Sewage heat energy recovery system

A heat recovery and sewage technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve secondary pollution, sewage heat recovery system operation performance confirmation and energy saving confirmation have not been effectively resolved, water resources Waste and other issues to achieve the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

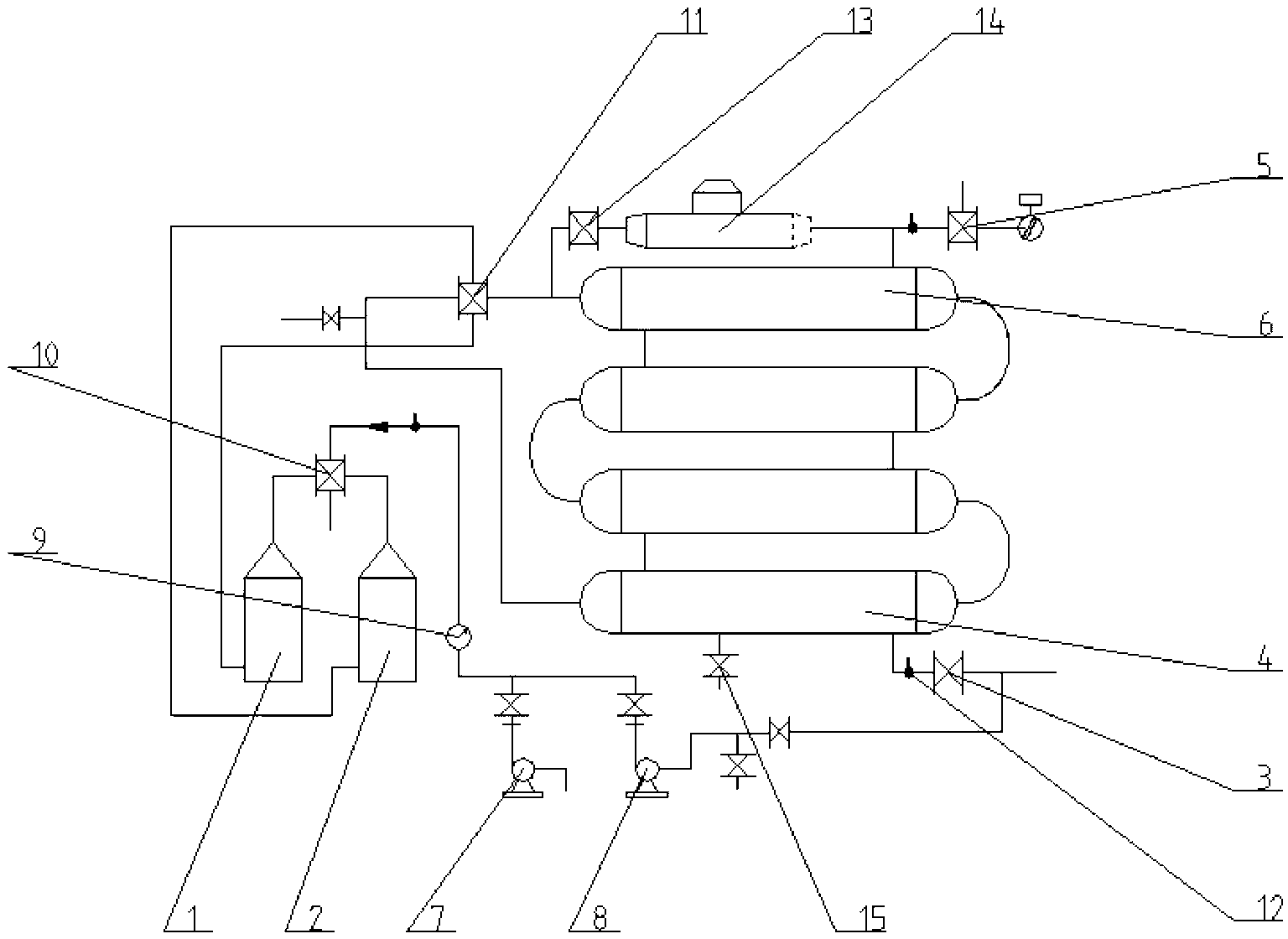

[0015] This example figure 1 As shown, a sewage heat recovery system includes a filter device and a heat exchange device. The filter device and the heat exchange device are communicated through pipelines. The filter device includes two filters 1 arranged in parallel, 2. The heat exchange device includes multiple sets of heat exchangers, which are connected in series through pipelines, wherein the multiple sets of heat exchangers include the beginning heat exchanger 4 communicating with the normal temperature clean water inlet 3 and the The terminal heat exchanger 6 communicating with the high-temperature drain port 5, the terminal heat exchanger 6 communicates with the filter device through a pipe, and the pipe connecting the filter device and the heat exchange device is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com