Mechanical arm and catching mechanism of drying device

A technology of drying equipment and grabbing mechanism, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., which can solve the problems of radiation hazards and high labor costs for workers, and achieve the effect of eliminating personal hazards and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

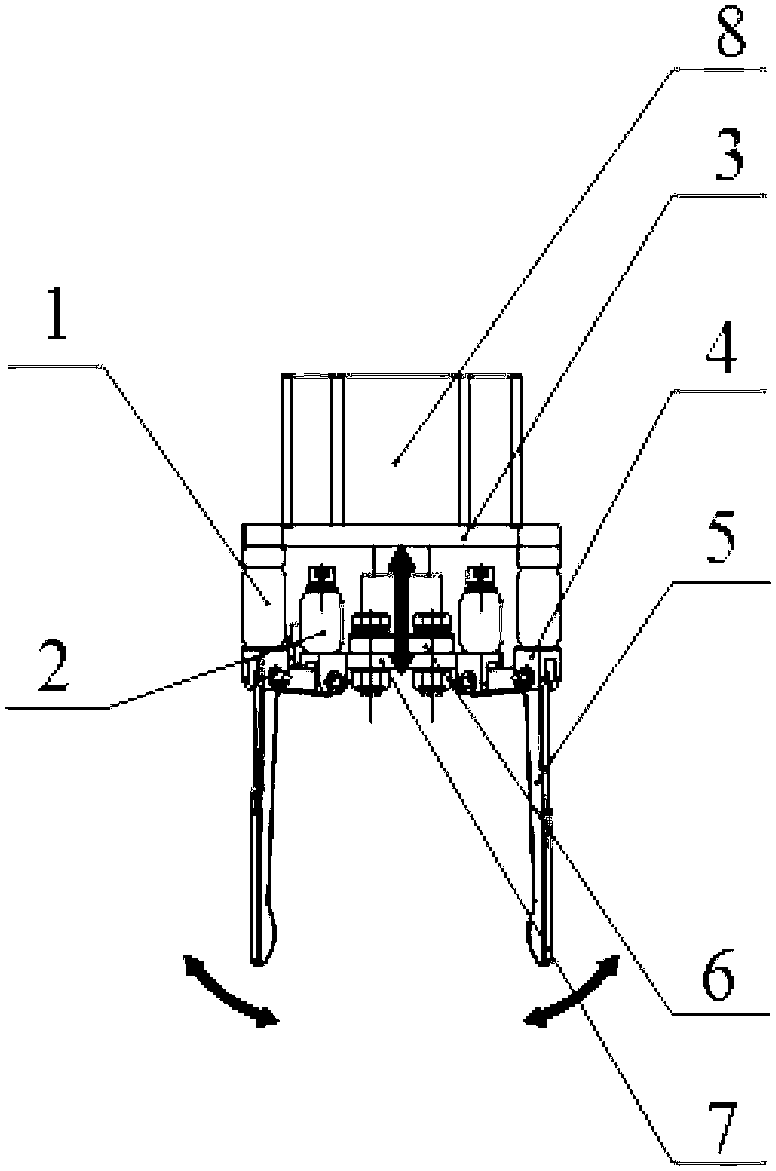

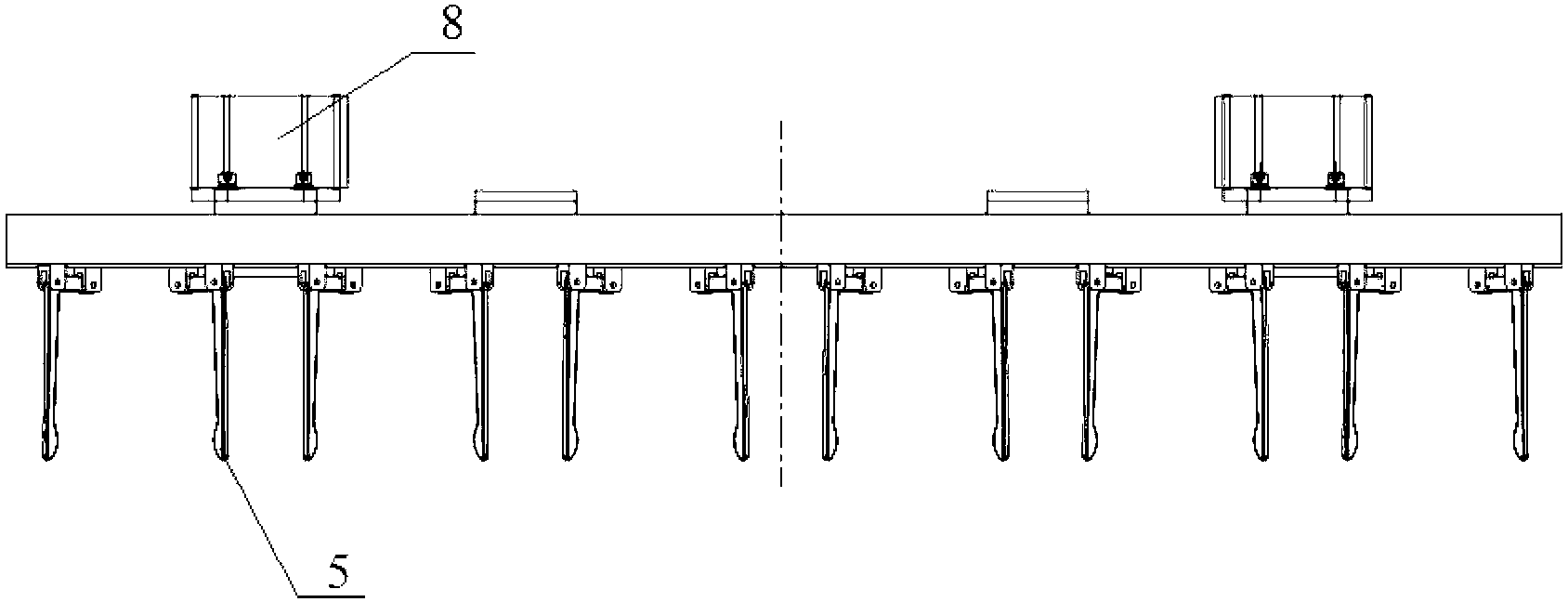

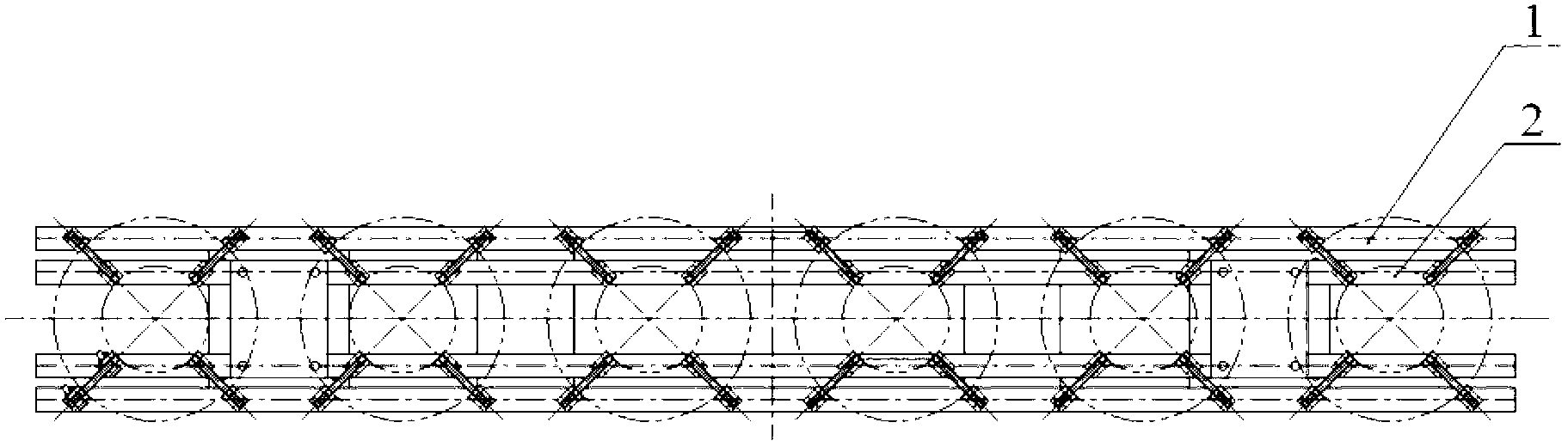

[0024] see figure 1 As shown, the manipulator of the drying equipment of the present invention is a grabbing mechanism. The gripping mechanism includes an outer rigid rod 1 and an inner rigid rod 2 . The two symmetrical outer rigid rods 1 are tightly connected with the power unit fixing plate 3 , and the two symmetrical inner rigid rods 2 are tightly connected with the bottom connecting plate 7 . A plurality of hinge devices 4 are respectively fixed on the outer rigid bar 1 and the inner rigid bar 2 . There are multiple L-shaped grippers 5 with two pin holes (the shape of the end depends on the different objects to be grasped), and one pin hole of the L-shaped gripper 5 is connected to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com