Metal low-pressure casting mold

A low-pressure casting and metal mold technology, which is applied in the field of casting molds, can solve problems such as waste products and abnormal exhaust, and achieve the effects of reducing gas production, simple structure, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

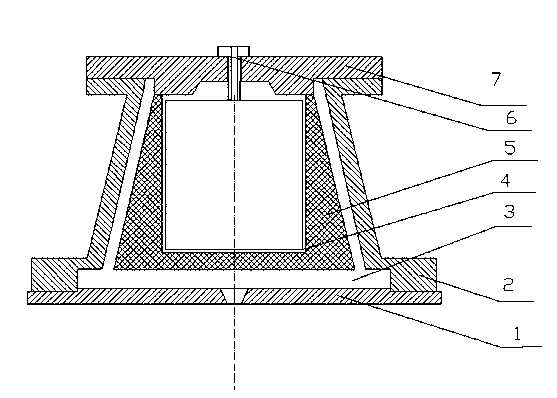

[0012] like figure 1 As shown, the metal type low-pressure casting mold of the present invention comprises a bottom plate 1, a left and right mold 2, a sand core 5, a keel 4, a bolt 6 and an upper mold 7.

[0013] There is a low-pressure pouring port in the middle of the bottom plate 1, and the outer edge is concave.

[0014] Upper mold 7 is arranged on left and right mold 2 upper ends, and keel 4 is arranged on the inner side of left and right mold 2 and is connected and fixed with upper mold 7 by bolt 6, and sand core 5 is arranged on the outside of keel 4 and is fixed.

[0015] The keel 4 is a hollow cylinder with air holes evenly distributed on the outer surface, a vertical through hole is opened in the middle of the bolt 6, and exhaust gas is opened at equal intervals from top to bottom at the connection of the Huff structure of the left and right molds 2 hole.

[0016] Such a structure, when in use, applies pressure to the molten metal in the crucible, then enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com