Device and method for simulating temperature variation of Pt100 thermal resistor

A temperature change, simulation device technology, applied in electrical testing/monitoring and other directions to achieve the effect of automatic regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the specific implementation and structure of the Pt100 thermal resistance temperature change simulation device and method proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

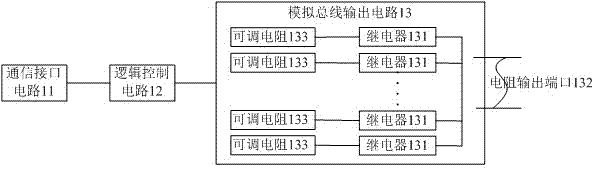

[0027] Such as figure 1 As shown, a Pt100 thermal resistance temperature change simulation device provided by the embodiment of the present invention includes: a communication interface circuit 11, a logic control circuit 12, an analog bus output circuit 13, and the analog bus output circuit 13 includes a plurality of relays 131, Resistance output port 132 and adjustable resistance 133, the two contacts of the relay 131 are connected to the two ends of the corresponding resistance value on the adjustable resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com