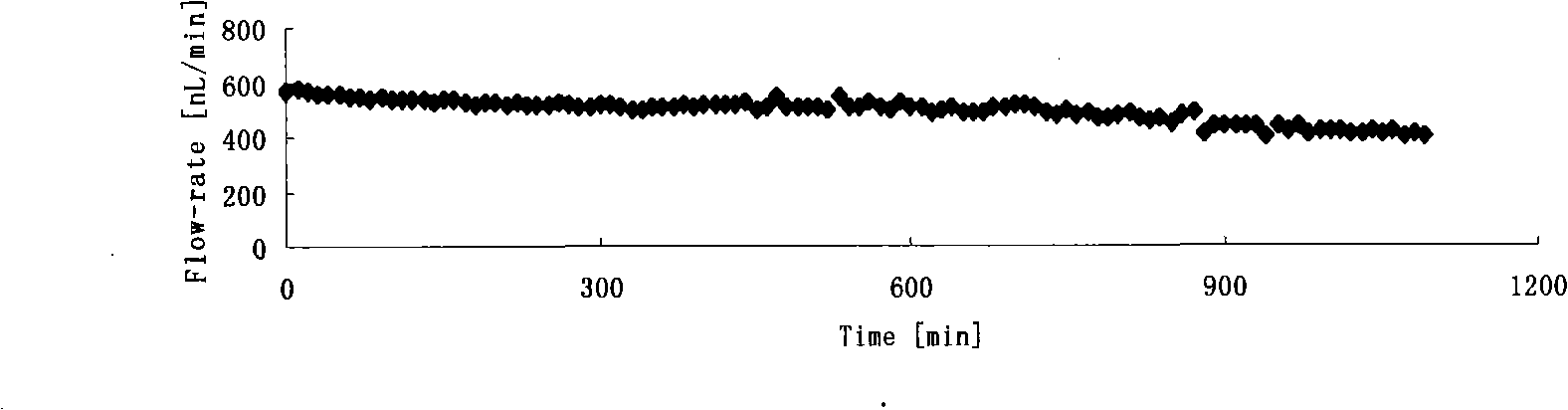

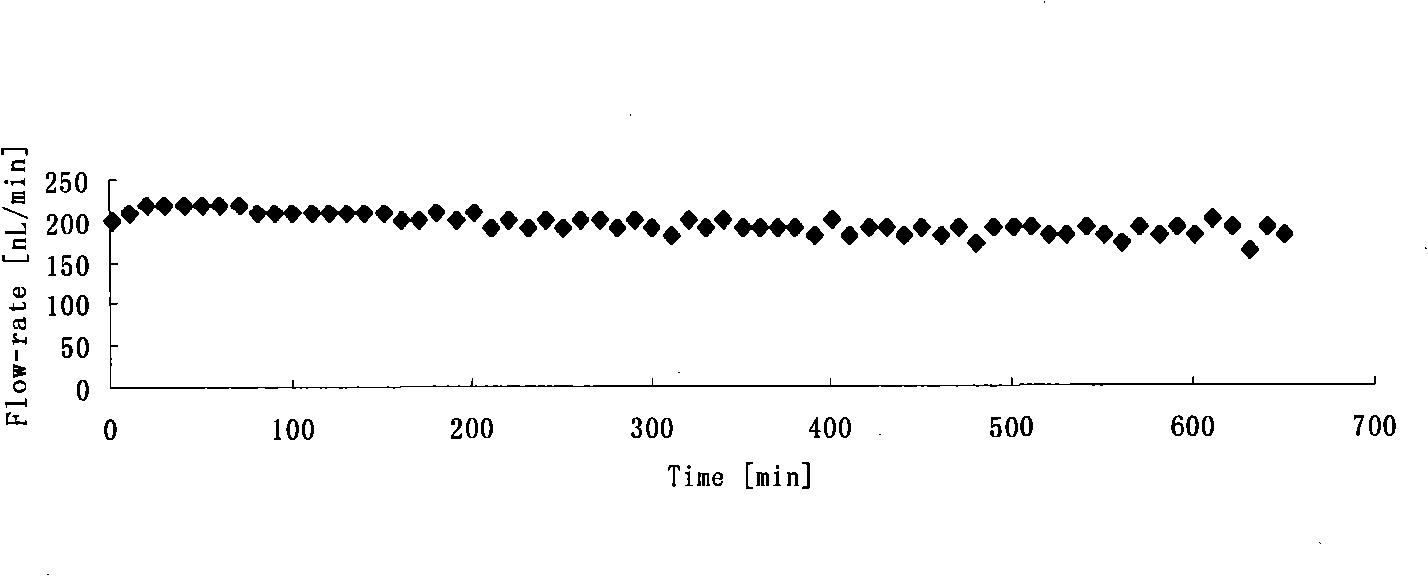

Microfluid drive unit based on infiltration

The invention relates to a microflow driving device based on osmosis. Two floor plates sandwiched by a semipermeable membrane and installed between two tank bodies of aqua storage tanks with constant volume body and connected by bolt and nut. Two tank bodies all have one vent of aqua storage tank. One inlet or outlet of one aqua storage tank is provided on the outer sidewalls of the two tank bodies and one opening communicated with the cavity for storing liquid is respectively on the corresponding point of the inner wall of the two tank bodies. The minipores are all dispersed on the two floor plates, wherein the aperture diameter of minipore is 0.4-2mm and the cutoff molecular weight of semipermeable membrane is less than the molecular weight of infiltration driving agent. On running, the aqua storage tank is filled with deionized water and another aqua storage tank is filled with infiltration driving agent, therefore the gas of the two aqua storage tanks are removed and the flow speed and stability of micropump can be measured after closing the vent. The whole structure is simple and the cost is low. The microflow driving device is convenient for carrying without external resource and continuously serves for many days and the liquid flow is stable, adjustable without pulse.

Owner:NORTHEASTERN UNIV

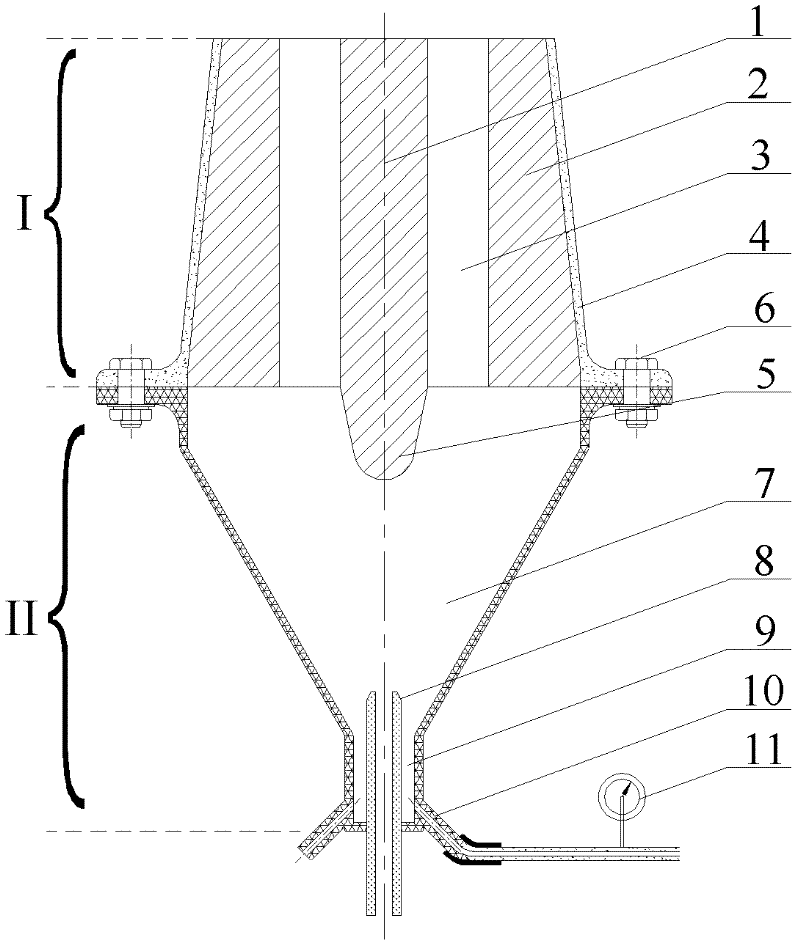

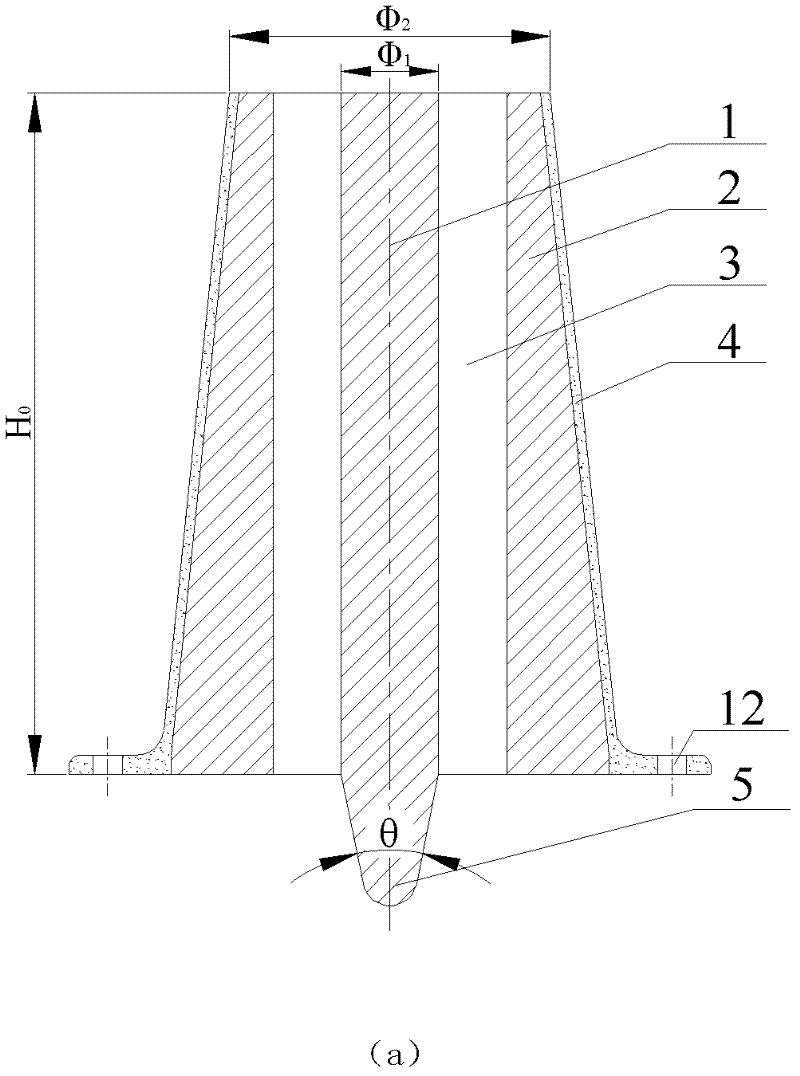

A device for blowing and spraying powder at the bottom of a ladle in a cyclone-protected gas storage chamber

The invention discloses a ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber, and belongs to the technical field of steel smelting. The ladle bottom blowing power injection device with a whirlwind-type flow-smoothing gas storage chamber comprises a slit-type powder injection component I and the whirlwind-type flow-smoothing gas storage chamber II.A fire-resistant material is filled into the slit-type powder injection component. Multiple slits are distributed uniformly in the fire-resistant material. A middle axle plane which passes through ends which belong to the slits and are close to an axle center, and a vertical plane where the slits are arranged form an included angle gamma. The bottom of the whirlwind-type flow-smoothing gas storage chamber is connected with a whirlwind-type accelerating chamber. A low end of the whirlwind-type accelerating chamber is provided with a whirlwind-type gas flow conveying pipes. The whirlwind-type gas flow conveying pipes are arranged at both sides of a power-gas flow conveying pipe and form respectively beta angles with the power-gas flow conveying pipe. The ladle bottom blowing power injectiondevice with the whirlwind-type flow-smoothing gas storage chamber can reduce obviously a degree of powder-gas flow pulsation, accumulation of falling powder, and resistance to a powder-gas flow when the powder-gas flow is fed into the slits, can improve obviously a uniform flow conveying rate of the powder-gas flow in the slits. The ladle bottom blowing power injection device with the whirlwind-type flow-smoothing gas storage chamber has the advantages of stable blowing, small pulsation, low corrosion on fire-resistant materials, safe and reliable characteristics, feasibility for continuous and stable blowing and long service life of fire-resistant materials.

Owner:NORTHEASTERN UNIV LIAONING

Novel flavoring feeding pump

InactiveCN104214087AImprove the accuracy of useCompletely sealedRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

The invention relates to the technical field of pumps, in particular to a novel flavoring feeding pump. The novel flavoring feeding pump comprises a pump body, a base, a joint drive, internal parts and the like. According to the novel flavoring feeding pump, a design structure is innovated; the processing technology is improved; metal and non-metal combination materials are reasonably selected; and therefore the shortage of the traditional technology is overcome. It is ensured that the pump can meet working conditions with high temperature, high pressure and various kinds of viscosity, and flavoring feeding chemical media and various harsh chemical media can be efficiently conveyed. A short shaft of a self-centering structure and the magnetic or mechanical sealing mode are adopted to enable the pump to be connected with the drive of a motor; the zero-leakage non-pulse aim is truly achieved; the problem that a traditional pump is prone to leaking is solved; radial loads caused by non centering are omitted; the overload protection effect is achieved; and application of cut tobacco mixing flavoring, cut stem flavoring, cut stem feeding, leaf feeding, cut leaf feeding and moisture regaining of the tobacco industry and application of conveying, metering, circulating, injecting, lifting and the like of flavoring feeding of industries such as food, pharmacy and chemical engineering can be met.

Owner:何祥军

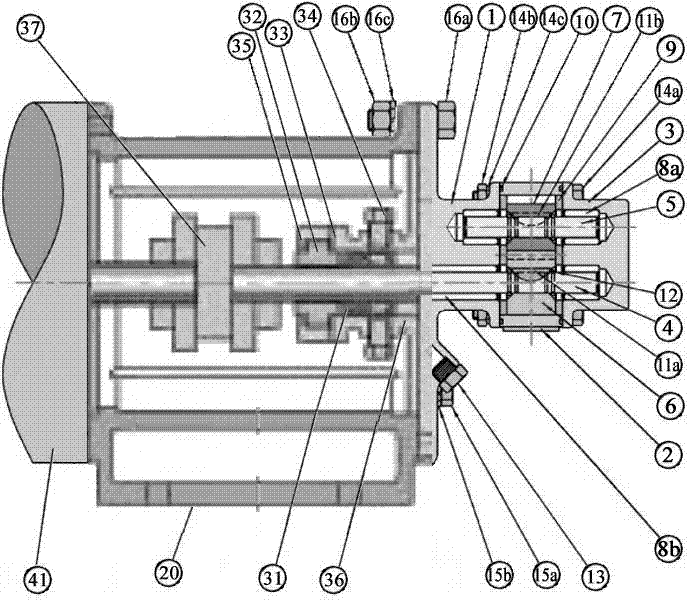

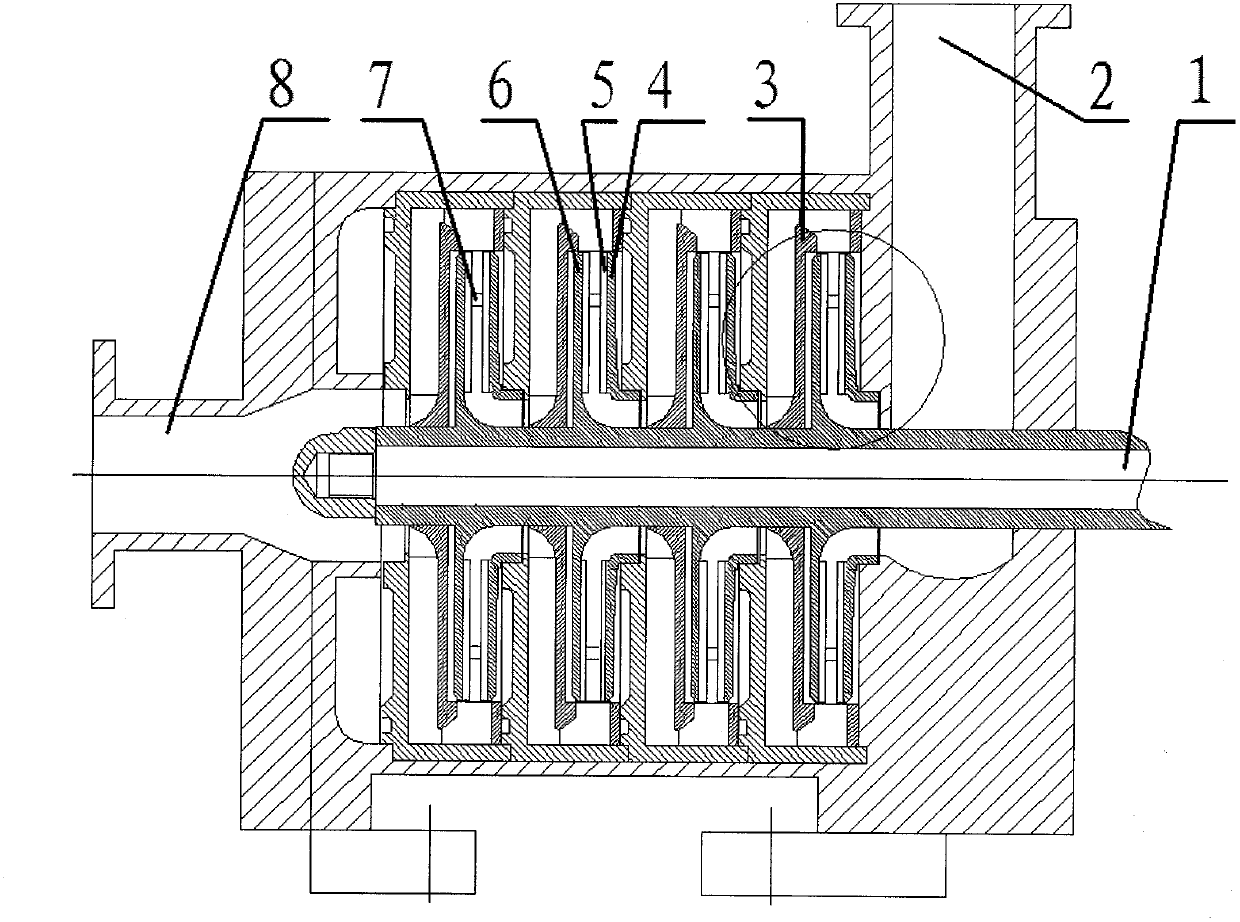

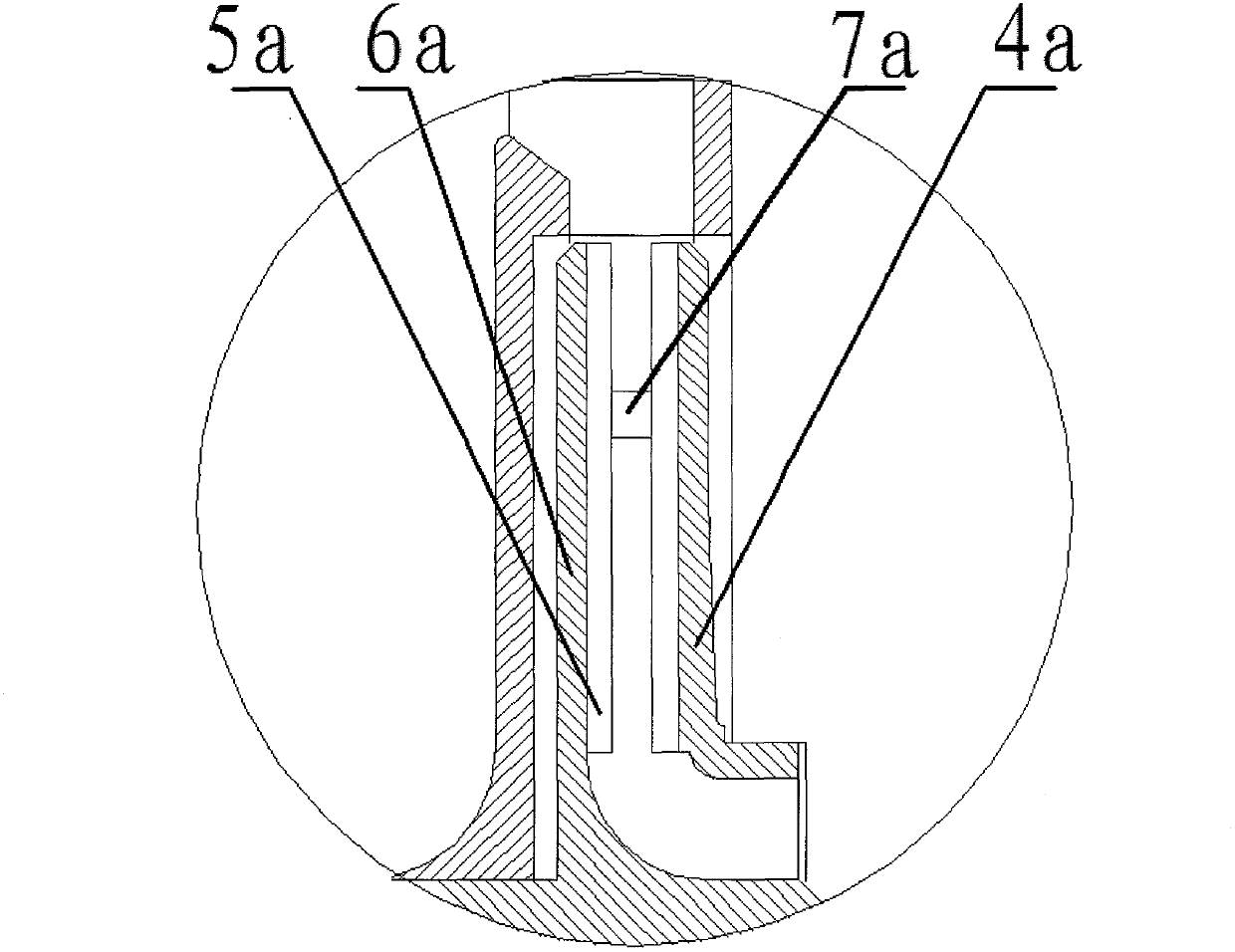

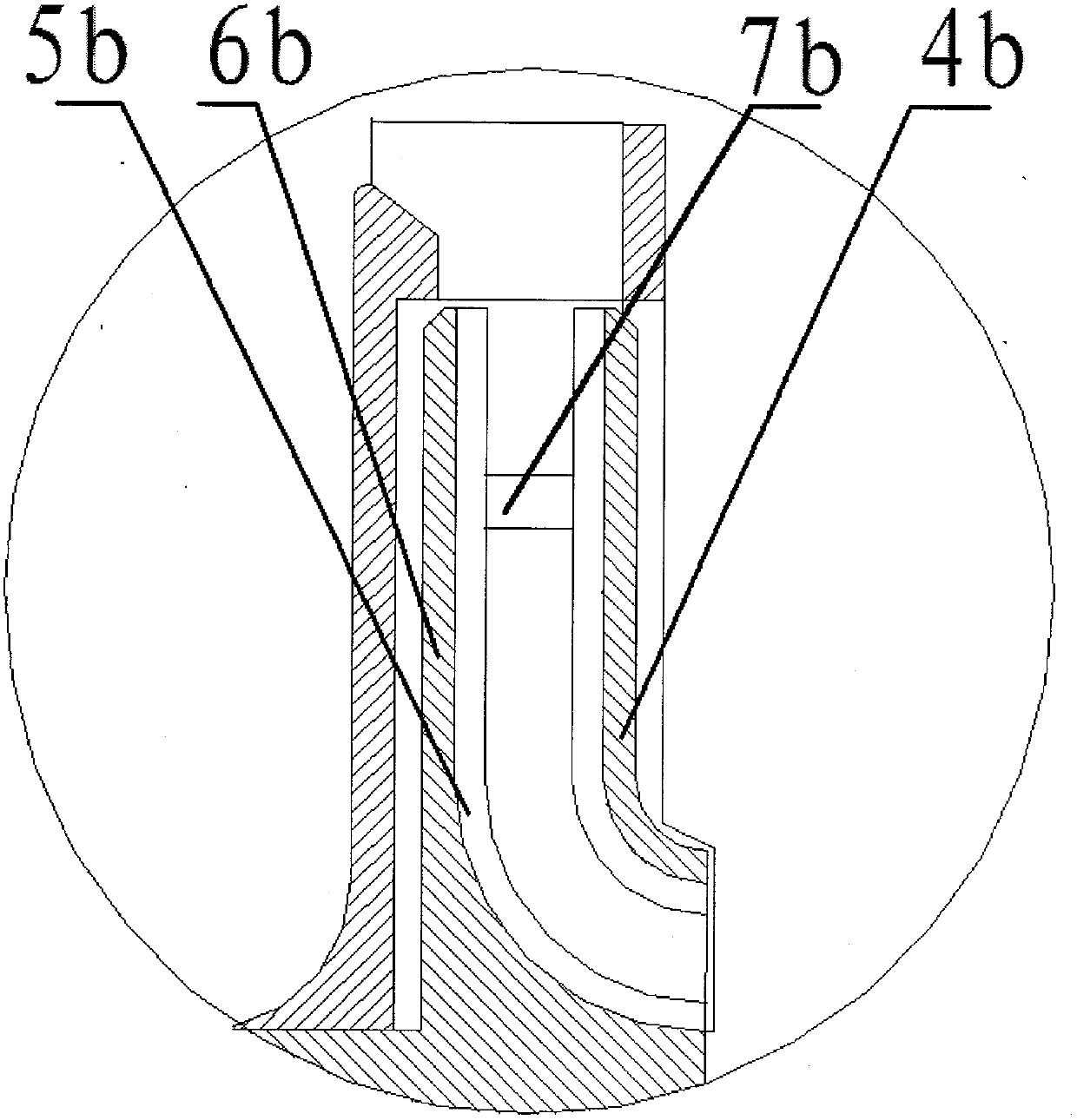

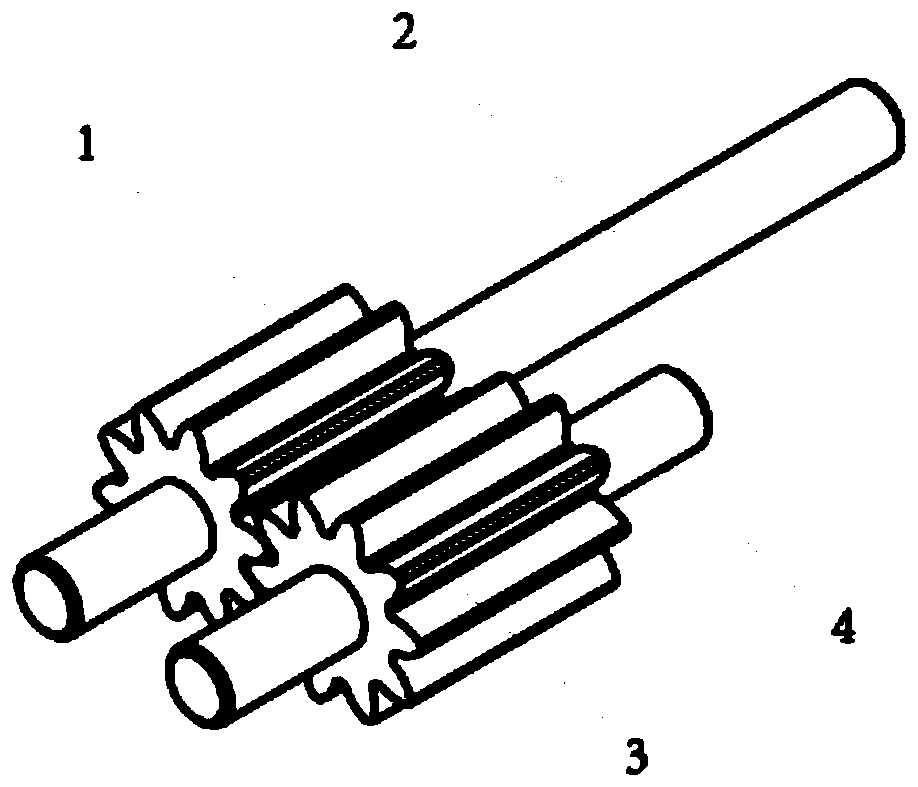

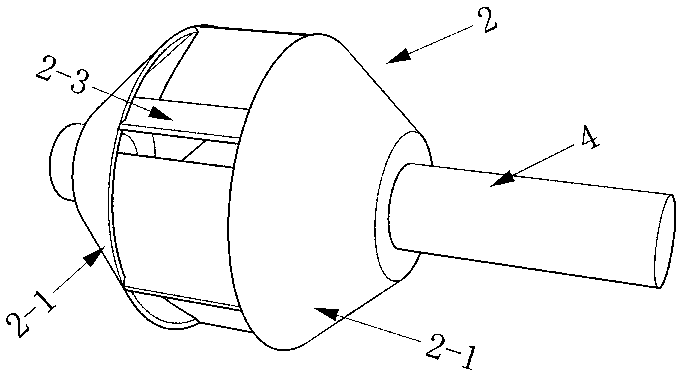

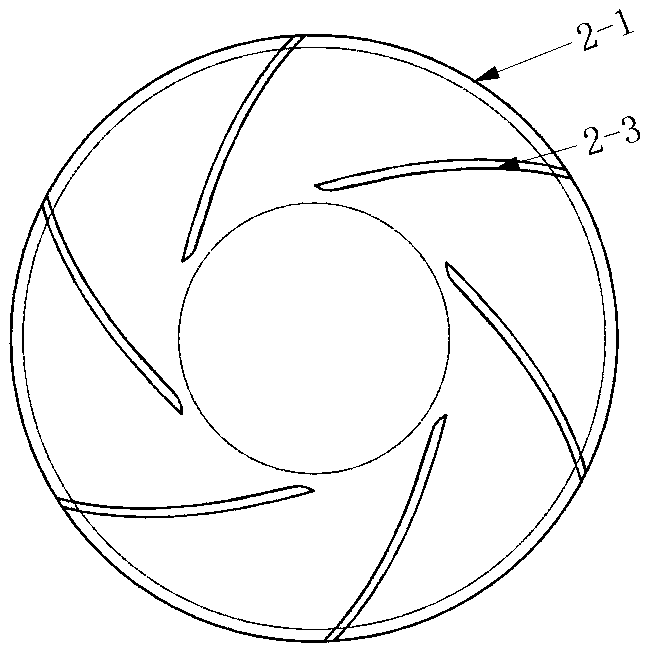

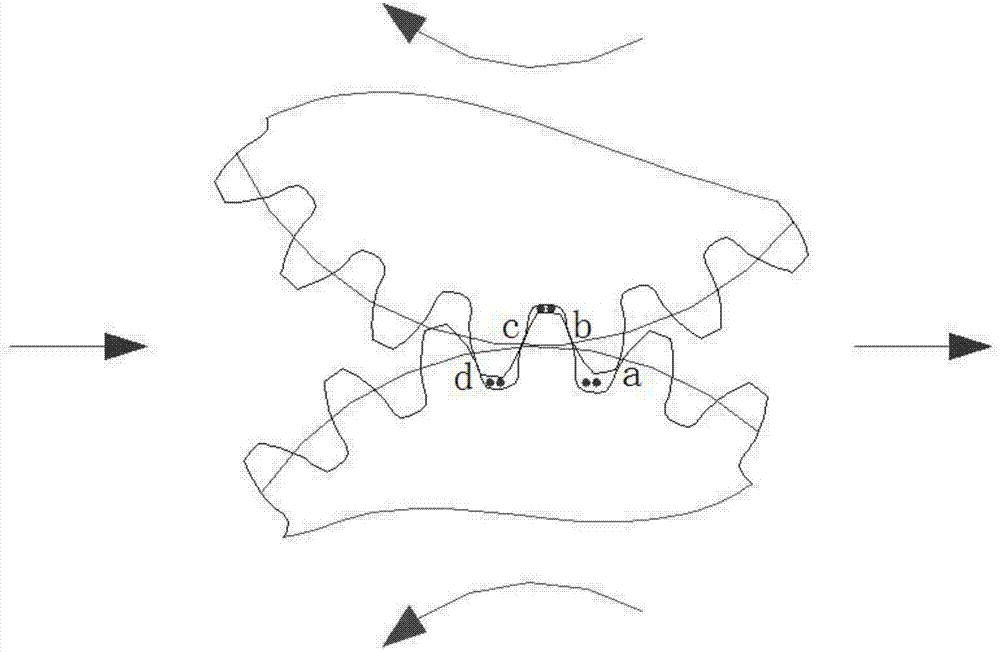

Multistage blade mud pump for riserless subsea mudlift drilling

InactiveCN103306987AFlow head curve is flatWide range of workSpecific fluid pumpsPump componentsOcean bottomImpeller

The invention discloses a multistage blade mud pump for riserless subsea mudlift drilling. The multistage blade mud pump comprises driving impeller cover plates, driven impeller cover plates, radial blades, guide vanes, a driving shaft and the like. The radial blades are arranged between the driving impeller cover plates and the driven impeller cover plates and are discontinuous, namely a bladeless area is present; the driving impeller cover plates and the driven impeller cover plates are connected through connecting arms; inlet sections of the driving impeller cover plates and the driven impeller cover plates are properly transited to the radial direction in an arc form or a conical form; and a fluid medium is guided to the next stage of impeller through a guide vane. The multistage blade mud pump can deliver multi-phase flow media, is not blocked, and is wear-resistant and high in lift; and a flow-lift performance curve is flat, a working range is wide and the requirement on mechanical sealing property is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

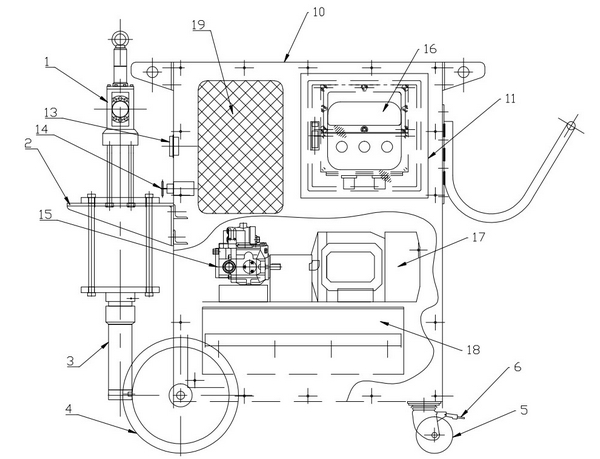

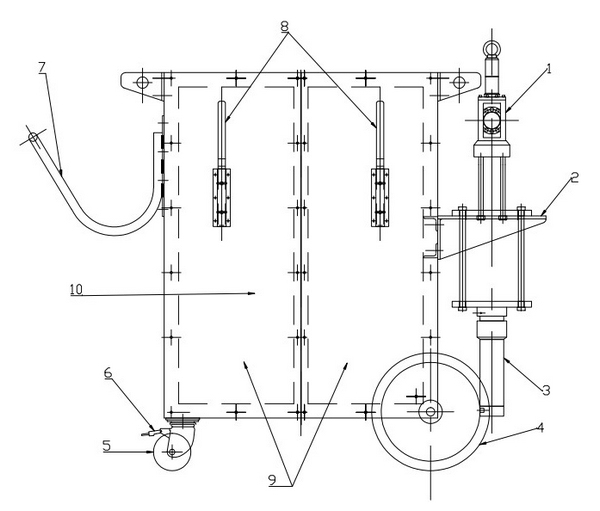

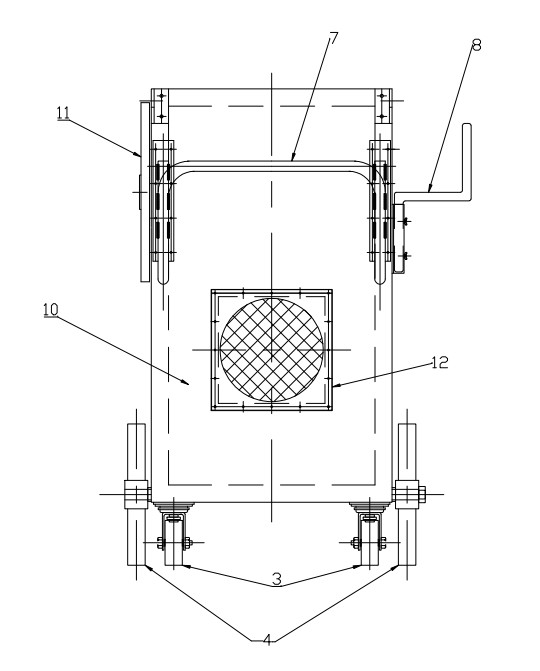

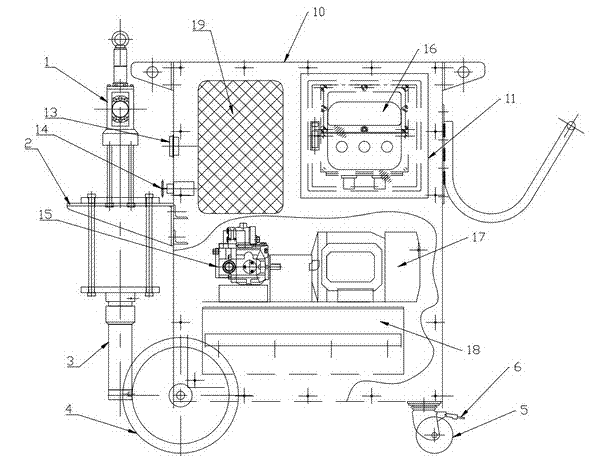

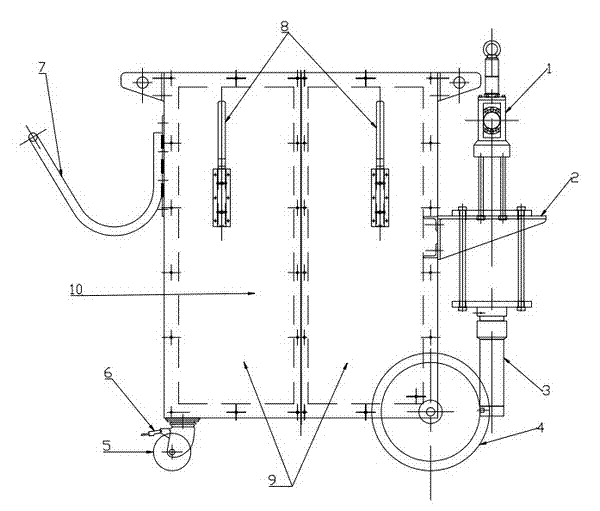

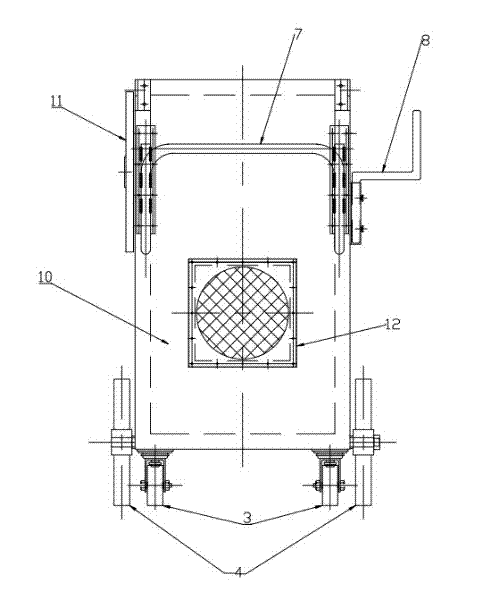

Oil pressure coating device

InactiveCN101982245AReduce working spaceImprove work efficiencyLiquid spraying apparatusUltra high pressurePower cable

The invention provides an oil pressure coating device which consists of a case, a hydraulic device, a spraying device, a moving device and two spraying guns. The oil pressure coating device is characterized in that the device further comprises a fixing table, a coating pump part, a rubber wheel, a small cartwheel, an automatic brake, a coating tube accepting region, a power cable accepting region, a piston pump, a pressure-proof and explosion-proof brake disk, an electromotor and an oil box; the device can obtain the coating power by the oil pressure and can realize the ultra-high pressure, wherein the maximum discharging pressure is 50Mpa and is larger than the air pressure type coating device with 20MPa of the discharging pressure by 30MPa; the device realizes the large capacity, wherein the maximum discharging quantity is 8.8 L / min; the device realizes that one device can use the two spraying guns simultaneously; the device is free of impulse and is changed to be the oil pressure pressure-free variation to evenly coat the film; the coating can be directly coated without diluent during hydraulic drive, the depth of the film of the device is far larger than that of the air press type coating device, and the condensed water is unavailable, so that the device can not be frozen even in winter; and the noise value is less than 85dB due to the noise-proof facilities of the sound insulation material, so that the device is free of compressed sound and can quietly work.

Owner:张秀双

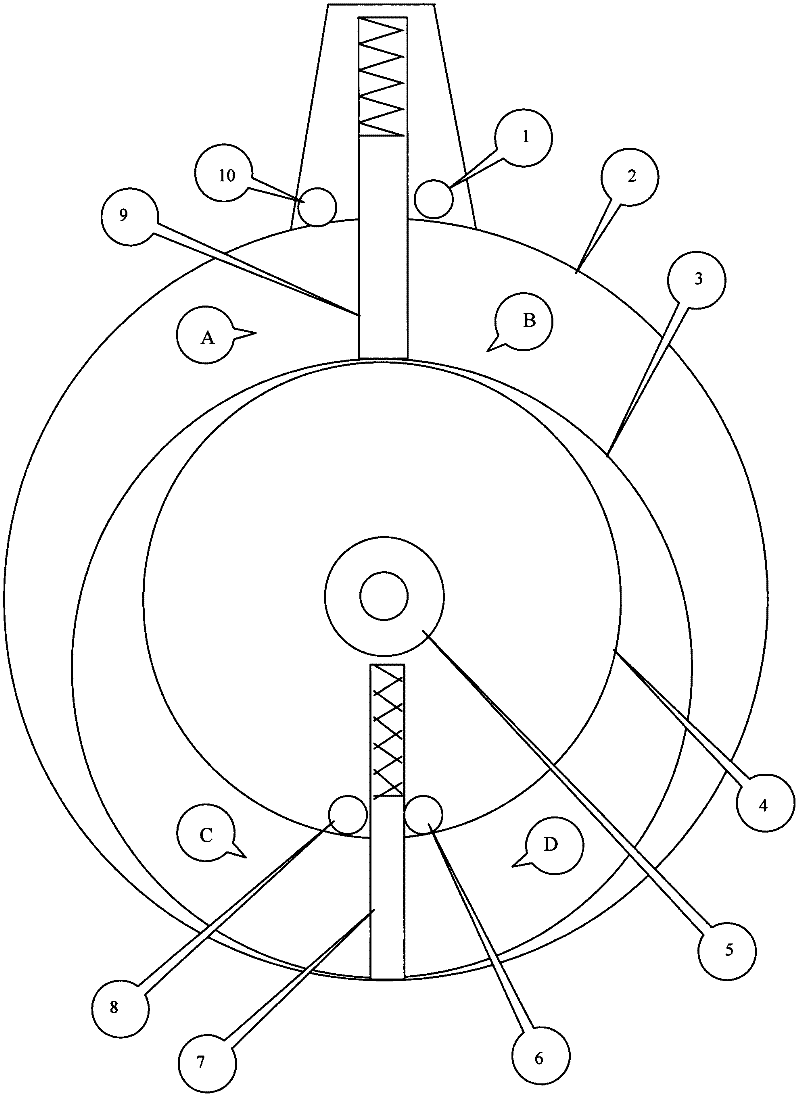

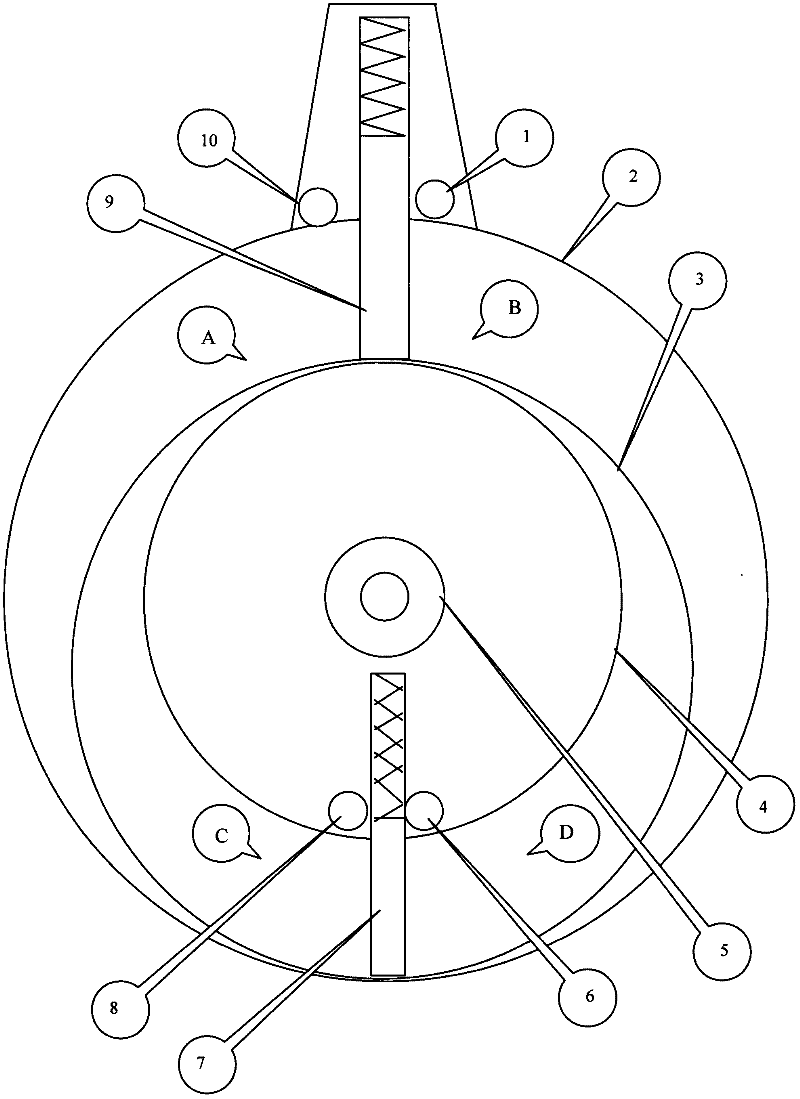

Stirling engine with eccentric shaft rolling rotation ring

InactiveCN102418621ASimple structureCompact structureHot gas positive displacement engine plantsExternal combustion engineEngineering

The invention relates to a Stirling engine with an eccentric shaft rolling rotation ring, the Stirling engine is characterized in that a cylindrical air cylinder is divided four spaces, namely two inner space and two outer through the eccentric shaft rotation ring, an inner slip sheet and an outer slip sheet, the volumes of the inner spaces and the volumes of the outer spaces periodically change, the outer paces are cold cavities, an outer shell is a radiator, the inner spaces are hot cavities, simultaneously, a heater is arranged in an inner shell, a working medium gas is high-pressure carbon dioxide, heat expansion and cold contraction of the working medium gas are respectively and simultaneously carried out in the hot cavities and the cold cavities which have periodically-changed volumes, the working medium gas is heated in the heater in the inner shell, and sequentially is subject to inflation in the hot cavity C, deflation in the hot cavity D, inflation in the cold cavity B, and deflation in the cold cavity A, and due to the pressure difference between the hot cavity C and the hot cavity D and the pressure difference between the cold cavity A and the cold cavity B, the eccentric shaft rotation ring is driven to clockwise rotate to work. Thus, in the Stirling engine, the system has a simple and compact structure; as the heat expansion and the cold contraction of the working medium gas are simultaneously carried out, and the working medium gas always flows towards the same direction, the engine has good movement stability without pulsation; compared with a piston type external combustion engine, the system heat efficiency is improved; the working medium gas adopts the high-pressure carbon dioxide which has good flowability and can absorb heat in a subcritical zone and discharge heat in a supercritical zone, so that the working medium gas has a good heat-transfer characteristic, the cost is low, and the environmental-friendly effect is achieved.

Owner:曾涛

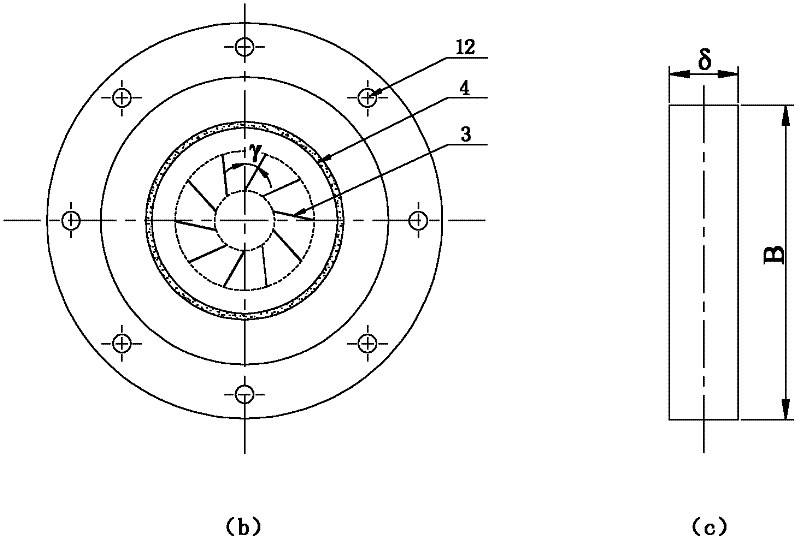

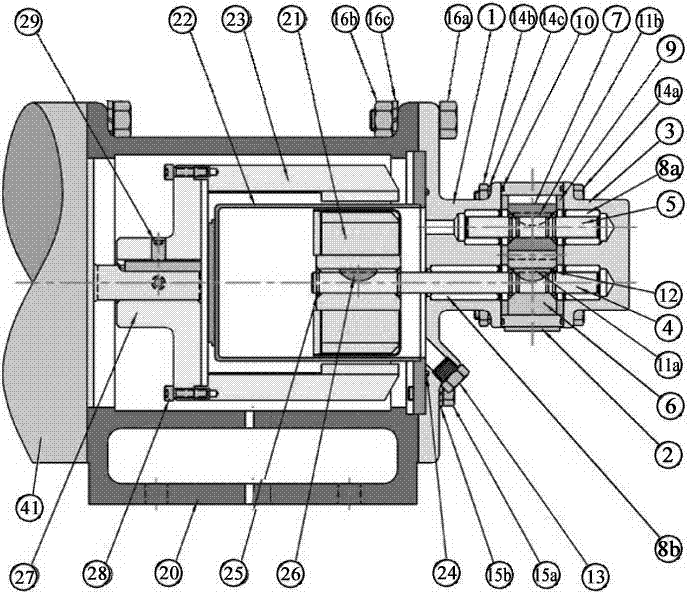

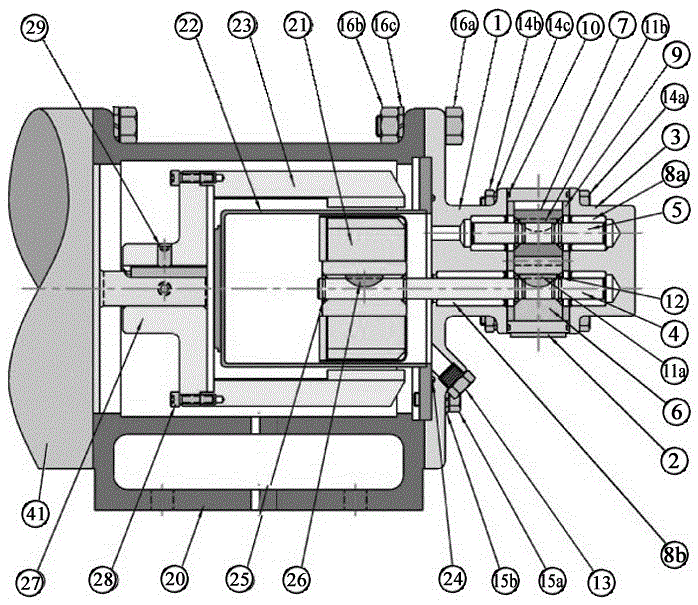

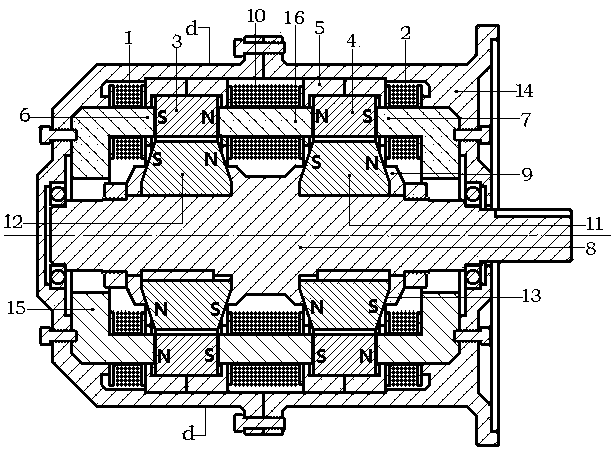

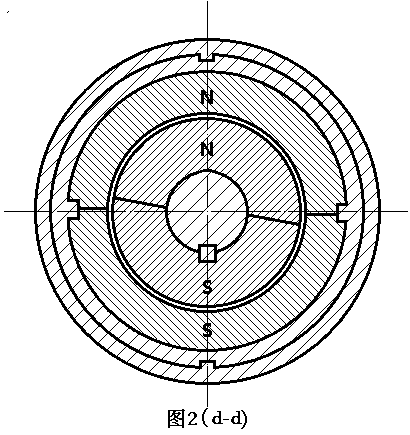

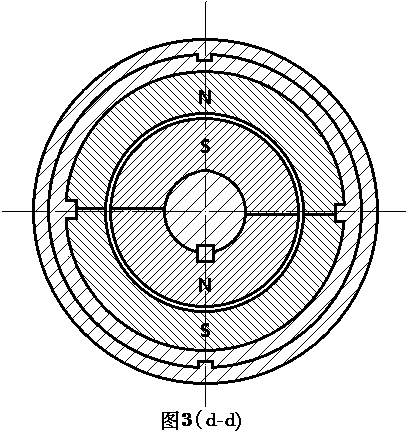

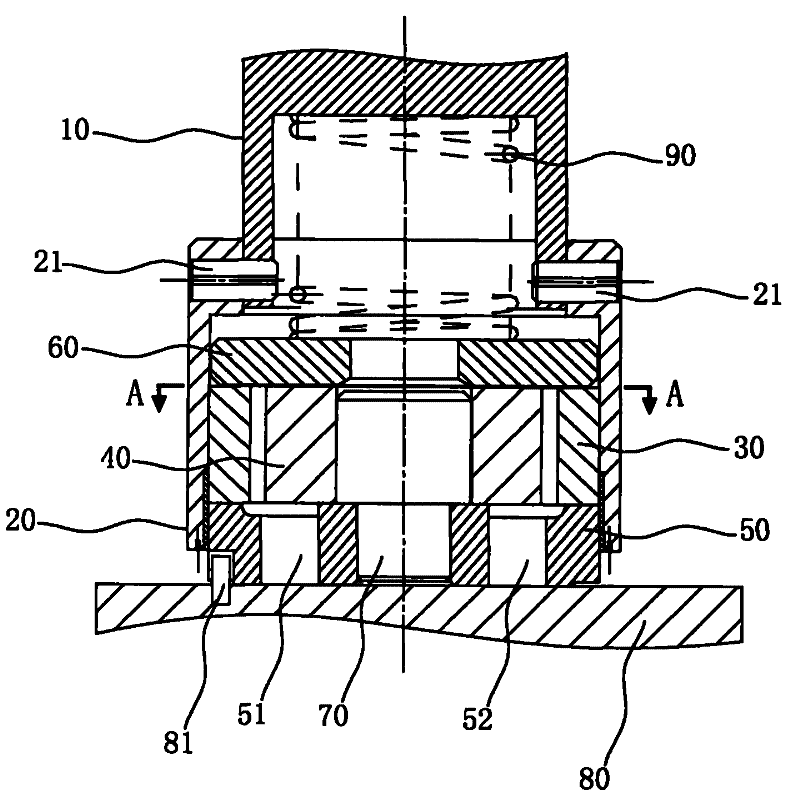

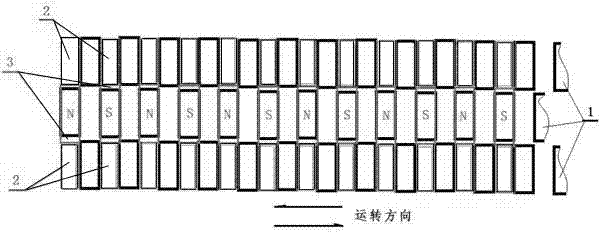

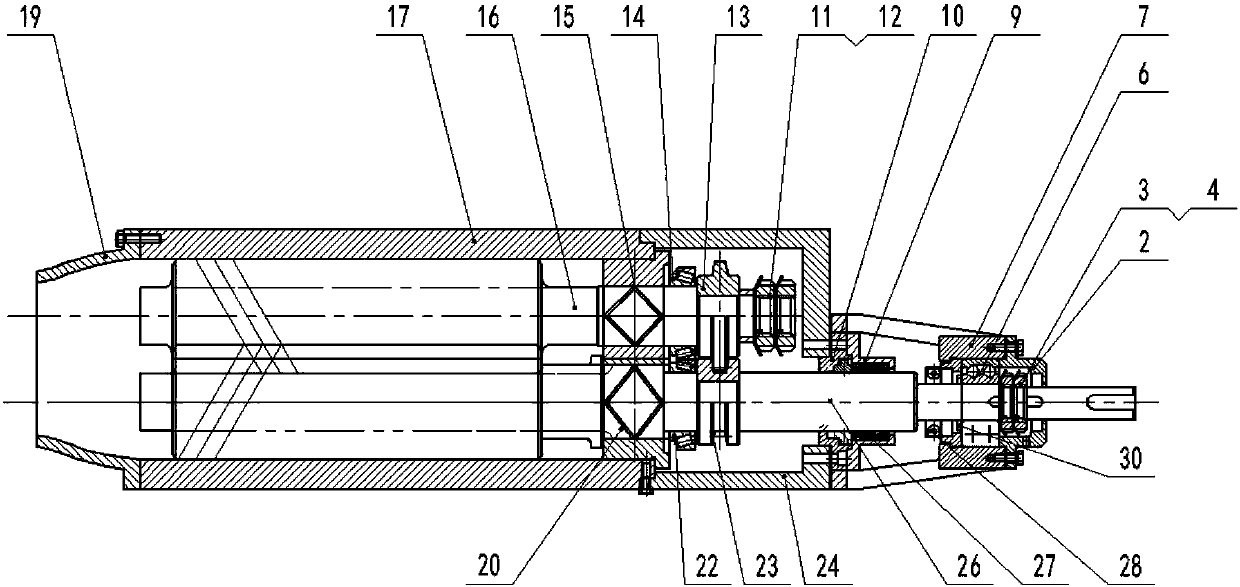

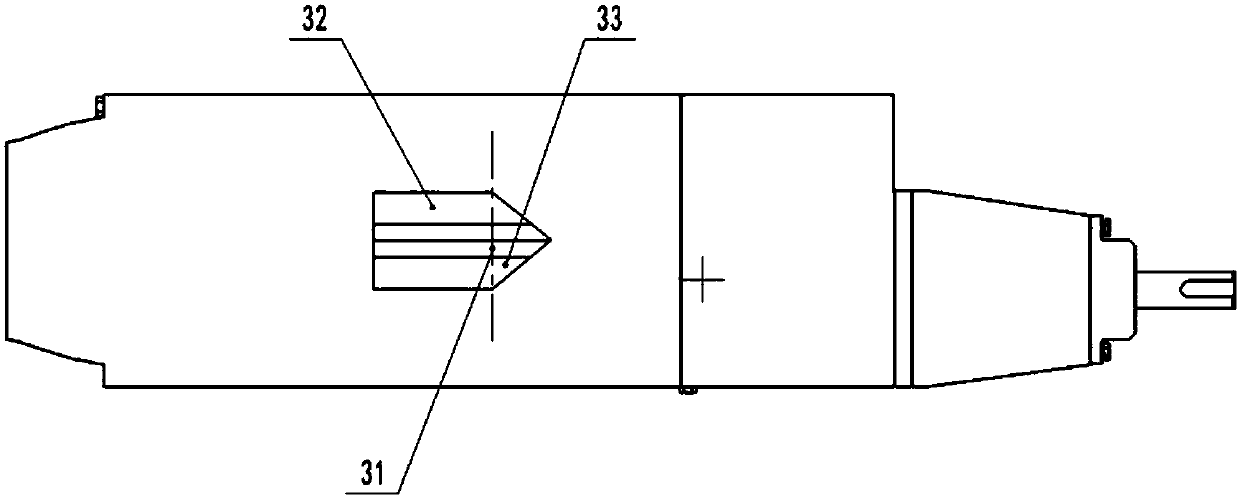

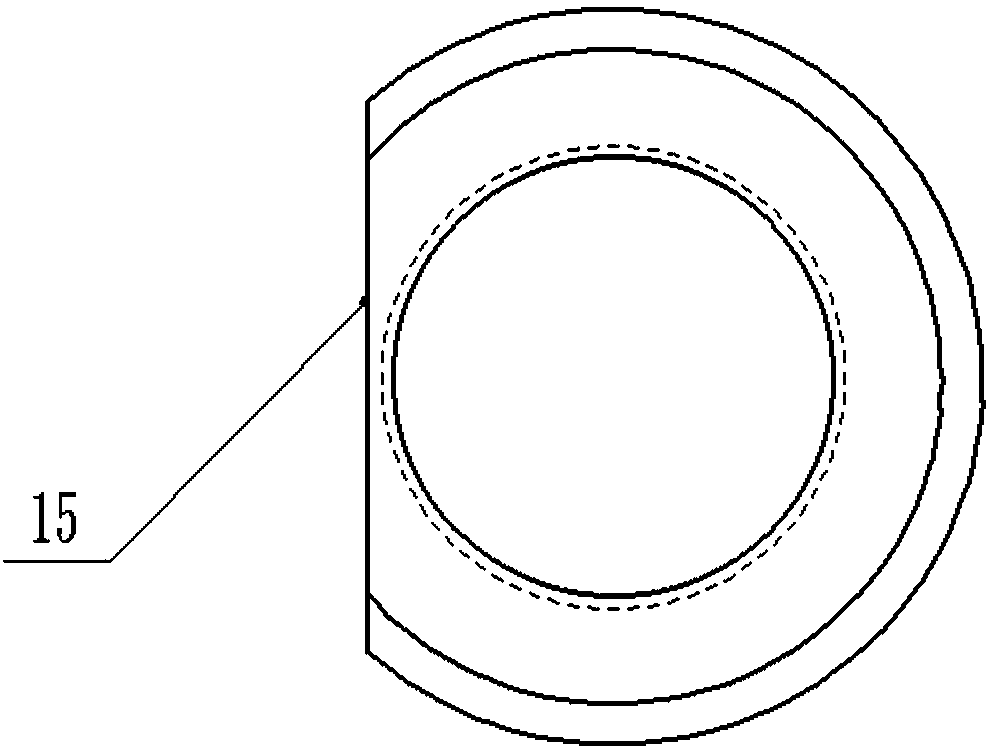

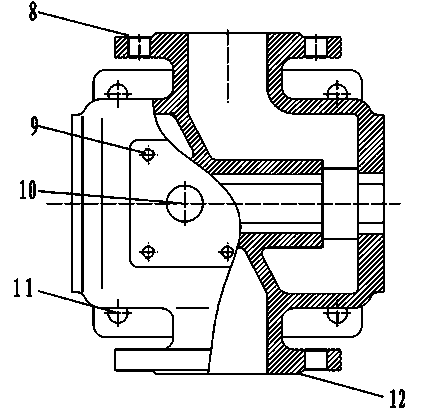

A new type of magnetic gear pump

ActiveCN104214089BEfficient deliveryImprove the accuracy of useRotary piston pumpsRotary/oscillating piston combinationsMagnetic tension forceGear pump

A new type of magnetic gear pump, the invention relates to a pump, in particular to a pump for conveying various chemical media or oil or water or toxic, harmful or flammable and explosive liquids, with corrosion resistance, acid and alkali resistance, high temperature and high pressure resistance, A new type of magnetic gear pump with zero leakage and no pulsation with magnetic drive. The magnetic gear pump provided by the present invention solves the deficiencies of the current technology by innovatively designing the structure, improving the processing technology and rationally selecting metal and non-metal composite materials, thereby ensuring that the pump can meet the working conditions of high temperature, high pressure and various viscosities. Harmful, volatile, easy to corrode, easy to crystallize and various harsh chemical media for efficient transportation; and the design uses magnetic drive to connect the drive of the pump and the motor, which truly achieves zero leakage and no pulsation, and solves the problem of existing shaft seal leakage , eliminates the radial load caused by misalignment, plays an overload protection role, and meets a wide range of applications in various industries such as petroleum, chemical, pharmaceutical, food, tobacco, paper and laboratories.

Owner:何祥军

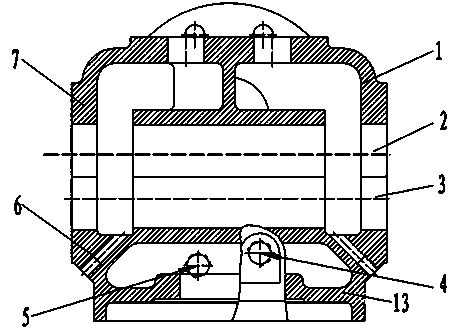

Lubricating pump

The invention belongs to lubrication technical field, concretely relates to a lubricating pump. The lubricating pump includes an internal rotor and an external rotor which are in cycloid type gear engage engagement with each other, gears of the internal rotor and the external rotor are engaged with each other for sucking and supplying oil. The lubricating pump of the present invention adopts a machine-pump integrated structure, has characteristics of built-in integration and without outer leakage, heat generated when the lubricating pump is working is brought by the lubricating fluid, so that stable and safe operation of whole system is guaranteed, the present invention reduces middle transmission link, realizes synchronous operation of the lubricating pump and lubricated mechanism or device, not only increases working efficiency of the lubricating pump, but also increases work life of the lubricating pump.

Owner:合肥华升泵阀股份有限公司

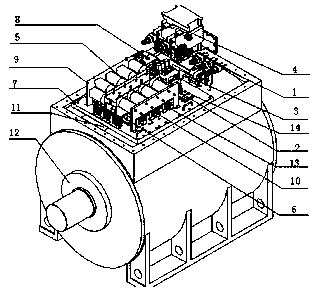

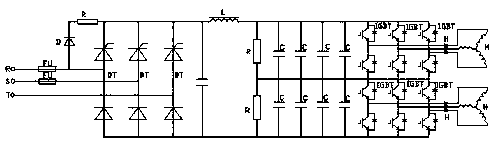

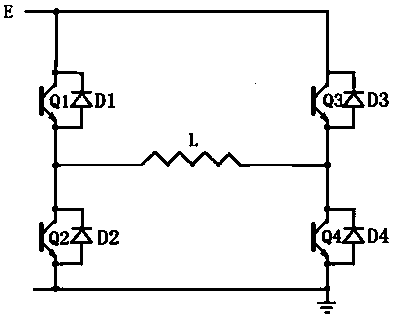

Main circuit structure of 1140V permanent magnet direct drive inverter-fed motor integrated machine

PendingCN108880278ASimplify the main loop structureReduce manufacturing costAssociation with control/drive circuitsAc-ac conversionBusbarThree-phase

The invention provides a main circuit structure of a 1140V permanent magnet direct drive inverter-fed motor integrated machine, comprising a pre-charging unit (2), a rectifying unit (3), a filtering unit (5), an inverter unit (6) and a motor unit (12). The pre-charging unit (2) is formed by connecting a common diode module and a resistor in series; the rectifying unit (3) is a three-phase half-controlled bridge rectifier; the filtering unit (5) is a voltage source type capacitor energy storage filtering; the inverter unit (6) is a multi-groups of two-level topology series structure; the motorunit is a multi-phase permanent magnet direct drive synchronous motor (12); and the above units are connected by a copper busbar or a laminated busbar. According to the main circuit structure of permanent magnet inverter-fed motor integrated machine adopted in the invention has smaller volume and simpler structure, and the part of motor is a permanent magnet direct drive synchronous motor, which has larger starting torque, better energy saving and effect of environmental protection, and superior performance.

Owner:SHANDONG OURUIAN ELECTRIC

Double-permanent magnet high-efficiency direct current power-saving motor

InactiveCN109756040AEfficient use ofImprove energy efficiencyMagnetic circuit rotating partsElectric machinesPermanent magnet rotorElectric vehicle

The invention relates to a double-permanent magnet high-efficiency direct current power-saving motor. The motor transforms the magnetic permeability relationship of a permanent magnetic field throughan electromagnetic field, forms a magnetic troque output of the common magnetic acting force of a permanent magnet stator magnetic field and the electromagnetic field on a permanent magnet rotor magnetic field, more fully and effectively utilizes the inherent magnetic energy of the permanent magnet, enables the permanent magnet motor to further improve the energy efficiency and the power-saving rate to a greater extent, has the characteristics of high specific power, high rotating speed, no pulsation, small iron loss, small noise, simple structure and the like, and can be widely applied to thefields of energy conservation and environmental protection such as electric vehicles, household appliances, unmanned aerial vehicles and the like.

Owner:罗吉伟

Universal toothed chain type stepless speed change transmission device

A universal toothed chain type stepless speed change transmission device is mainly composed of a left cone disc, a right cone disc and a transmission disc. The universal toothed chain type stepless speed change transmission device is technically characterized in that according to an existing toothed chain type stepless speed changer, radial concave teeth and radial convex teeth on a left cone disc and a right cone disc of a driving wheel and a driven wheel are changed into radial peak valley-shaped teeth; a chain pin is changed to move inside a chain pin sleeve in the axial direction; the two ends of the chain pin are designed to be two-faced inclined conical teeth in the front-back direction; during transmission, the inclined conical teeth at one end are subjected to axial thrust between the peak valley-shaped teeth of the left cone disc or the right cone disc, and the chain pin moves in the axial direction, so that the two-faced inclined conical teeth at the other end of the chain pin are inserted into the valley-shaped portions of the opposite conical disc, and a peak-insertion valley-pin mode is formed. According to the universal toothed chain type stepless speed change transmission device, pure-inclined teeth mesh transmission is achieved, the noise is low, pulsation and slipping are avoided, and the speed ratio torque is quite large.

Owner:范泽林

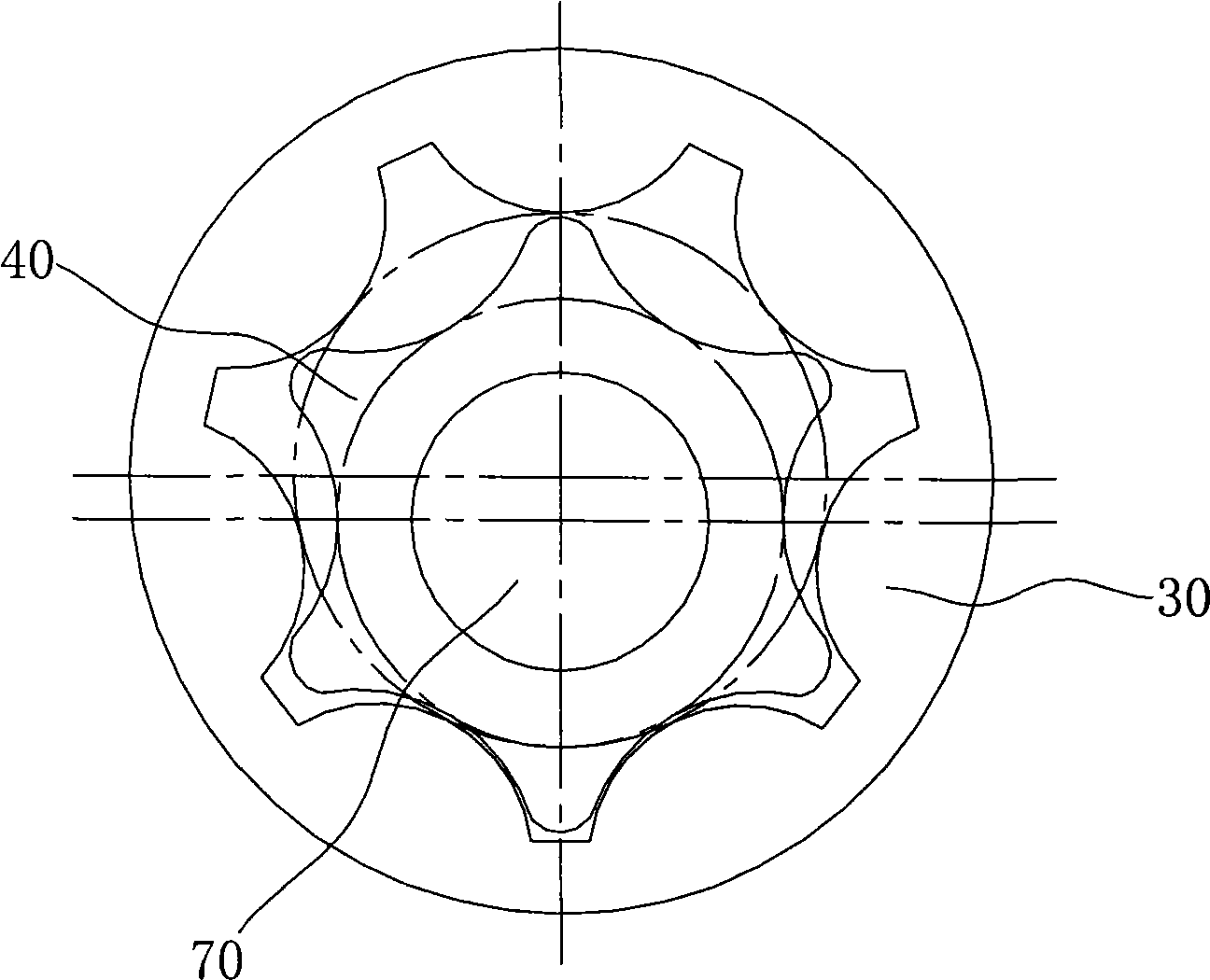

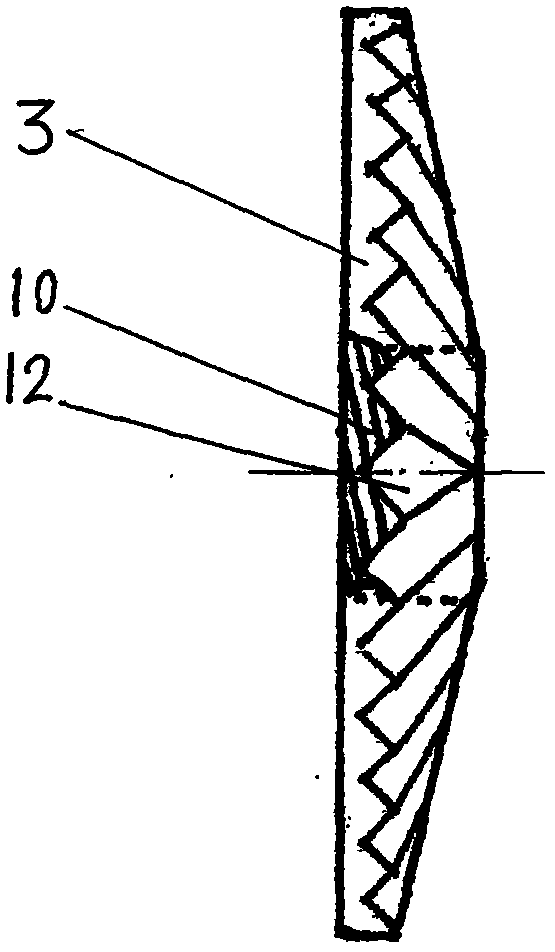

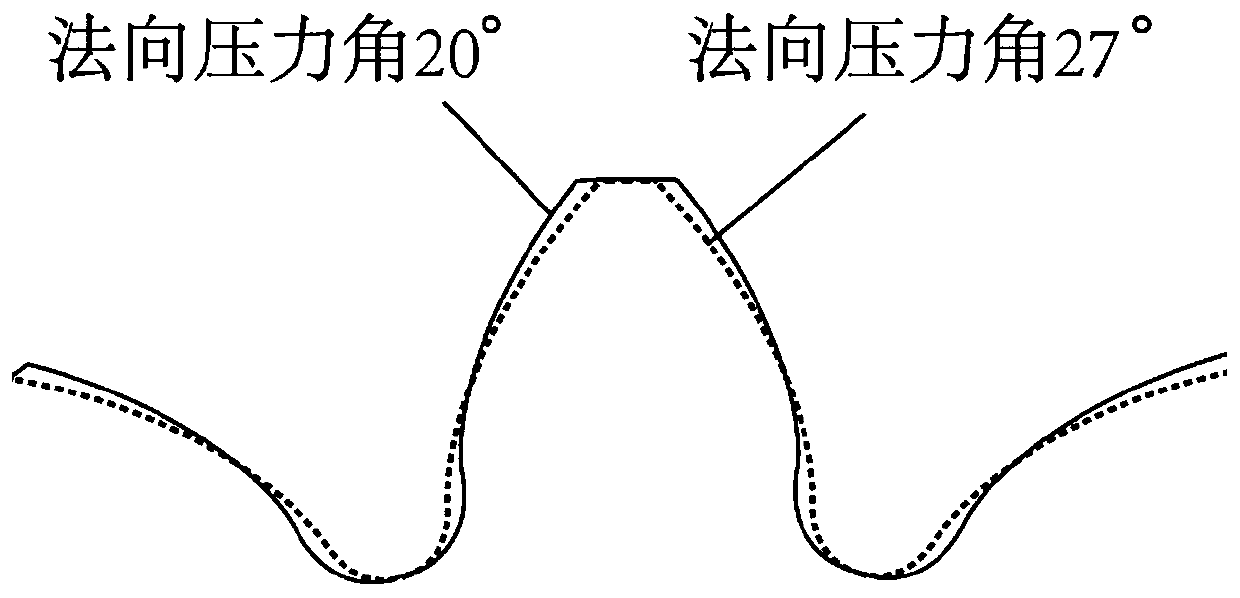

Gear pair of stable non-pulse gear pump and machining technology of gear pair die cavity

PendingCN111173735AHigh coincidenceReduce coefficient of frictionRotary piston pumpsRotary piston liquid enginesGear pumpGear wheel

The invention discloses a gear pair of a stable non-pulse gear pump and a machining technology of a gear pair die cavity. The gear pair is applied to a high-precision precise micro gear pump and comprises a drive gear and a driven gear which are engaged. The drive gear and the driven gear have the following parameters that the tooth number ranges from 10 to 18, the normal modulus ranges from 1 mnto 20 mn, the normal pressure angle is 20 degrees, the tooth top height coefficient is 0.8, the tooth root height coefficient is 1.26, the engagement angle is 29.531, and the tooth profile coincidencedegree is 1.024. Due to the fact that gear molded line parameters are further optimized, the gear coincidence degree is high after optimization, the friction coefficient is reduced, the service lifeof the gears is prolonged, and the gear pump has the beneficial effects that media conveyed out are stable, free of pulses and high in continuity; and a novel surface treatment technology is adopted for manufacturing a gear cavity, the manufacturing precision, density and saturation of the gears are improved, the gear torque is improved, friction force is reduced when the gears are engaged, meanwhile, stability and production efficiency of the product are improved, and the service life of a die is greatly prolonged.

Owner:彭延平

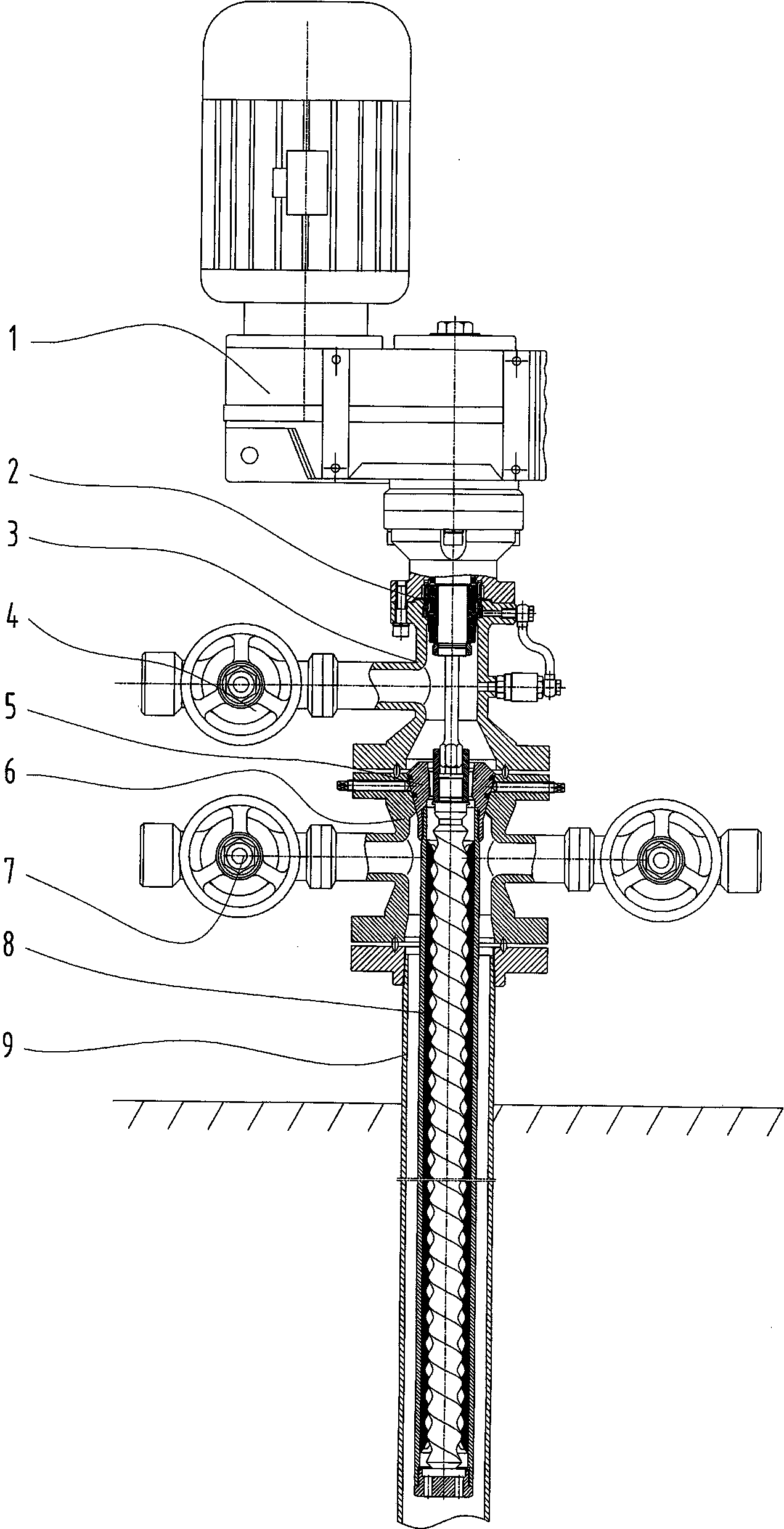

Single-screw boosting water injection pump

The invention discloses a single-screw boosting water injection pump which is characterized in that the lower part of a four-way joint is connected with the upper part of a sleeve pipe; a suspender is arranged on the upper end hole of the four-way joint; the part of contact between the suspender and the four-way joint is kept sealed; a stator of a single-screw pump is connected to the lower part of the suspender and arranged in the sleeve pipe; a sleeve pipe valve is mounted on the side opening of the four-way joint; a tee joint is mounted on the upper end surface of the four-way joint; a water inlet valve is mounted on the side opening of the tee joint; a mechanical seal device is mounted in the upper part of the tee joint; a rotary power device is mounted at the upper end of the tee joint; a central shaft of the rotary power device penetrates through the mechanical seal device to be connected with a rotor of the single-screw pump and can drive the rotor of the single-screw pump to rotate. The single-screw boosting water injection pump is stable in running, free of pulsation, low in fault rate, reliable to seal and long in service life; the water injection amount can be increased and the water injection cycle can be prolonged; the single-screw boosting water injection pump is mounted in a well with boosting water injection requirements, does not take up ground space and has remarkable economic benefits.

Owner:张成功

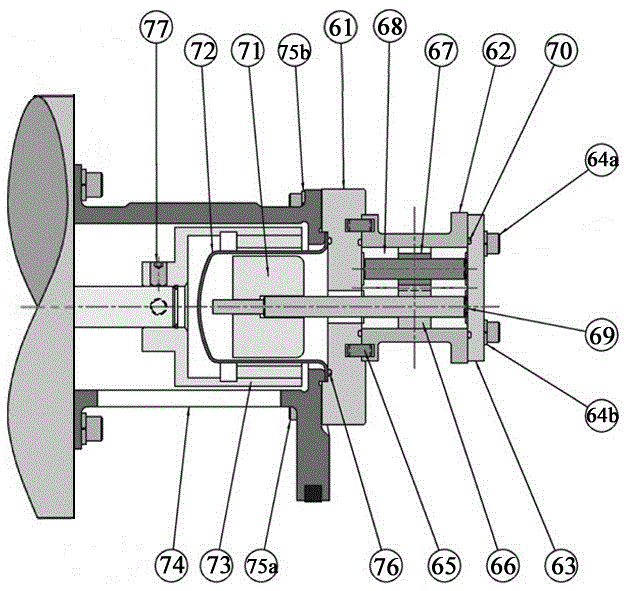

Cantilever type double-screw water-jet propulsion pump

InactiveCN106014975ANo stirringNo pulseMachines/enginesRotary/oscillating piston pump componentsLow noiseWater flow

The invention discloses a cantilever type double-screw water-jet propulsion pump. Besides the components of a common double-screw pump, the cantilever type double-screw water-jet propulsion pump comprises a water inlet, a double-bearing structure for balancing an axial force and a radial force, a double-screw structure and a jet nozzle, wherein a tooth type curve of the double-screw structure is an involute. According to the cantilever type double-screw water-jet propulsion pump, screws are rotated to push water flow, and a carrier in water is pushed forward by a reaction force of high-speed water flow jetted from the cantilever type double-screw water-jet propulsion pump. A cantilever type structure is simple and efficient, and can reduce hydraulic loss fully and generate sufficient thrust to improve the propulsion capability of the carrier in water. The double-screw structure has the characteristics of no stir, no pulsation, smooth output of various media, small mechanical vibration, low noise and the like. Since a pump body structure ensures that a pumping liquid always exists as a sealing liquid in a working element of the pump, the cantilever type double-screw water-jet propulsion pump has high self-suction capacity and is commonly used for multi-phase mixed transportation. For example, the cantilever type double-screw water-jet propulsion pump can be used for transporting oils, water, paste, milk-like substances, pitch and other chemical media.

Owner:JIANGSU UNIV

Centrifugal variable-capacity type compressed gas compressor and method

InactiveCN108869334ASimple structureLow costPump componentsRadial flow pumpsMechanical wearEngineering

The invention discloses a centrifugal variable-capacity type compressed gas compressor. The centrifugal variable-capacity type compressed gas compressor comprises a machine shell and a compressed disk. The centrifugal variable-capacity type compressed gas compressor is characterized in that a cavity of the machine shell is in a barrel-shaped structure; shaft holes are formed in the middle positions of two ends of the machine shell, a vent hole is formed in the side body of the machine shell; opposite buckle type disk-shaped disk covers are arranged on two sides of the compressed disk, embankment-shaped blades are arranged between the two disk covers, a hollow shaft and a power shaft are correspondingly arranged on the two sides of the two disk covers; and the disk compressed disk is installed in the machine shell; and the power shaft is connected with a power source. The compressor has a high rotational speed, large flow, no pulse, simple structure, precious few part used, low cost anda long service life, and is capable of continuous air exhaust, is not prone losing, at the same time the compressor has the advantages that the noise is low, the compressor is very smooth, and the mechanical wear is very low.

Owner:张伟

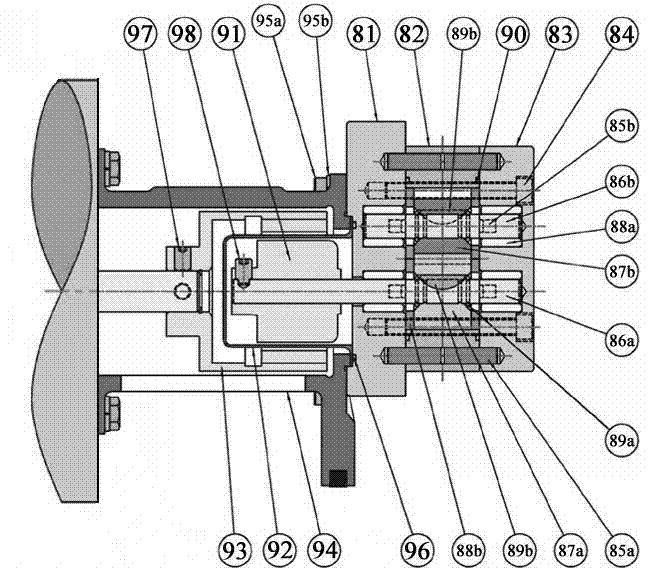

Device for separating peripheral blood mononuclear cells

ActiveCN102286360BNo pulseImprove controllabilityBioreactor/fermenter combinationsBiological substance pretreatmentsPeripheral blood mononuclear cellEngineering

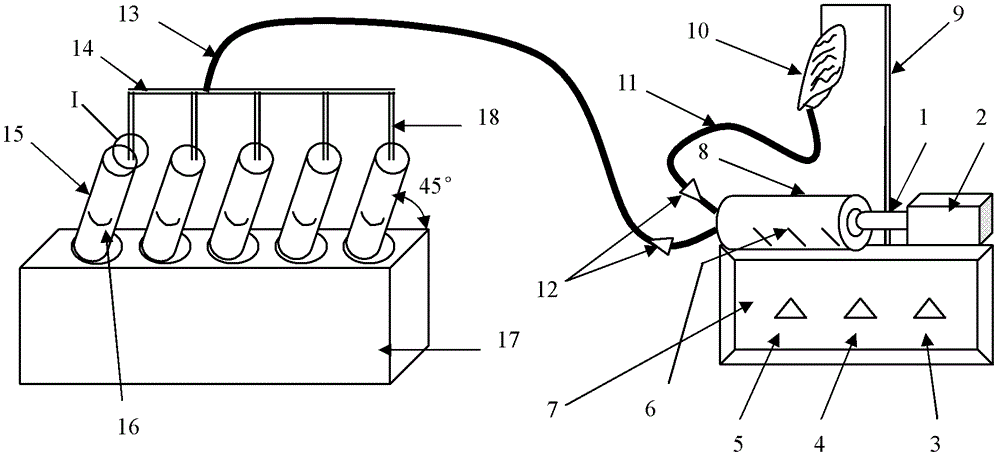

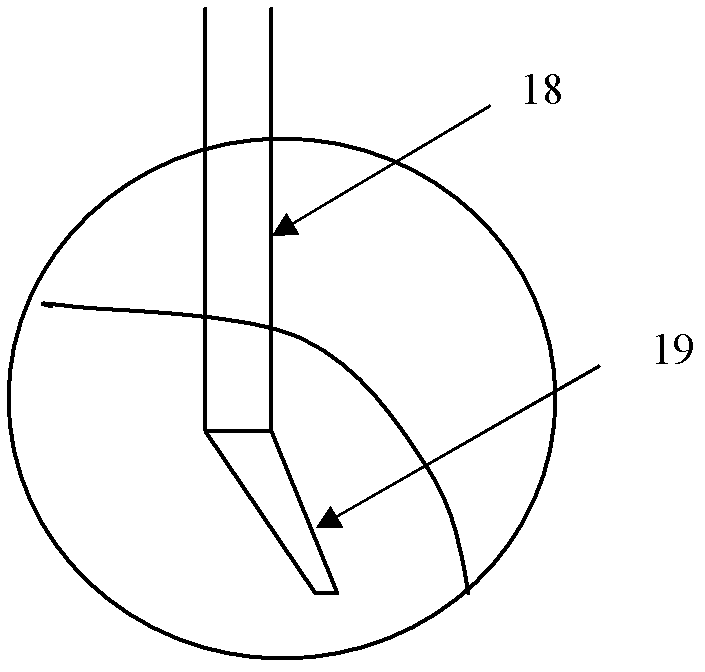

The invention discloses a device for separating peripheral blood mononuclear cells, which comprises a test tube rack and a control box, wherein a cantilever for suspending a blood bag, an injection pump and a transparent container with scales are arranged above the control box; a piston and a piston rod are arranged in the transparent container; one end of the piston rod, which penetrates out of the transparent container, is connected with the injection pump; the other end is provided with two connecting ducts which are respectively connected with the blood bag and a diversion tube; the two connecting ducts are respectively provided with a one-way valve; a control box built-in power source and a controller are connected with the injection pump; the injection pump pulls the piston rod through a tumbler switch on the control box panel so as to extract blood into the transparent container, or pushes the piston rod to extrude the blood in the transparent container; the test tube rack is provided with at least one row of test tube plug holes, into which a plurality of test tubes are inserted in a 45-degree inclined mode; the diversion tube is arranged above the 45-degree inclined test tubes, and extends a dropping tube for each test tube hole; and each dropping tube is provided with a control valve.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Lubricating pump

The invention belongs to lubrication technical field, concretely relates to a lubricating pump. The lubricating pump includes an internal rotor and an external rotor which are in cycloid type gear engage engagement with each other, gears of the internal rotor and the external rotor are engaged with each other for sucking and supplying oil. The lubricating pump of the present invention adopts a machine-pump integrated structure, has characteristics of built-in integration and without outer leakage, heat generated when the lubricating pump is working is brought by the lubricating fluid, so thatstable and safe operation of whole system is guaranteed, the present invention reduces middle transmission link, realizes synchronous operation of the lubricating pump and lubricated mechanism or device, not only increases working efficiency of the lubricating pump, but also increases work life of the lubricating pump.

Owner:合肥华升泵阀股份有限公司

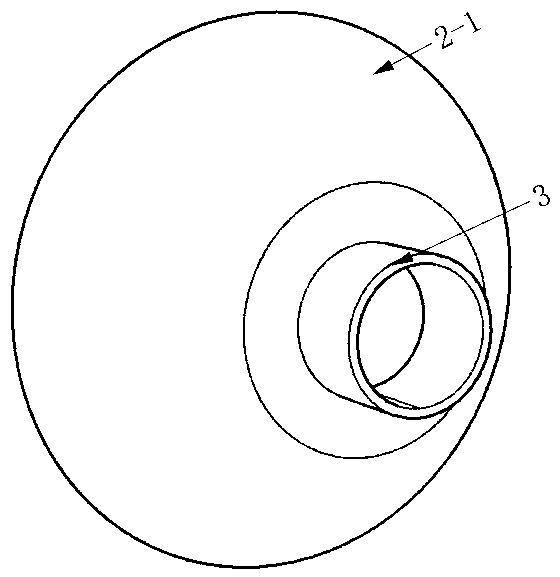

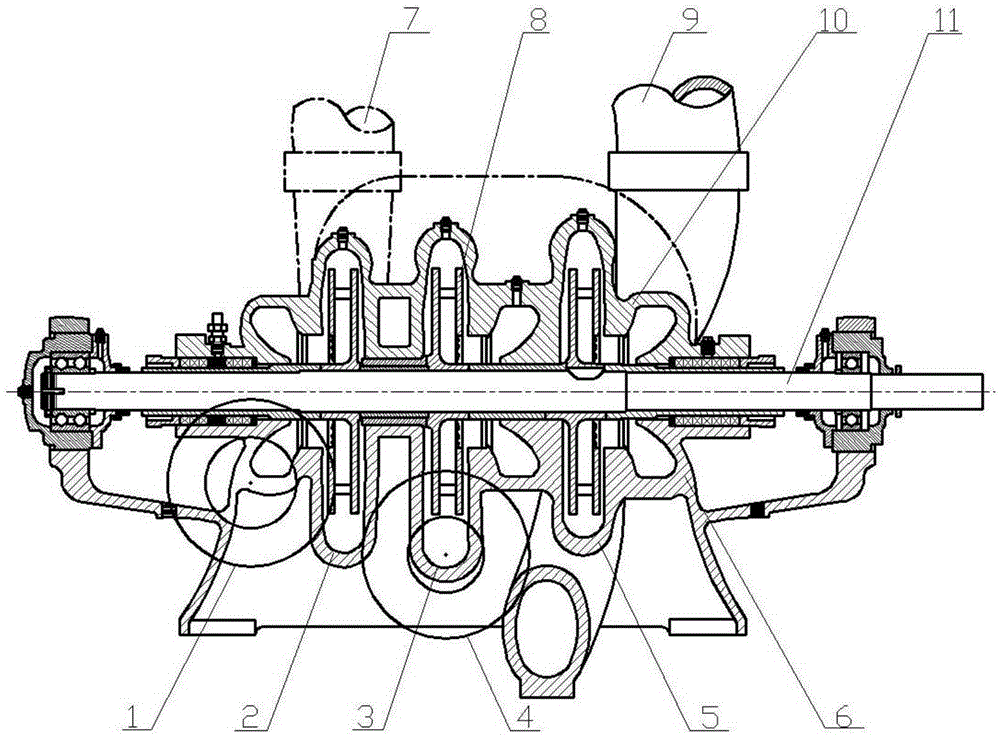

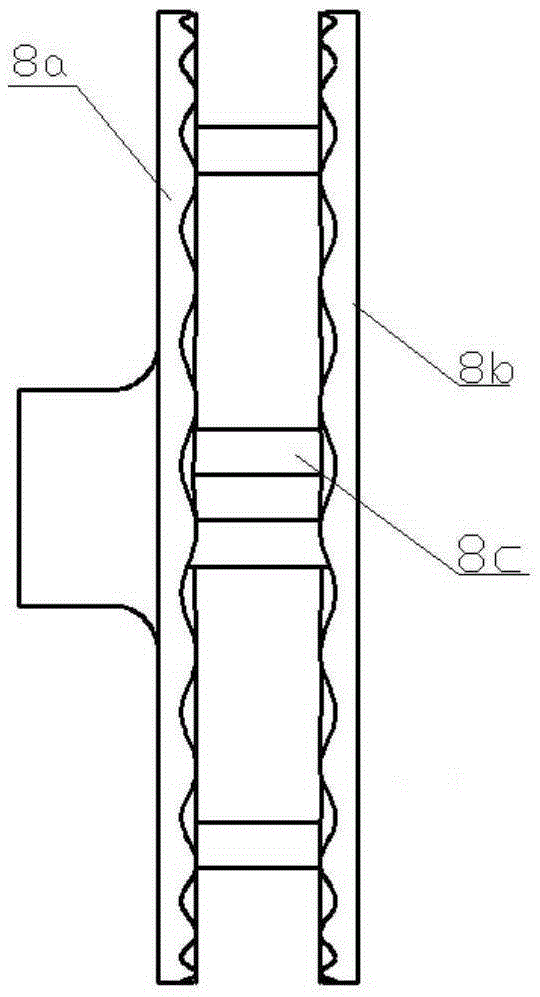

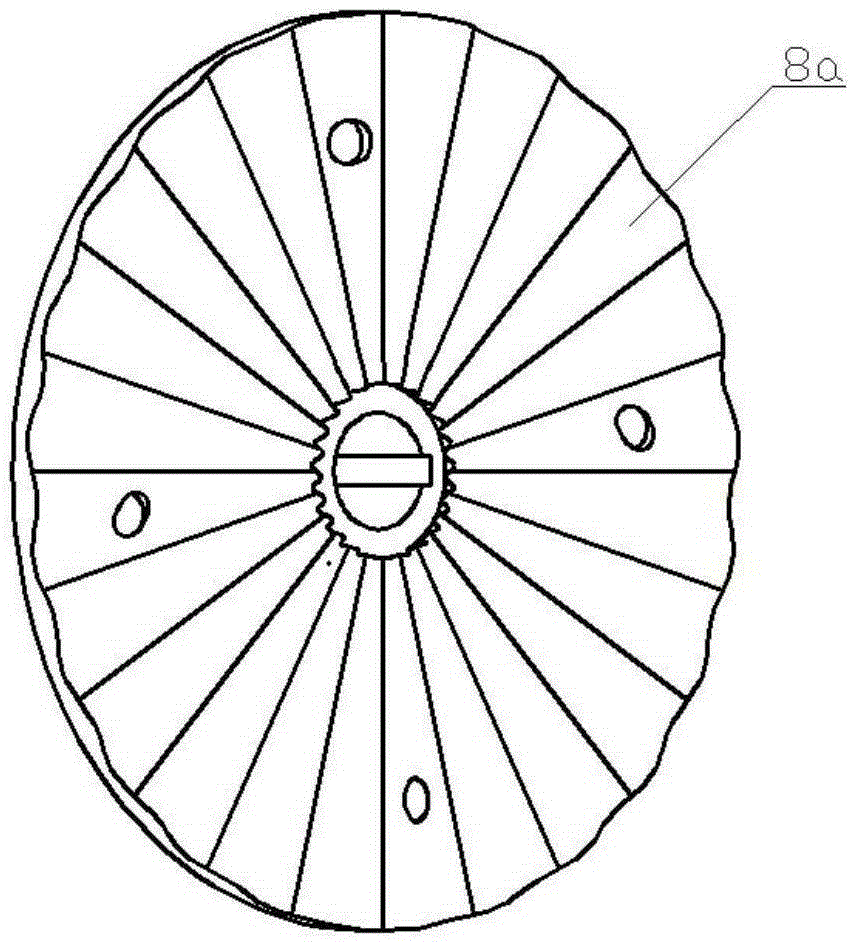

A horizontal split multistage pump capable of transporting multiphase flow media

ActiveCN102606483BFlow head curve is flatWide range of workPump componentsRadial flow pumpsImpellerHigh concentration

A horizontal central-open multistage pump capable of conveying multiphase flow media comprises a pump body, a pump cover, a pump spindle, a transition runner composed of a pump body and a pump cover, a water suction chamber, an impeller of a special structure and the like. No real blade is arranged between a driving impeller cover plate and a driven impeller cover plate, waves of special types are peripherally processed to be positioned between the driving impeller cover plate and the driven impeller cover plate, the waves are sine waves or cosine waves, and the driving impeller cover plate and the driven impeller cover plate are connected through connection arms. The horizontal central-open multistage pump is applied to long distance transporting multiphase flow medium places containing high viscosity media, media carrying a lot of gas, media containing high concentration solid phase particles, and media sensitive to shear force and the like and has the advantages of being anti-cavitation, abrasion-resistant, efficient, reliable, convenient to dismount, small in loss of water power, little in installation error and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

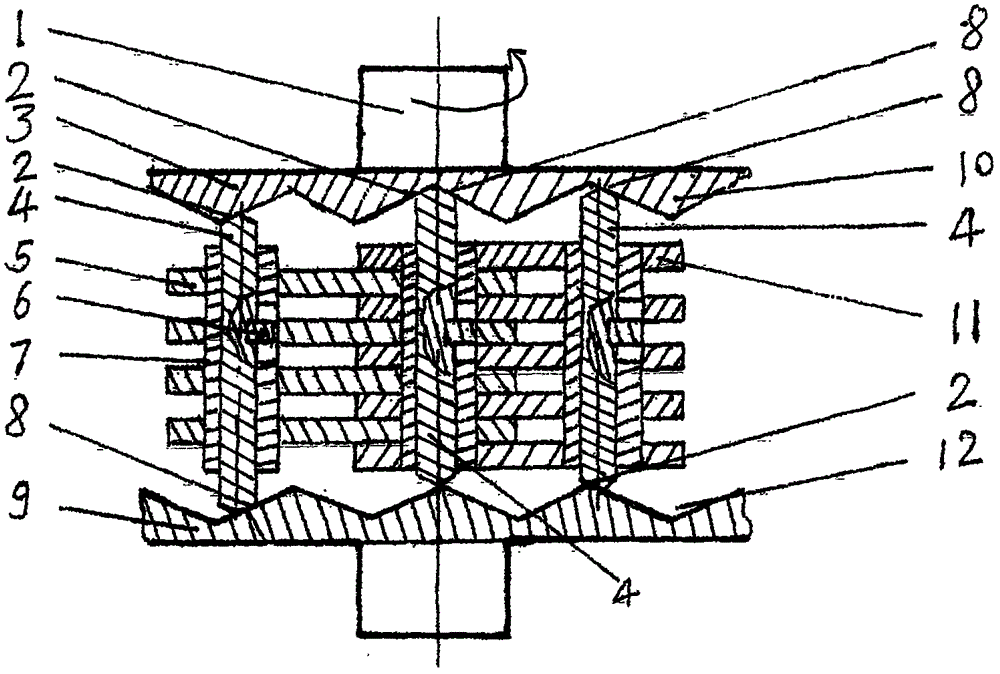

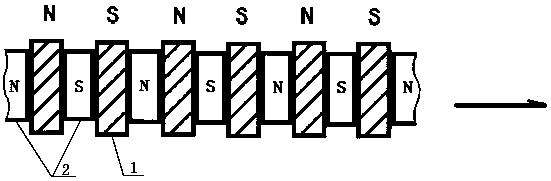

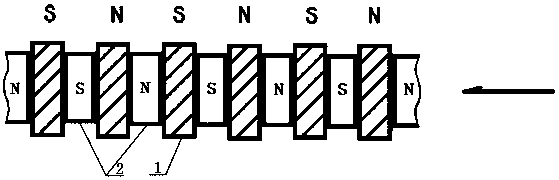

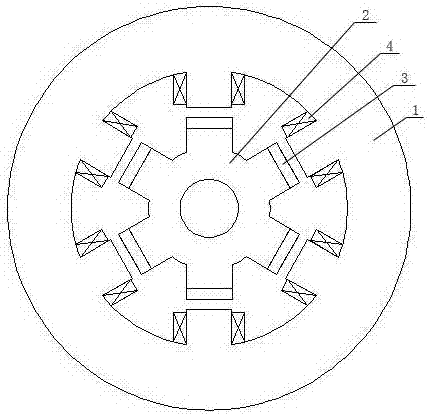

A permanent magnet single-phase switched reluctance motor and its control method

ActiveCN105634231BImprove power densityReduce inputAc-dc conversionDynamo-electric machinesElectric machineControl system

The invention discloses a permanent magnetism type single-phase switched reluctance motor. The permanent magnetism type single-phase switched reluctance motor comprise a motor output shaft, a control system and at least one set of armature device; the armature device comprises a stator and a rotor; air gaps are located between the salient poles of the stator and the rotor; the rotor fixedly sleeves the outer periphery of a motor output shaft; the number of the salient poles on the stator is consistent with the number of the salient poles on the rotor; stator electromagnetic windings are installed at the salient poles of the stator; the winding directions of adjacent stator electromagnetic windings are different; permanent magnets are embedded in the salient poles of the rotor; the magnetizing direction of the permanent magnets is radial; and the polarities of the permanent magnets embedded in adjacent salient poles of the rotor are different. The permanent magnetism type single-phase switched reluctance motor of the invention has the advantages of a conventional switched reluctance motor, and can eliminate the torque ripples of the conventional switched reluctance motor, realize bidirectional operation and improve the conversion efficiency of power source input energy. The power density of the motor can be improved. With the motor of the invention adopted, the purpose of energy conservation can be realized effectively.

Owner:上海鼎特电器有限公司 +1

Oil pressure coating device

InactiveCN101982245BReduce working spaceImprove work efficiencyLiquid spraying apparatusLow noiseFuel tank

The invention provides an oil pressure coating device belonging to the spray paint industry device field. An upper part of a main machine box door has a power cable acceptation area. A hydraulic device is arranged at the lower part in the main machine box and has an oil box. A motor and a piston pump are fixed on the oil box and connected to the oil box. An air entry and an observation window are mounted on the top of the front face in the main machine. A pressure-resistant anti-explosion type brake disc is mounted after the observation window. A fixing table is arranged at a middle part of the left of the main machine for fixing an oil pressure cylinder of the coating device and a coating pump part. A coating hose housing area is mounted at the right of the main machine. A vent is mounted on the main machine under the coating hose housing area. A movable device at the bottom of the main machine includes a small wheel, an automatic barker and a rubber wheel. The oil pressure coating device can realize the simultaneous work of one machine and two sprayers, reduce work field, improve the work efficient, shorten construction period and saves the electricity by 39%, work at a high pressure with superior stability, ensure the uniform coating, have high efficiency, lower noise and dust storm without using diluent or pulsation, and can not cause the vibration barrier such as acknowledged joint hurt and neurodynia.

Owner:张秀双

Single-phase permanent magnet type switched reluctance motor and control method thereof

ActiveCN106972725AEliminate torque rippleImprove power densityAC motor controlMagnetic circuit rotating partsElectric machineClassical mechanics

The invention discloses a single-phase permanent magnet type switched reluctance motor which comprises a stator and a rotor. The stator is formed by front, middle and back sections of stator cores, the numbers of the salient poles of the three sections of stator cores are the same, and gaps are arranged between the three sections of stator cores. The salient pole center lines in the front and back sections of stator cores are in a same straight line. A salient pole center line in the middle section stator core and the concave pole center lines in the front and back sections of cores are overlapped. The salient poles of the three sections of stator cores are equipped with stator electromagnetic windings. The rotor is formed by a rotor core and permanent magnets. The number of the salient poles of the rotor core is same with the number of the salient poles of a single section of the stator core. The permanent magnets are embedded into the salient poles of the rotor core. The magnetization directions of the permanent magnets are radial and polarities are opposite. According to the single-phase permanent magnet type switched reluctance motor, on the basis of maintaining all advantages of a conventional switched reluctance motor, the inherent torque ripple of the conventional switched reluctance motor is eliminated, at the same time the power density of the motor is improved, the conversion efficiency of power input energy is improved, and the a goal of energy saving is effectively achieved.

Owner:上海鼎特电器有限公司 +1

A cantilever twin-screw water jet propulsion pump

InactiveCN106014975BNo stirringNo pulseMachines/enginesRotary/oscillating piston pump componentsLow noiseInvolute

The invention discloses a cantilever type double-screw water-jet propulsion pump. Besides the components of a common double-screw pump, the cantilever type double-screw water-jet propulsion pump comprises a water inlet, a double-bearing structure for balancing an axial force and a radial force, a double-screw structure and a jet nozzle, wherein a tooth type curve of the double-screw structure is an involute. According to the cantilever type double-screw water-jet propulsion pump, screws are rotated to push water flow, and a carrier in water is pushed forward by a reaction force of high-speed water flow jetted from the cantilever type double-screw water-jet propulsion pump. A cantilever type structure is simple and efficient, and can reduce hydraulic loss fully and generate sufficient thrust to improve the propulsion capability of the carrier in water. The double-screw structure has the characteristics of no stir, no pulsation, smooth output of various media, small mechanical vibration, low noise and the like. Since a pump body structure ensures that a pumping liquid always exists as a sealing liquid in a working element of the pump, the cantilever type double-screw water-jet propulsion pump has high self-suction capacity and is commonly used for multi-phase mixed transportation. For example, the cantilever type double-screw water-jet propulsion pump can be used for transporting oils, water, paste, milk-like substances, pitch and other chemical media.

Owner:JIANGSU UNIV

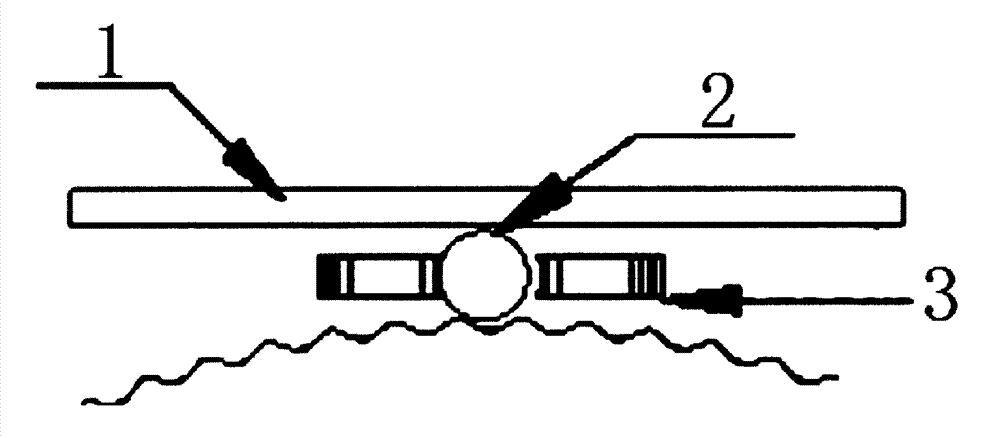

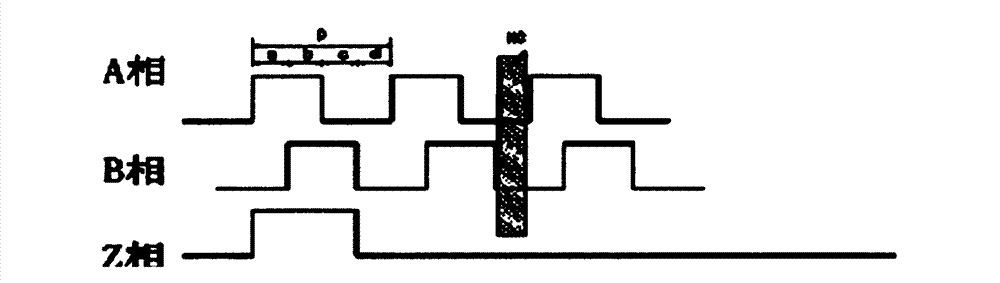

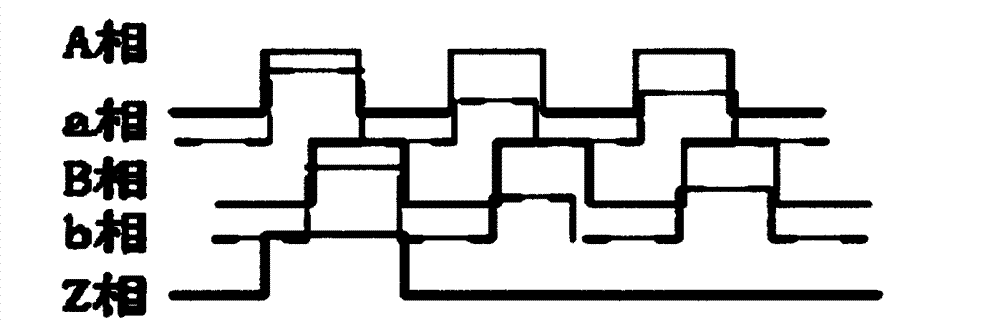

Vibration resistance incremental electronic pulse generator

InactiveCN103716015ANo pulseElectric pulse generator circuitsElectromagnetic interferenceOutput device

The invention discloses a vibration resistance incremental electronic pulse generator. The vibration resistance incremental electronic pulse generator comprises a jump ring. A needle roller is arranged beside the jump ring; the two side edges of the needle roller are provided with a baffle plate groove; the needle roller is engaged with a gear; the center of the gear is provided with a rotating shaft higher than the surface of the gear; the gear is sleeved on the upper portion of the rotating shaft; a moving raster sheet is sleeved on the lower portion of the rotating shaft; an integral optical coupler with an emission receiving device is disposed between the gear and the moving raster sheet; and the integral optical coupler is connected with a signal conversion output device. The vibration resistance incremental electronic pulse generator also comprises a single-chip microcomputer. The single-chip microcomputer (core program) is a key to controlling the pulse generator to accurately emit pulses. The advantages are as follows: during a use process of the generator, the pluses are not generated in case of vibration shaking (mechanical oscillation, shaking back and forth of human hands (a distance between two clicking points)); and the pulses are correctly generated in case of electromagnetic interference.

Owner:余冠军

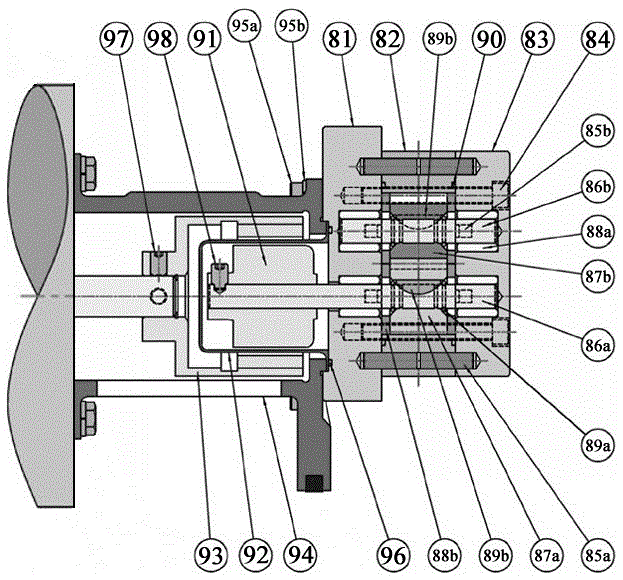

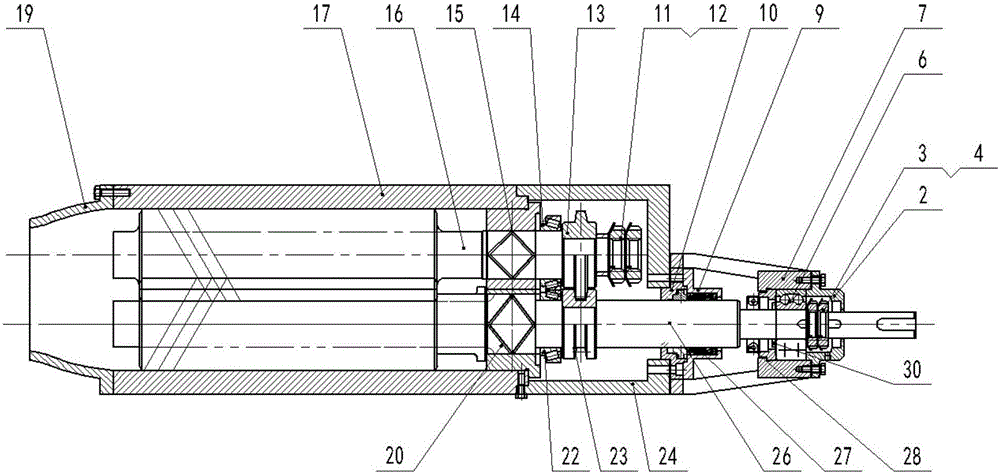

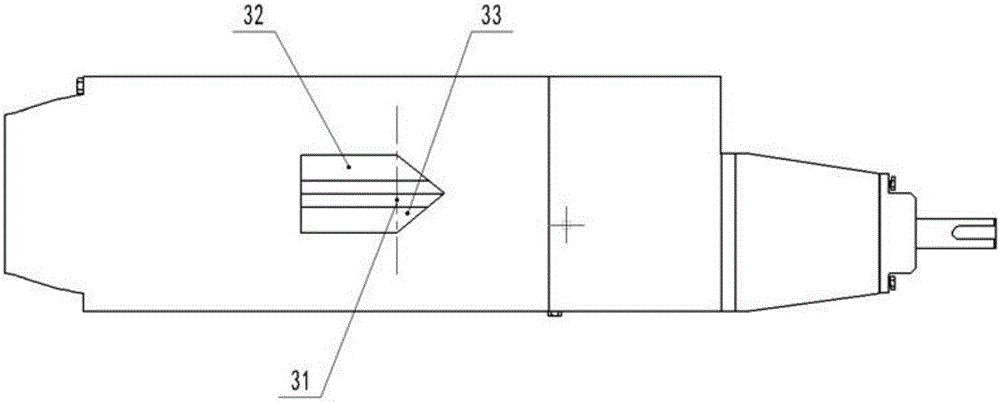

Inverted-V-shaped arc gear metering pump

InactiveCN107100835AFew teethSmall pressure angleRotary piston pumpsRotary piston liquid enginesMetering pumpGear tooth

The invention discloses an inverted V-shaped arc gear metering pump, and belongs to the technical field of gear metering pumps. The inverted V-shaped arc gear metering pump comprises a gear case, two splined shafts, a plurality of transmission bevel gears and a plurality of inverted V-shaped arc gear sets; the driving spiral gears are arranged on the end portions of the two splined shafts, and the two splined shafts are arranged in the gear case side by side and enable the two driving spiral gears on the end portions of the two splined shafts to be engaged with each other; the multiple inverted V-shaped arc gear sets are arranged on the two splined shafts and located between the transmission bevel gears at two ends of the splined shafts; and a baffle is arranged between every two adjacent inverted-V-shaped arc gear sets to enable an independent cavity body to be formed between each inverted-V-shaped arc gear set and the gear case. The metering pump has less gear teeth, and high flow quantity, is stable to rotate, cannot result in the phenomena of flow fluctuation and material being trapped, can achieve quantitative material extrusion, and is very low in weight deviation.

Owner:珠海市洪富食品机械制造有限公司

Precision control method and device for adding micro-liquid

InactiveCN101833293BRealize precise controlThe control accuracy reachesProgramme control in sequence/logic controllersMemory circuitsMotor control

The invention discloses a precision control method and a precision control device for adding micro-liquid. The precision control device comprises an ARM9 processor, a color LCD display touch screen, an Ethernet interface circuit, a high-precision speed regulation circuit, a speed monitoring circuit, a flow detection circuit, a liquid level monitoring circuit, an alarm circuit, an SD card interface circuit, a USB interface circuit, a PWMDAC circuit, an SDRAM memory circuit, a program memory circuit flash, and a motor control interface circuit, wherein the circuits are mutually connected and the precision control for adding the micro-liquid addition is realized by software programming. By using the rate tracking technology to timely change the needed liquid flow, the precision control method and the precision control device for adding the micro-liquid realize the accurate control of micro-liquid addition in the production process, achieve the control precision of 1 percent, and have thefunctions of local automatic alarm and remote automatic alarm under the abnormal condition. The precision control method and the precision control device have convenient control parameter input, and can be organically integrated with the conventional production equipment to greatly improve the production efficiency and save the production cost.

Owner:EAST CHINA NORMAL UNIV

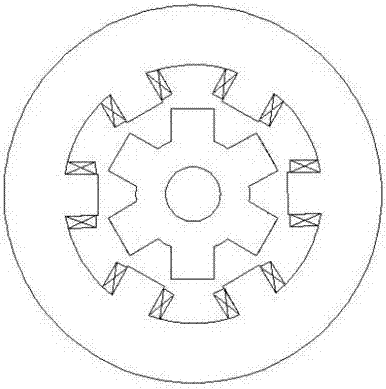

Non-circular gear planetary gear train hydraulic motor

InactiveCN104061117ASatisfy the optimal design conditionsLarge displacementRotary piston enginesAviationHydraulic motor

The invention relates to a non-circular gear planetary gear train hydraulic motor, comprising a circumferential wheel with inner teeth, a sun gear with outer teeth, a planetary cylindrical gear, a distributor, a front cover, a rear cover, etc. The hydraulic motor is characterized by the positions of flow distribution holes, shapes of tooth profiles, the tooth number of each gear and the design structure of a non-circular gear planetary gear train. Through displacement design and discretization processing technology, a non-circular gear train can be designed at will, so demands of the non-circular gear planetary gear train hydraulic motor for actual technical characteristic parameters can be met. The non-circular gear planetary gear train hydraulic motor has wide application prospects in fields of engineering machinery, heavy machinery, ships, machine tools, aviation and spaceflight.

Owner:BEIJING FENGYUAN TECH

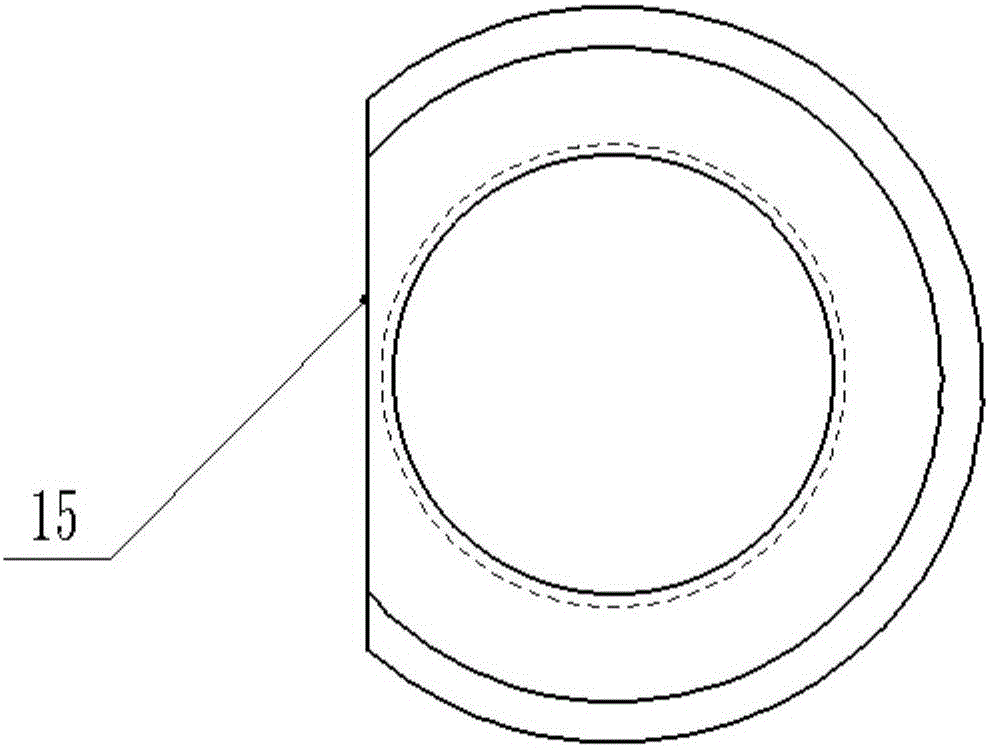

Single-suction 2G screw pump shell

InactiveCN104074748AReduce the number of partsEasy assemblyMachines/enginesRotary/oscillating piston pump componentsEngineeringSafety valve

The invention relates to a single-suction 2G screw pump shell. The shell is in an integrated structure, the front end of the shell is provided with a front end cover, and the rear end of the shell is provided with a rear end cover; a drive shaft hole and a driven shaft hole which are communicated front and back are formed in the center of the shell; two sides of the shell are respectively provided with a connecting inlet flange end and a connecting outlet flange end; the lower part of the shell is provided with a heating air inlet, a heating air outlet and a sump oil discharge hole; the upper part of the shell is provided with a safety valve threaded hole and a safety valve pressure-relief hole; a local annular interlayer is arranged at the lower part of the shell, so that the heating area of a single-suction 2G screw pump can be increased, and transportation of high-viscosity media is applicable; base positioning holes are formed in the four corners of the bottom of the shell. According to the utility model, a pump body is formed with the front end cover and the rear end cover at one time, the parts are few, the assembly is simple, screws for positioning are not required, the assembling accuracy is high, the end covers have high supporting force, loosening and leakage are not caused after long-time working, and the performance is improved; the shell is suitable for medium with a kinematic viscosity of 6 to 6,000,000 mm2 / s and a flow of 0.3 to 350 m<3> / h; the production cost can be reduced, and good economic benefits and social benefits can be achieved.

Owner:上海诺科泵业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com