Device and method for testing wall shear stress based on flexible heat-sensitive sensors

A technology of thermal sensor and testing device, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problem of inability to measure the shear stress of underwater wall, achieve the effect of small thickness, improve work efficiency, and reduce waste of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

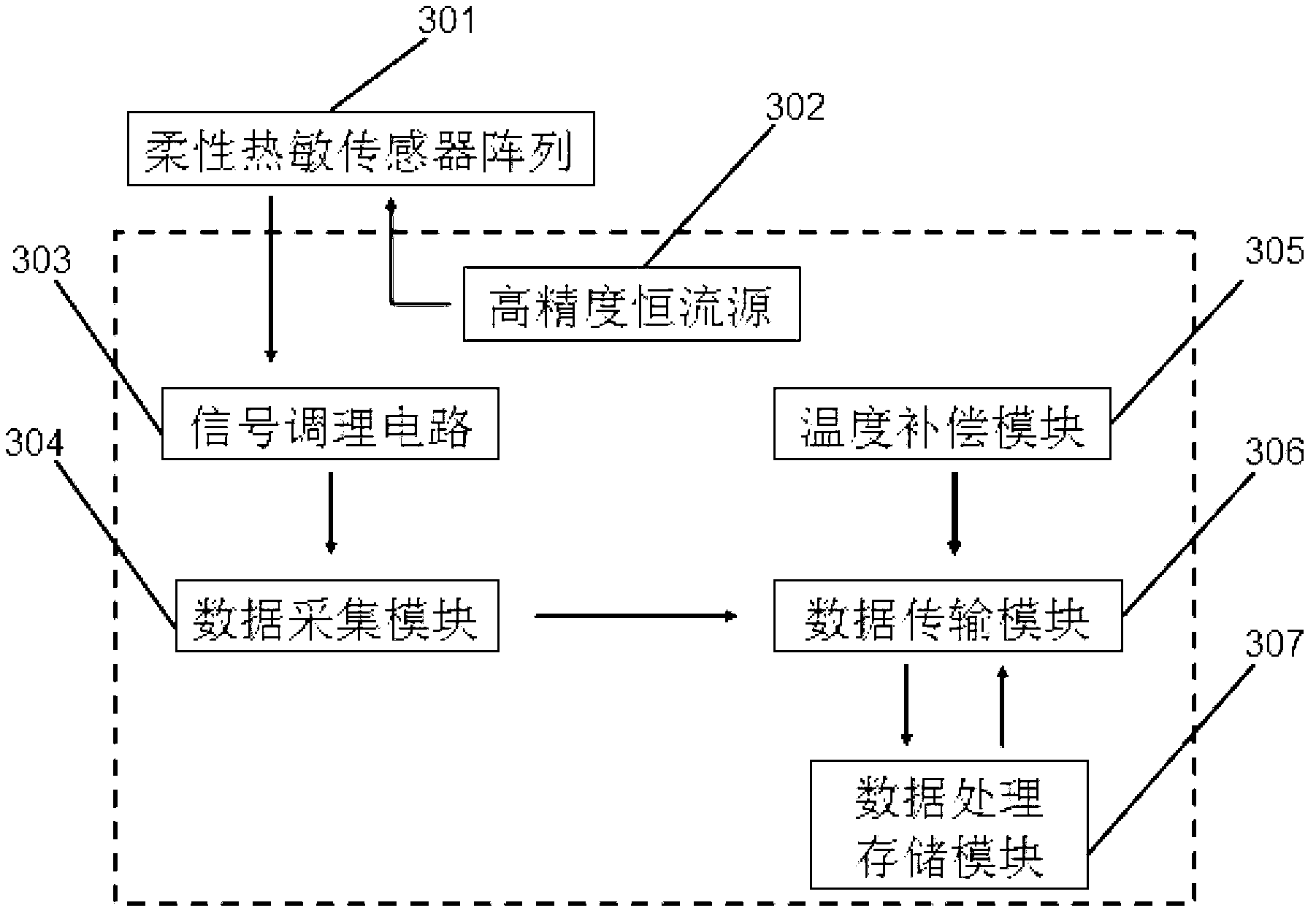

[0024] Wall shear stress testing device based on flexible thermal sensors, see image 3 , including a flexible thermal sensor array 301, a high-precision constant current source 302, a signal conditioning circuit 303, a data acquisition module 304, a temperature compensation module 305, a data transmission module 306, and a data processing storage module 307; the high-precision constant current source 302 Provide constant current excitation for the flexible thermal sensor array 301; the flexible thermal sensor array 301 senses the change of the wall shear stress of the flow field, transmits the analog voltage signal u to the signal conditioning circuit 303 for amplification and filtering, and obtains the conditioned signal u', data The acquisition module 304 converts the conditioned signal u' from an analog signal into a digital signal U and then inputs it to the data transmission module 306; the temperature compensation module 305 transmits the ambient temperature signal to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com