Mechanism for tooth clearance adjustment and linear actuation

A linear actuator, backlash technology, applied to components with teeth, mechanical equipment, belts/chains/gears, etc., can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

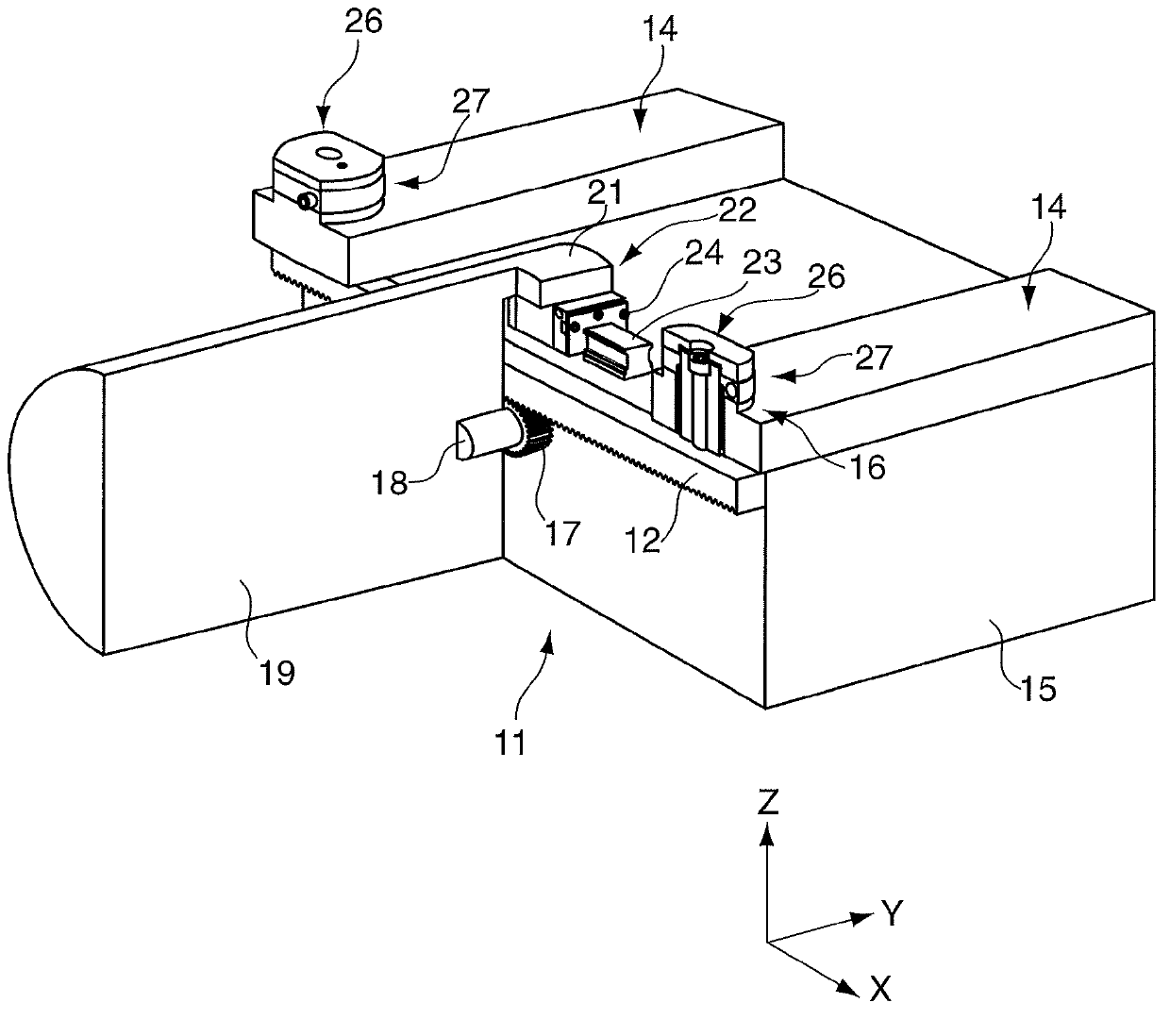

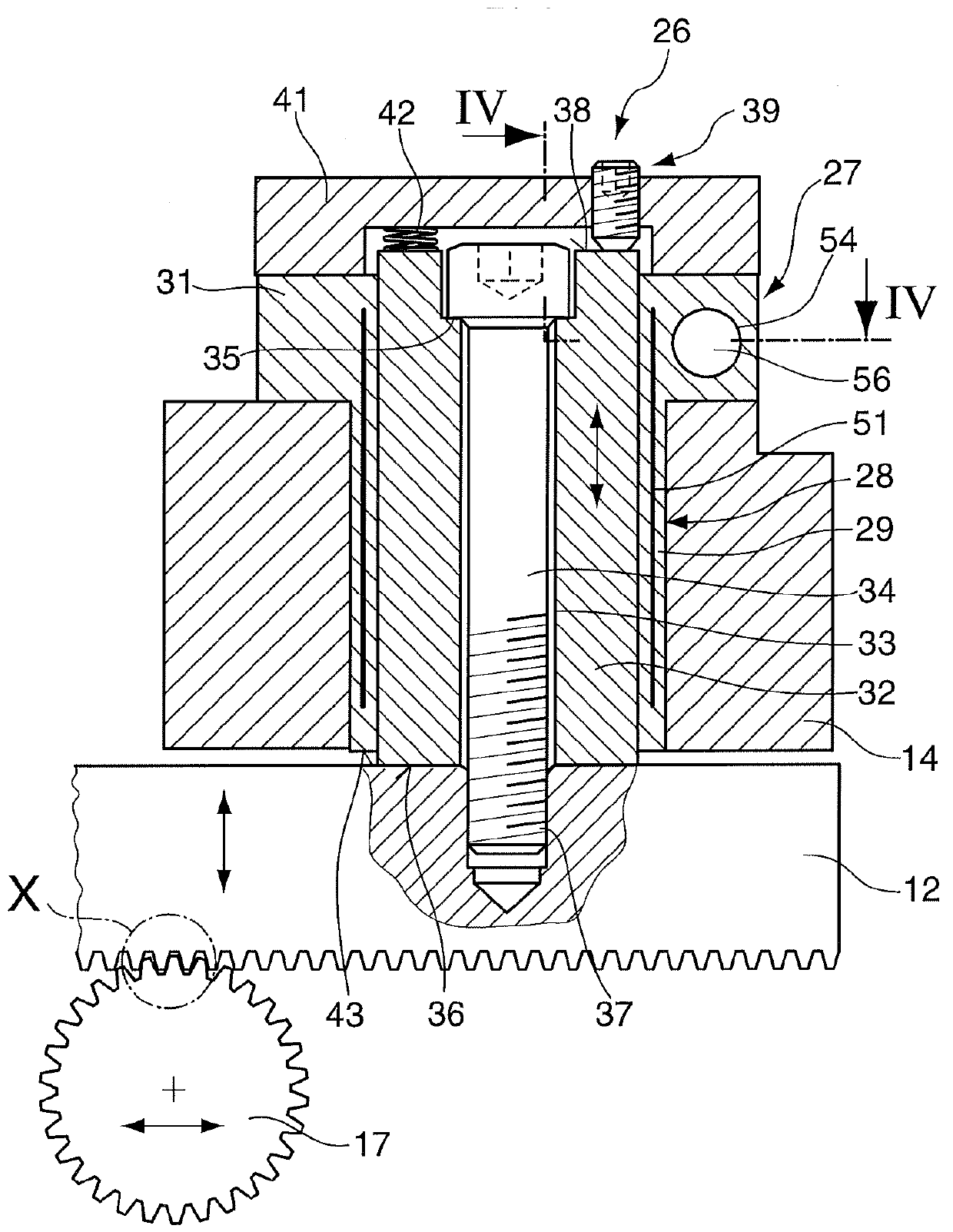

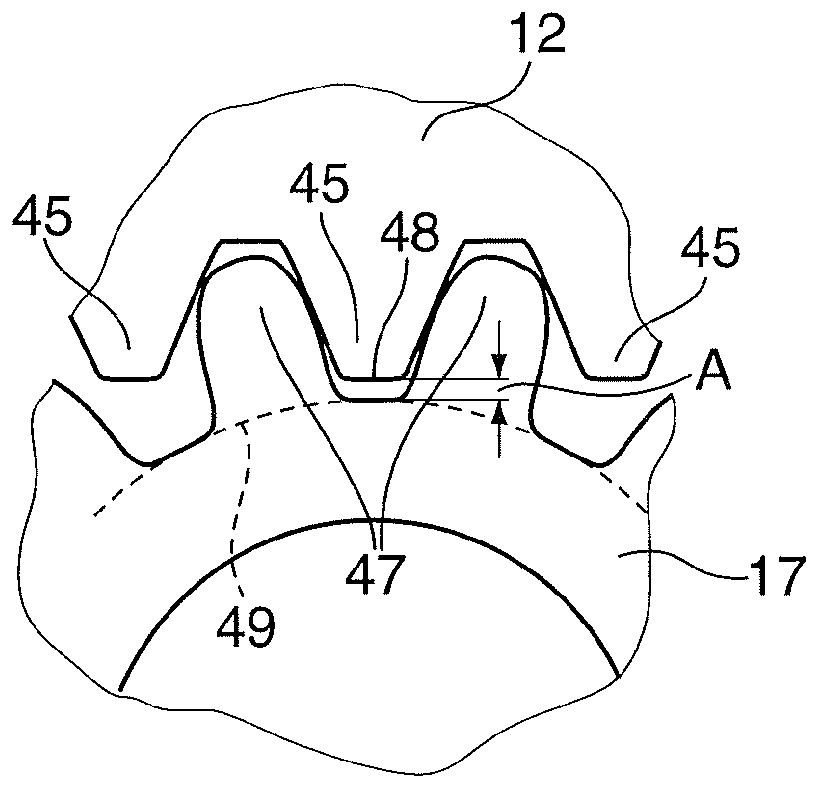

[0028] exist figure 1 A perspective view of a linear actuator 11 with a mechanism 10 for backlash adjustment is shown in . The mechanism 10 for backlash adjustment comprises a holding element 21 on which the gear wheel 17 is mounted. This gear 17 is in contact with the rack 12 or an additional gear contained or mounted via the carrier element 14 . In order to adjust the backlash A between the gear 17 and the rack 12 or between the gear 17 and an additional gear, a backlash adjusting device 26 with a fastening device 27 is provided, wherein said fastening device is Figures 2 to 4 in more detail.

[0029] in accordance with figure 1 In an embodiment of the present invention, the toothed rack 12 is connected to a carrier element 14 which in turn is detachably connected to a base (base body) 15 . The carrier element 14 can also be provided in one piece with the base 15 . The base 15 is, for example, part of a machine tool or processing machine, in particular a laser processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com