Electronic device encapsulated with welding end ring and electronic equipment provided with electronic device

A technology for electronic devices and solder terminals, applied in the field of electronic equipment, can solve the problems of early failure, cracks in solder joints, poor product reliability, etc., and achieve the effect of reducing application concentration, large scalable paths, and not easy to fail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

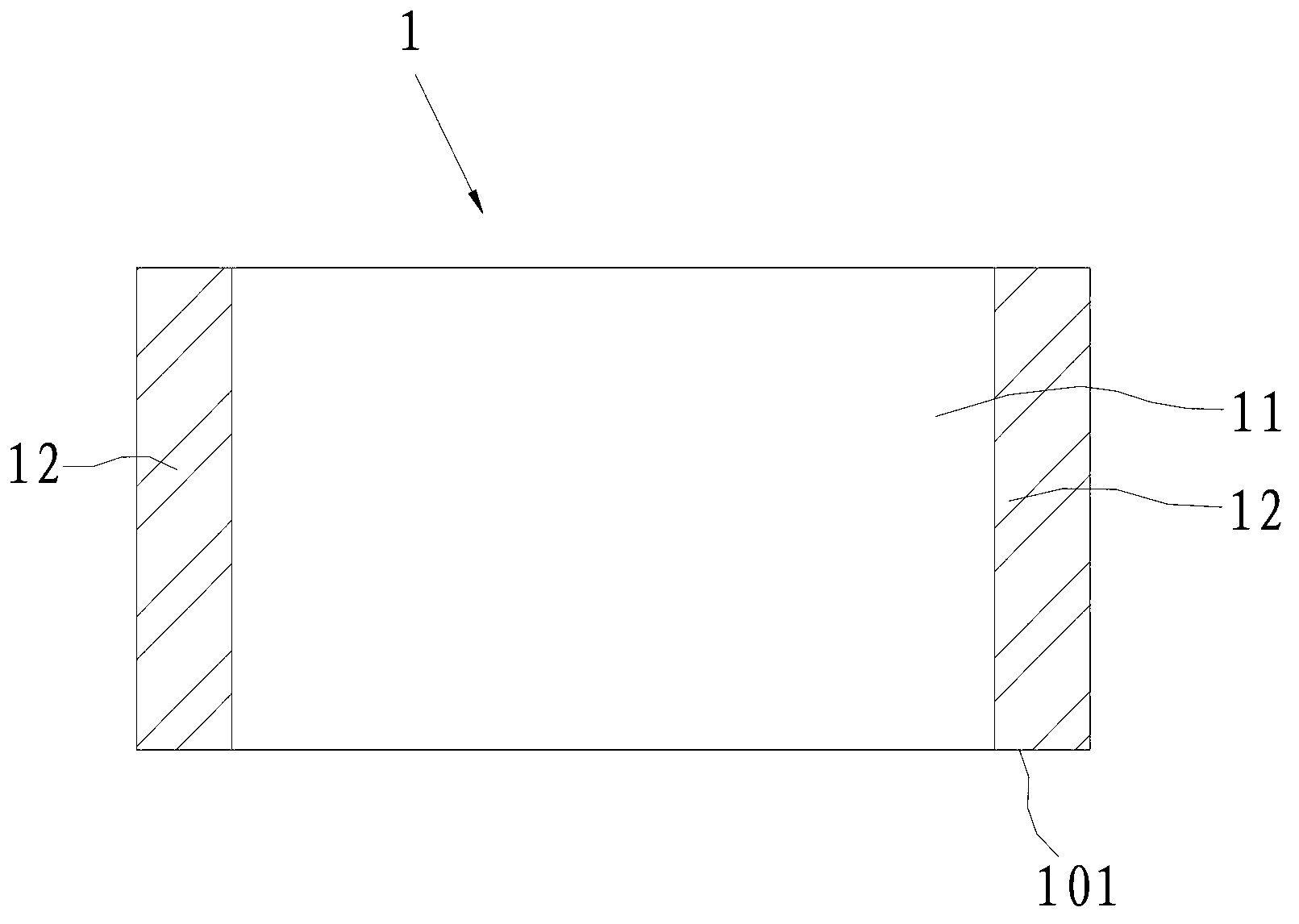

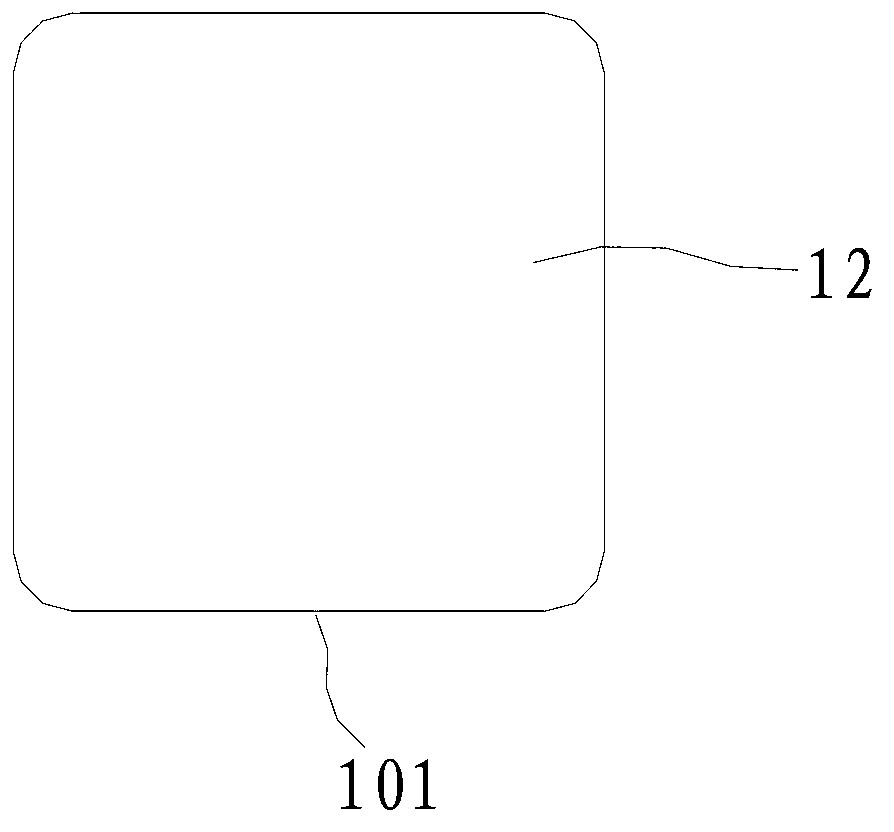

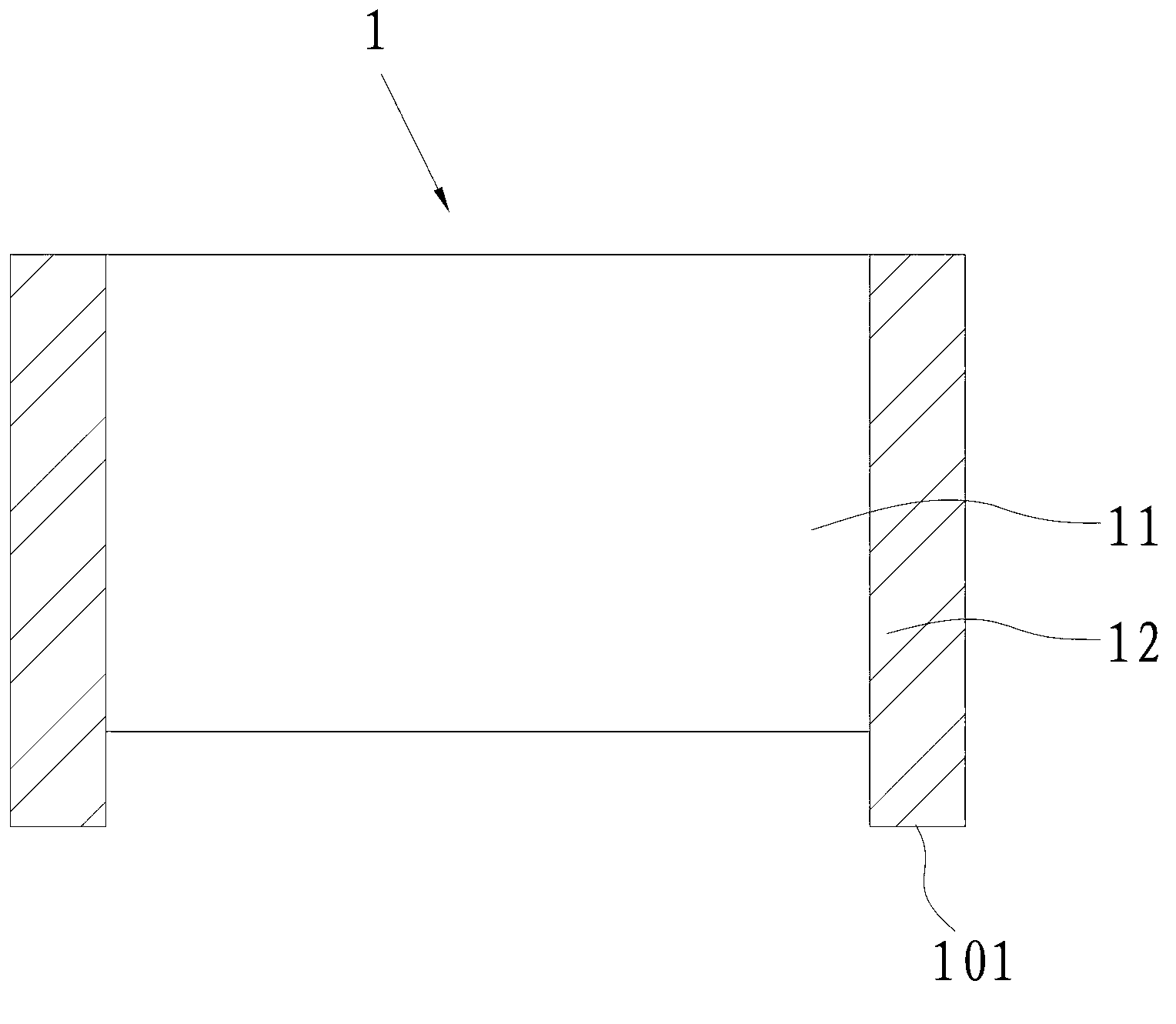

[0030] Such as figure 1 with figure 2 As shown, an electronic device 1 packaged with solder end rings provided by the embodiment of the present invention includes a body 11 and a solder end ring 12 , and the body 11 can be made of insulating materials such as ceramics and plastics. The welding end ring 12 is sleeved on the outer peripheral wall of the body 11 , and the welding end ring 12 may be annular. And the welding end ring 12 has a plane welding end 101 , and the plane welding end 101 is flush with the outer peripheral wall of the body 11 , that is, the end surface of the plane welding end 101 is flush with the lowest point of the outer peripheral wall of the body 11 . The outer peripheral wall of the body 11 can be cylindrical, and it is arranged transversely, and the end surface of the plane welding end 101 is tangent to the cylindrical body 11 . Cracks are not easy to occur at the solder joints and the application concentration is reduced. Even if cracks occur, the...

Embodiment 2

[0042] Such as Figure 7 with Figure 8 As shown, on the basis of the electronic device 1 packaged with the solder end ring 12 provided in Embodiment 1, the solder end ring 12 of the electronic device 1 in this embodiment also includes a middle solder end ring packaged in the middle section of the body 11 12. There can be two middle welding end rings 12 or other appropriate numbers, and the distance between the middle welding end rings 12 and the two end welding end rings 12 is set. The middle solder end ring 12 and the end solder ring 12 can be packaged in the body 11 through MELF. By adding the solder end ring 12 in the middle, compared with the electronic device 1 having only two solder end rings 12, the stress concentration of the solder end rings 12 at both ends can be effectively alleviated, and the stress can be distributed to each solder end ring 12, It is conducive to improving reliability; setting the contact mode between the solder end ring 12 and the pad to be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com