DI type electric chain hoist

An electric chain hoist and chain guide technology, applied in hoisting devices, spring mechanisms, etc., can solve problems such as immature safety clutch technology, unreliable limit devices, unstable load limit values, etc., and achieve force Reasonable, improve safety and reliability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

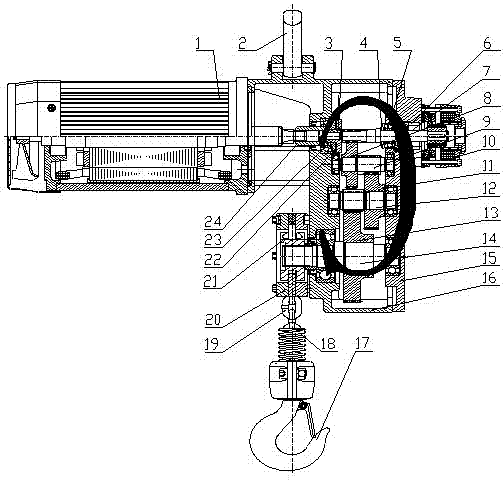

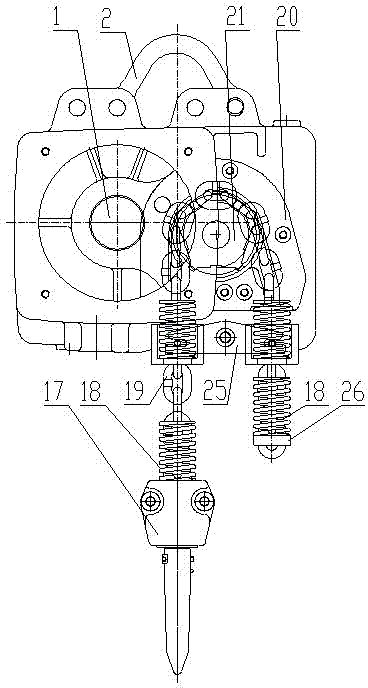

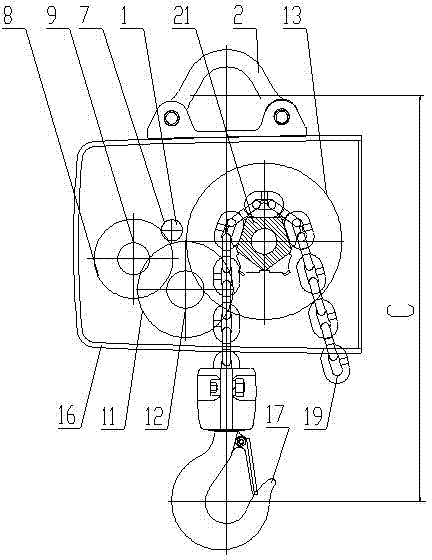

[0040] Below in conjunction with accompanying drawing, structural arrangement form, safety clutch, limit device in the present invention are further described:

[0041] attached figure 1 Transmission principle: The power of the motor 1 is transmitted to the reducer through the safety clutch 3. Three-stage gear reduction: the first-stage gear shaft 7 and the first-stage gear 8; the second-stage gear shaft 9 and the second-stage gear 11; the third-stage The gear shaft 12 and the third-stage gear 13; then passed to the output shaft 14, the output shaft 14 is equipped with a sprocket 21, the sprocket 21 has a chain eyelet groove, the rotation of the sprocket 21 drives the chain 19 to rise and fall, through The hook 17 lifts the heavy object up and down, and the orderly movement of the chain 19 is guided by the chain guide device 20 set outside the sprocket 21. The center of the motor 1 and the center of the output shaft 14 are close to the same horizontal position. Such a struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com