Bearing base plate production equipment

A technology for production equipment and carrier substrates, applied in the direction of mechanical processing/deformation, which can solve the problems of long production time and inability to increase production capacity, and achieve the effects of light weight, high resistance to weight, and fast mass production of carrier substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]In order to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

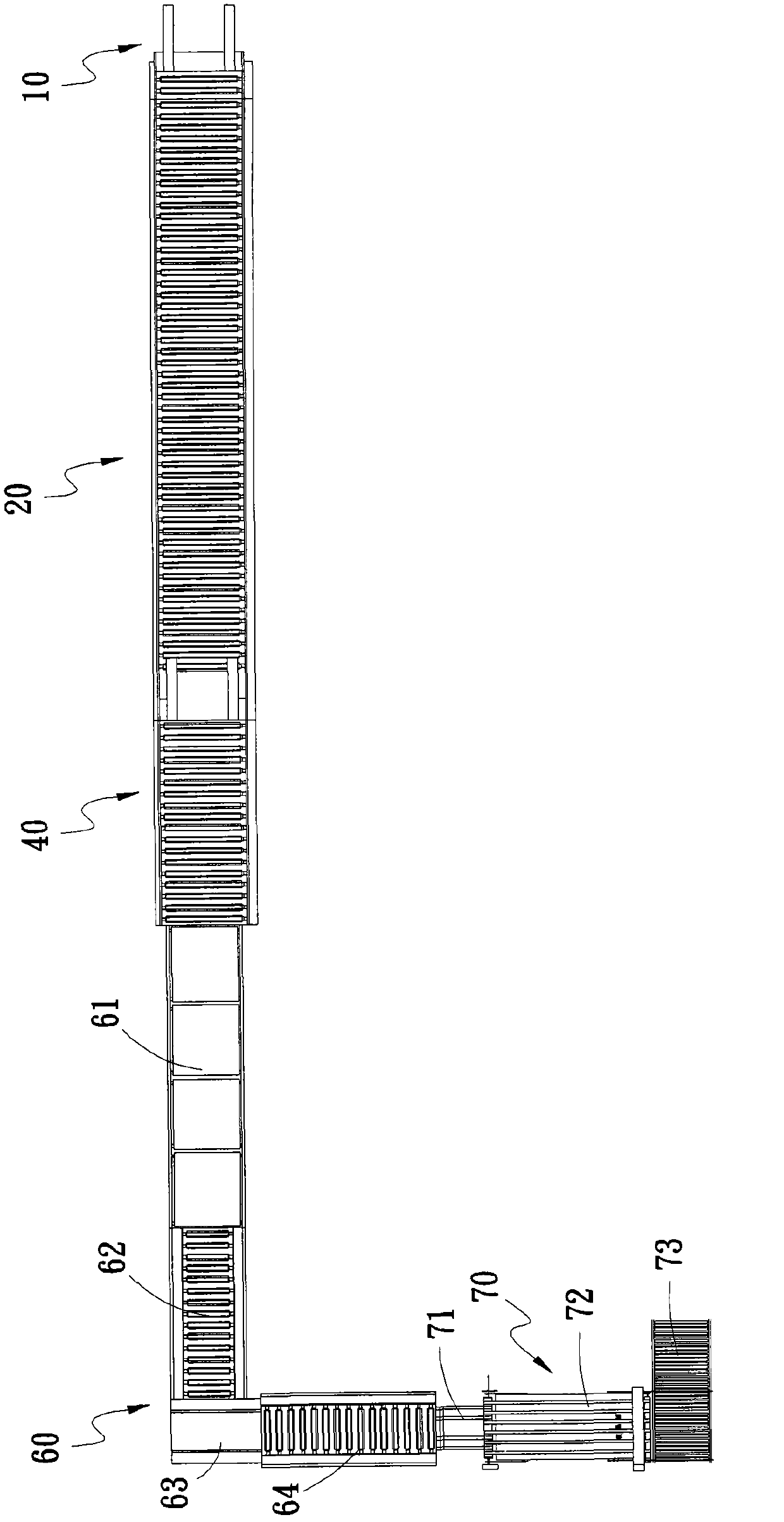

[0039] Please refer to figure 1 and figure 2 The carrier substrate production equipment of the present invention includes a first feeding part 10, a double force forming part 20, a second feeding part 30, a pressing part 40, a third feeding part 50, a conveying part 60 and A receiving part 70.

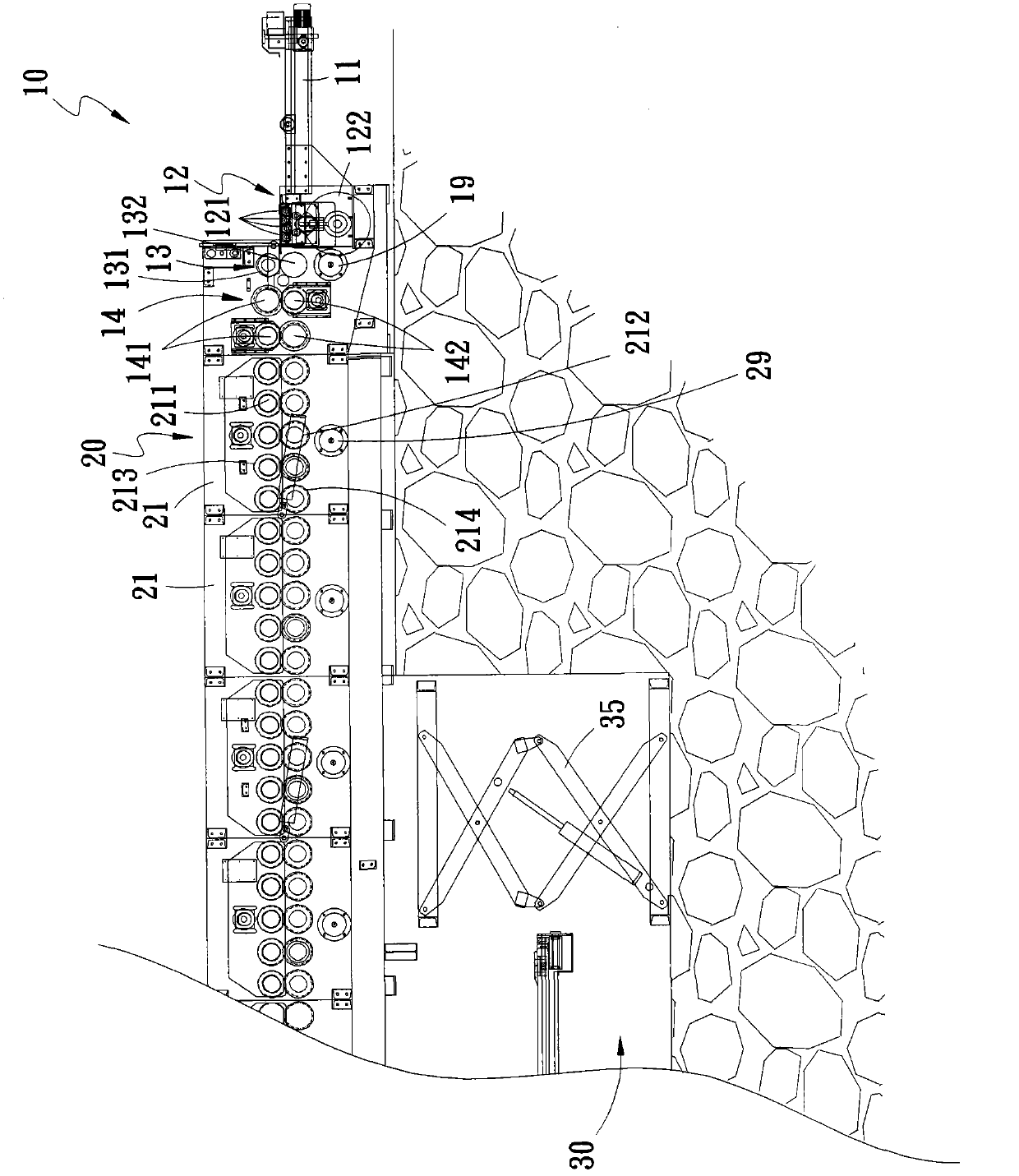

[0040] Please also refer to image 3 and Pic 4-1 , the first feeding part 10 is used to carry the first substrate 28 of corrugated cardboard, the first feeding part 10 includes a first carrier 11, a first conveying unit 12, a first feeding board Unit 13, two parallel embossing units 14 and a servo motor 19, wherein

[0041] The first end of the first conveying unit 12 is arranged at the end of the first carrier 11, and the first conveying unit 12 includes a plurality of first rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com