Multi-directional racetrack rotating cathode for PVD array applications

一种旋转靶、旋转轴的技术,应用在真空蒸发镀覆、涂层、放电管等方向,能够解决易于出错、耗时、可动磁棒或磁轭成本密集等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Reference will now be made in detail to various embodiments of the invention, one or more examples of which are illustrated in the accompanying drawings. In the following description of the figures, the same reference numerals represent the same components. In general, only the differences with respect to the respective embodiments are described. Each example is provided by way of explanation of the invention, and each example is not meant as a limitation of the invention. Furthermore, features illustrated or described as part of one embodiment can be used on or in conjunction with other embodiments to yield a still further embodiment. This description is intended to cover such modifications and variations.

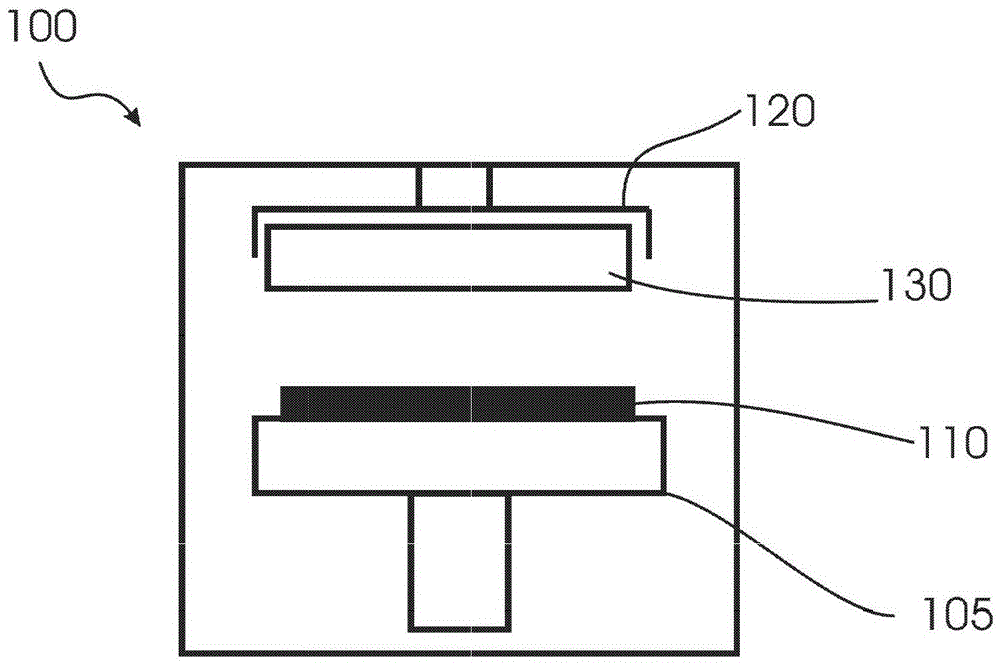

[0025] figure 1 Illustrated is a deposition chamber suitable for a PVD process according to embodiments described herein. Typically, the chamber 100 includes a substrate support 105 adapted to transfer a substrate 110 . Furthermore, the chamber 100 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com