Composite gas hydrate accelerator and preparation method thereof

A gas hydrate and accelerator technology, which is applied in the field of gas hydrate enhanced generation technology and the application field of hydrate method, can solve the problems of slow hydrate generation rate and low gas storage density, shorten the reaction time and reduce the gas-liquid level. Tension, good gas solubilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

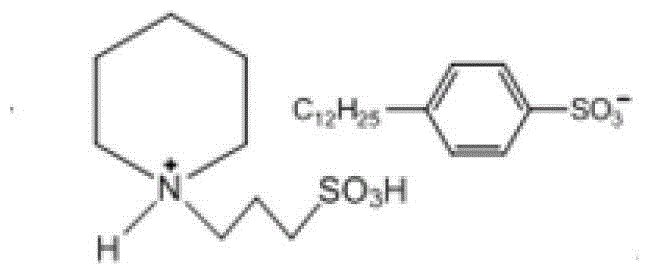

Embodiment 1

[0026] Take a certain mass concentration of 1-(3-sulfonic acid group) propylpiperidine dodecylbenzenesulfonic acid ionic liquid and APG to form a composite accelerator with a molar concentration ratio of 1:1.33 and a total molar mass fraction of 0.07%. , Take 200mL and inject it into a high-pressure magnetic dynamic stirring reactor. Set the temperature of the constant temperature water bath to 4°C, and inject CO 2 Gas, the experimental pressure is 3.5Mpa, CO begins to form at the gas-liquid interface about 1min after the gas intake ends 2 Hydrate crystal nuclei, the induction time is very short, after 6 minutes the dense hydrate layer covers the entire gas-liquid interface, at this time start stirring, the stirring speed is 400-500rpm, after 40 minutes of reaction, the hydrate is full of the reaction kettle, wait for the temperature and pressure to stabilize for half Hours later, the exhaust gas was started, and the equilibrium pressure was found to be 1.83 MPa through const...

Embodiment 2

[0028] Take a certain mass concentration of 1-(3-sulfonic acid group) propylpiperidine dodecylbenzenesulfonic acid ionic liquid and APG to form a composite accelerator with a molar concentration ratio of 1:1.67 and a total molar mass fraction of 0.24%. , Take 200mL and inject it into a high-pressure magnetic dynamic stirring reactor. Set the temperature of the constant temperature water bath to 4°C, and inject CO 2 Gas, the experimental pressure is 3.5Mpa, and CO begins to form at the gas-liquid interface about 0.5min after the gas intake ends 2 Hydrate crystal nuclei, the induction time is very short, after 7 minutes, the dense hydrate layer covers the entire gas-liquid interface, at this time start stirring, the stirring speed is 400-500rpm, after 35 minutes of reaction, the hydrate is full of the reactor, and when the temperature and pressure are stable for half Hours later, the exhaust gas was started, and the equilibrium pressure was found to be 2.34MPa by constant tempe...

Embodiment 3

[0030] Take a certain mass concentration of 1-(3-sulfonic acid group) propylpiperidine dodecylbenzenesulfonic acid ionic liquid and APG to form a composite accelerator with a molar concentration ratio of 1:1.6 and a total molar mass fraction of 0.13%. , Take 200mL and inject it into a high-pressure magnetic dynamic stirring reactor. Set the temperature of the constant temperature water bath to 4°C, and inject CO 2 Gas, the experimental pressure is 3.5Mpa, the moment the intake ends, CO begins to form at the gas-liquid interface 2Hydrate crystal nuclei, the induction time is very short, after 3.5 minutes, the dense hydrate layer covers the entire gas-liquid interface, at this time, start stirring, the stirring speed is 400-500rpm, after 20 minutes of reaction, the hydrate is full of the reactor, and the temperature and pressure are stable Half an hour later, the exhaust gas was started, and the equilibrium pressure was found to be 1.73MPa by constant temperature and pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com