Groove-type locked floor

A card slot type, floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problem of entering the joint formed by the cooperation of two ground covering boards, achieve good waterproof effect and ensure self-locking effect , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

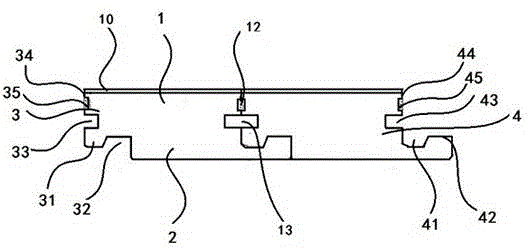

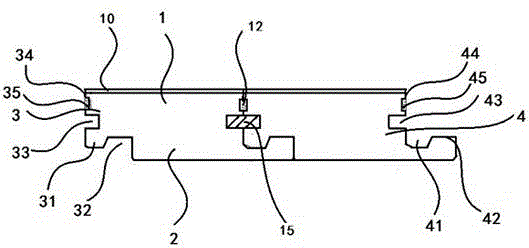

[0020] Such as Figure 1-2 As shown, the card-slot locking floor described in this embodiment includes a plurality of identical floor units, and the floor unit includes: a flat upper surface 1, and a lower surface 2 opposite to the upper surface 1, And the upper surface has a wear-resistant and water-resistant paint layer 10 with a thickness of 0.1-1.5 mm. The wear-resistant and water-resistant paint layer is formed by coating with fluorine-containing paint, and the fluorine-containing paint is composed of 15wt% Methyl etherified melamine resin, 10wt% allyl perfluoroether, 0.15wt% potassium persulfate, 3.2wt% nano-silica and the rest of isopropanol at an air pressure of 0.5 MPa and a temperature of 120°C Stirring and reacting under certain conditions for 10 hours; a first side end 3, and a second side end 4 opposite to the first side end 3, and each side end extends from between the upper surface and the lower surface; The first side end 3 has a downwardly protruding male ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com