Multifunctional composite numerical control machine tool

A composite CNC machine tool and multi-functional technology, applied in the field of lathes, can solve the problems of low machining accuracy and production efficiency, inconvenient operation, and high labor intensity, and achieve the effects of high machining accuracy, easy maintenance, and reasonable structural layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings.

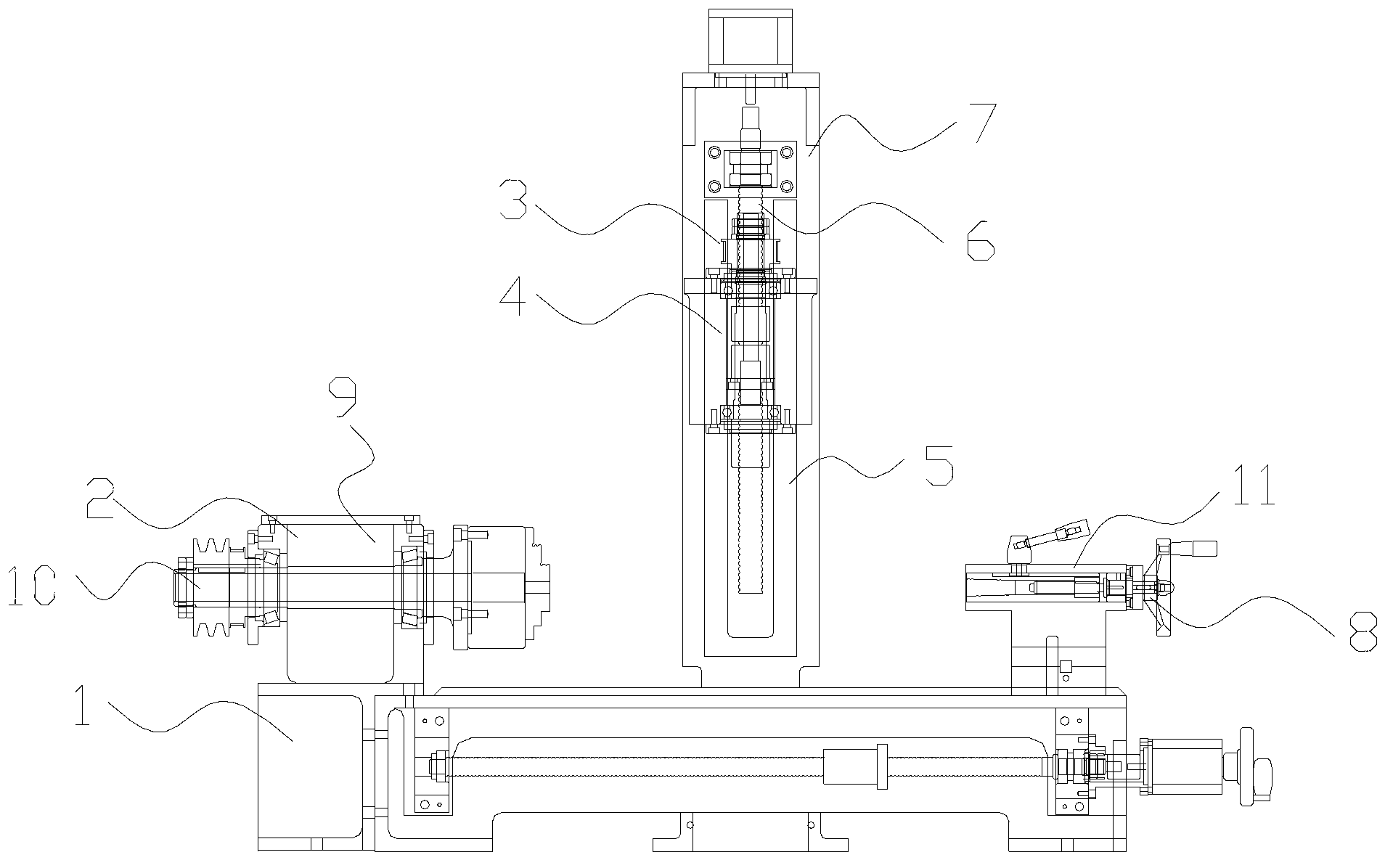

[0018] In consideration of the above-mentioned problems of the prior art, according to an aspect disclosed by the present invention, the present invention adopts the following technical solutions: a multifunctional composite numerical control machine tool, the machine tool body 1 includes a lathe unit 2, a drilling and milling unit 3 and a milling unit 4, the lathe The unit 2 is installed horizontally on the main body of the machine tool 1. The main body of the machine tool 1 can be installed on a solid wooden or iron workbench. It also has a fully protective chip shield, which provides safety protection for the user and facilitates removal of chips. , to keep the machine tool and the working environment clean and beautiful, the main body of the machine tool 1 is vertically provided with a column 5, the column 5 is provided with a drilling and milling headstock 6 which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com