Garbage sorting device capable of cleaning remaining materials on screen cloth

A sorting device and screen technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of easy adhesion and accumulation, large garbage volume, etc., and achieve simple operation principle, avoid impact, prevent corrosion or deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

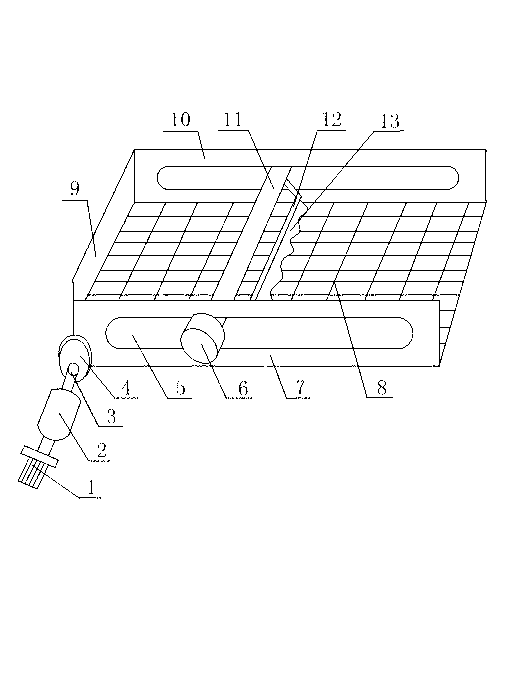

[0016] Such as figure 1 As shown, a garbage sorting device capable of cleaning the remaining material of a screen includes a screen 8. A baffle is provided on the side wall of the screen 8. The baffle includes a baffle 7, a baffle 9 and a block. Plate three 10, baffle one 7 and baffle three 10 are parallel, and at the same time perpendicularly connected with baffle two 9, and baffle two 9 is set between baffle one 7 and baffle three 10, and the screen 8 is set in the block Plate one 7, baffle two 9 and baffle three 10 surround the area, and the screen 8 can move in this area. A cleaning system is provided above the screen 8. The two ends of the cleaning system are respectively connected to the baffle one 7. Connected to the baffle 10, the bottom end surface of the cleaning system is in contact with the top end surface of the screen 8. Three baffles form a structure, leaving one end open as a through hole for garbage cleaning. The cleaning system cleans up the garbage, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com