Micromechanical acoustic transducer device and corresponding manufacturing method

An acoustic transducer and micro-mechanical technology, applied in the directions of microstructure devices, manufacturing microstructure devices, speaker screens, etc., can solve the problems of multi-package technology, cost-intensive packaging, cost-intensive, etc., and achieve high integration density and low structure height. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

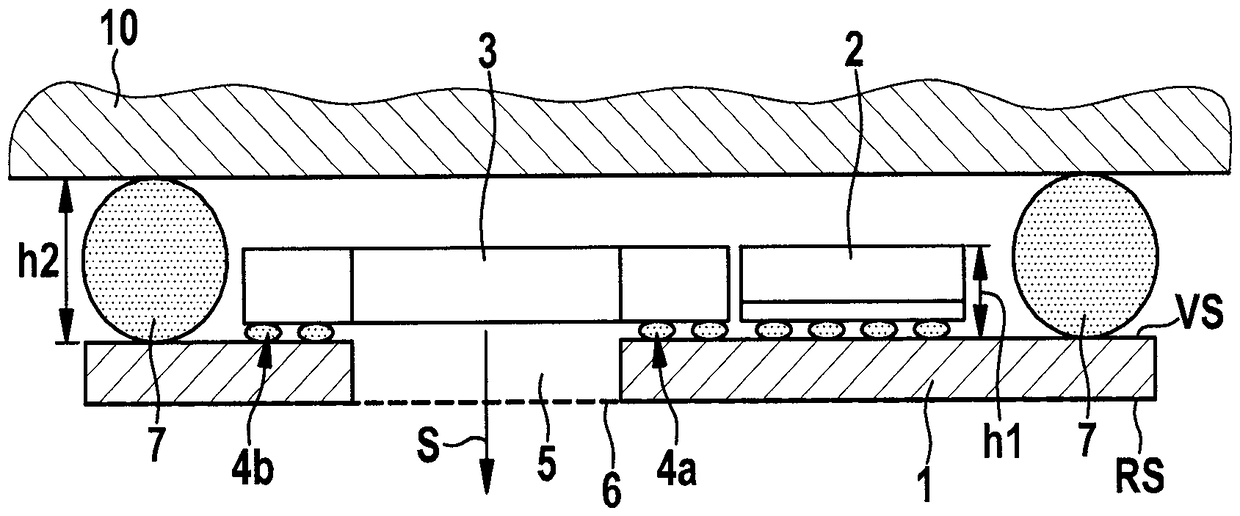

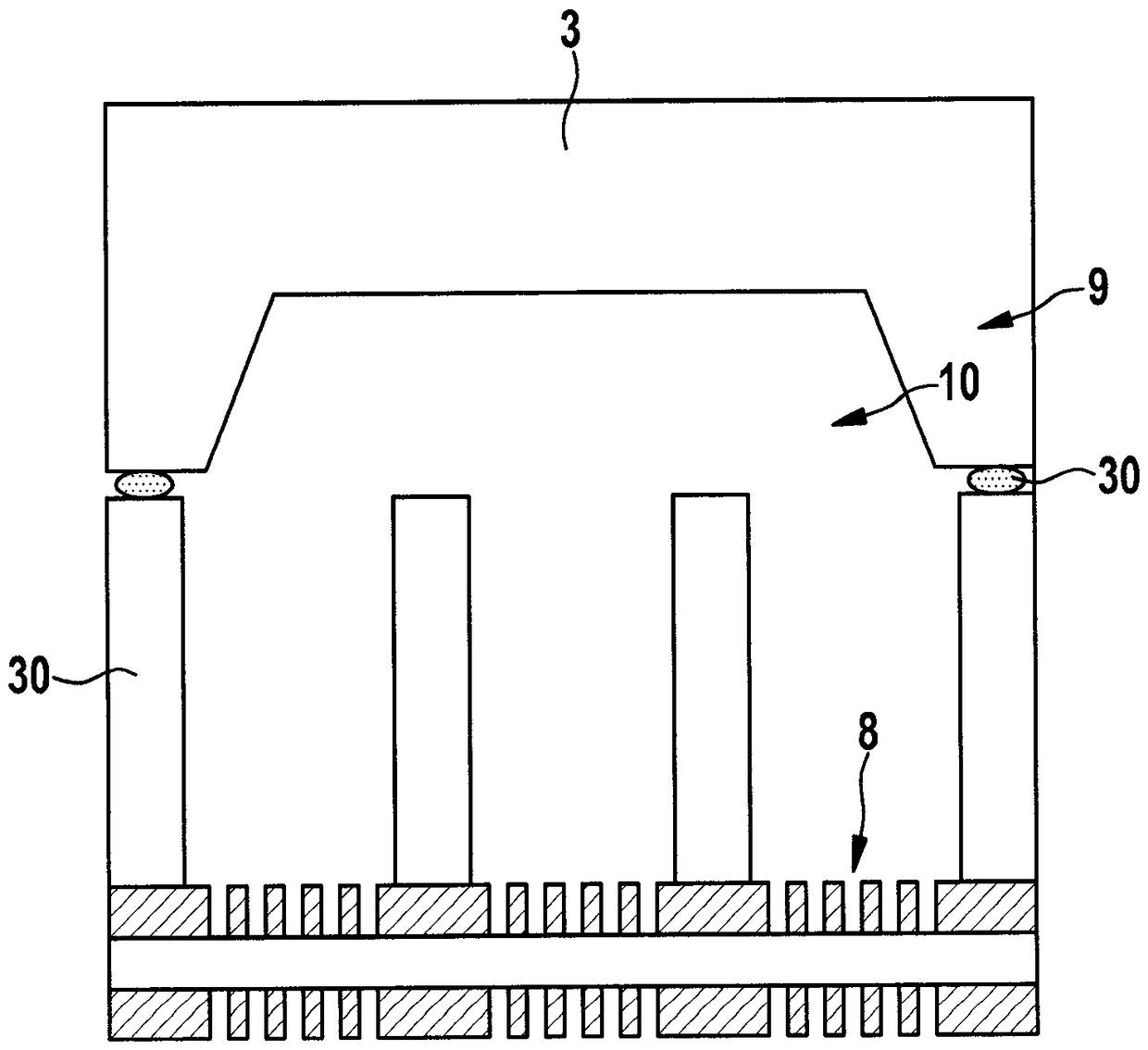

[0023] exist figure 1 , reference numeral 1 denotes an electrical printed circuit board, which has a front side VS and a back side RS. On the front side VS, the printed circuit board 1 is flip-chip equipped with an ASIC 2 and a micromechanical speaker structure 3 . Electrically small solder balls as flip-chip bonds (Flip-Chip-Bond) are designated with reference numeral 4a. For reasons of simplification, the rewiring (Umverdrahtung) implemented in the printed circuit board is figure 1 is not shown. The micromechanical loudspeaker structure 3 can be protected against the environment, for example, by a surrounding solder frame 4b. As an alternative thereto, an adhesive film can be provided instead of the surrounding solder frame 4b, whereby no electrical contact is made, but only mechanical protection.

[0024] Furthermore, the printed circuit board 1 has a hole-shaped opening 5 which is mechanically closed on the rear side RS of the printed circuit board 1 with a protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com