Backflow hydraulic mechanical automatic variable speed transmission device

An automatic speed change and transmission technology, applied in the direction of fluid transmission, transmission, mechanical equipment, etc., can solve the problems of low efficiency, development restrictions, and low transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

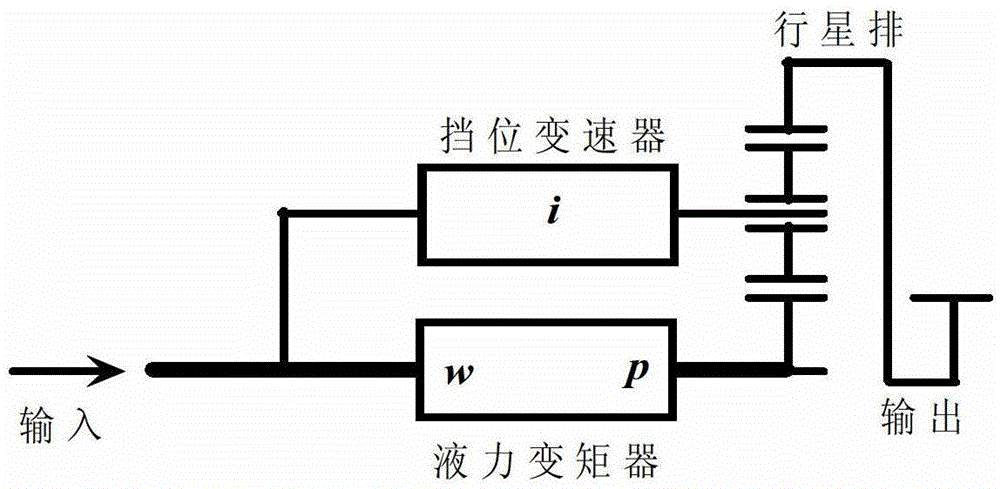

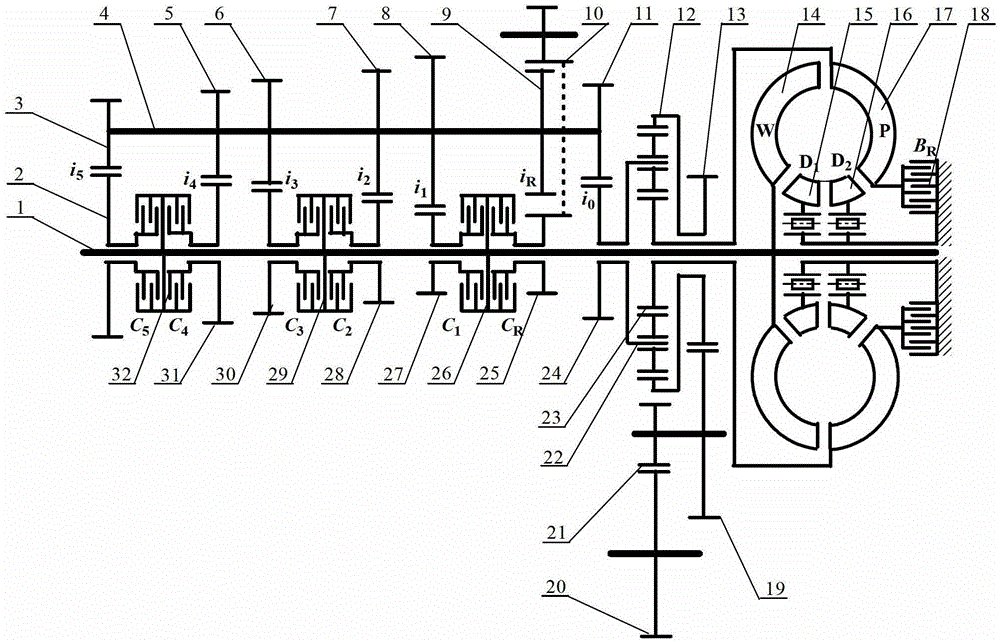

[0026] Such as figure 1 and figure 2 Shown: a return type hydromechanical automatic variable speed transmission, including an input shaft 1, an intermediate shaft 4, a planetary row and a hydraulic torque converter, wherein the planetary row includes a planetary carrier 22, a sun gear 23 and a ring gear 12 , the hydraulic torque converter includes a pump wheel 17 and a turbine wheel 14, one end of the intermediate shaft 4 is connected to the input shaft 1, the other end is connected to the planet carrier 22, and the sun gear 23 is connected to the pump wheel 17 connected, the turbine 14 is fixedly connected with the input shaft 1, the input shaft 1 and the intermediate shaft 4 are arranged in parallel, wherein the input shaft 1 is provided with a transition driven gear 24, and the intermediate shaft 4 is fixedly sleeved with The transition driving gear 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com