Ultrasonic detection device for residual stress on near surface of hole or cavity

A technology of ultrasonic testing and cavities, which can be used in measuring devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., and can solve problems such as long testing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention is described in detail below:

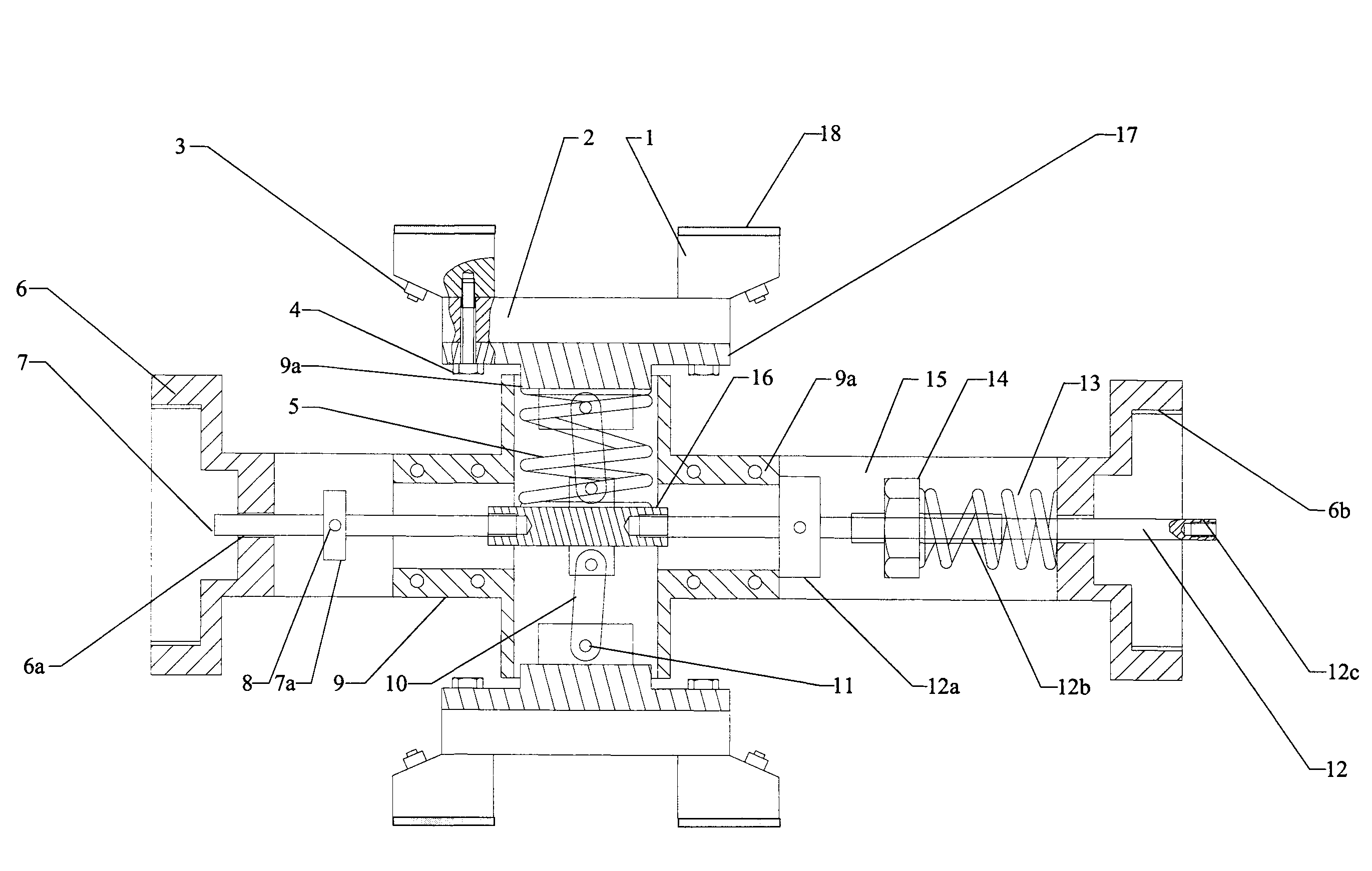

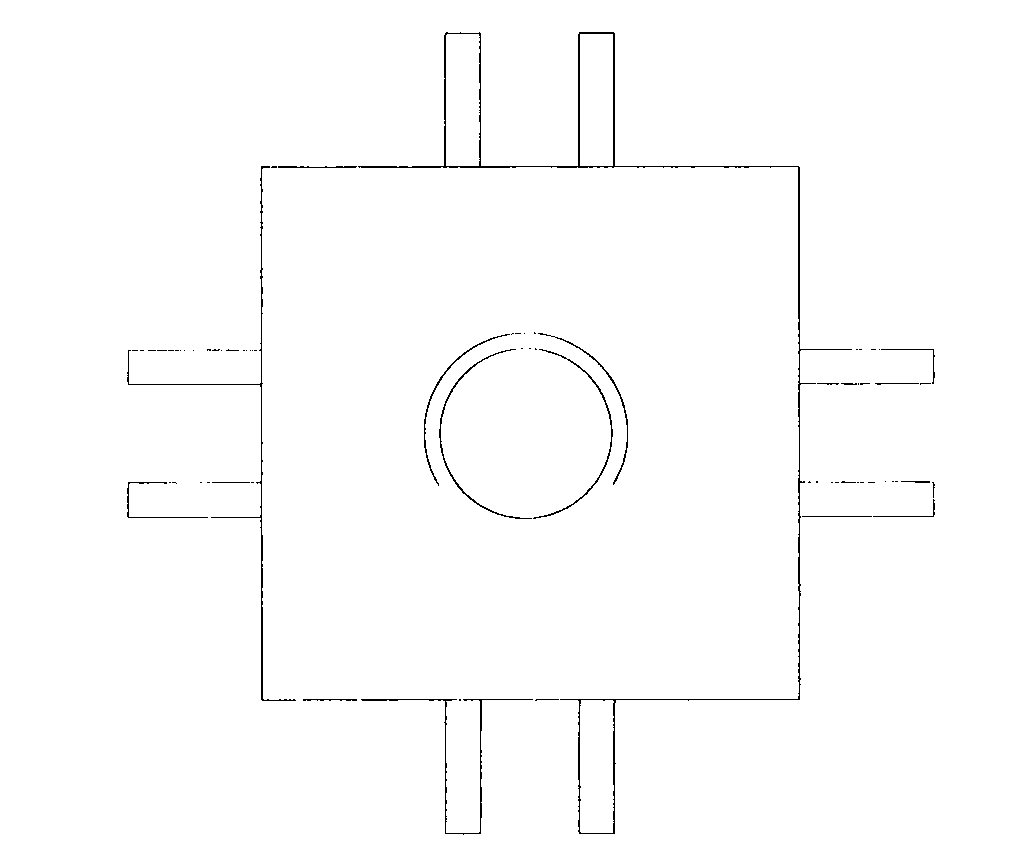

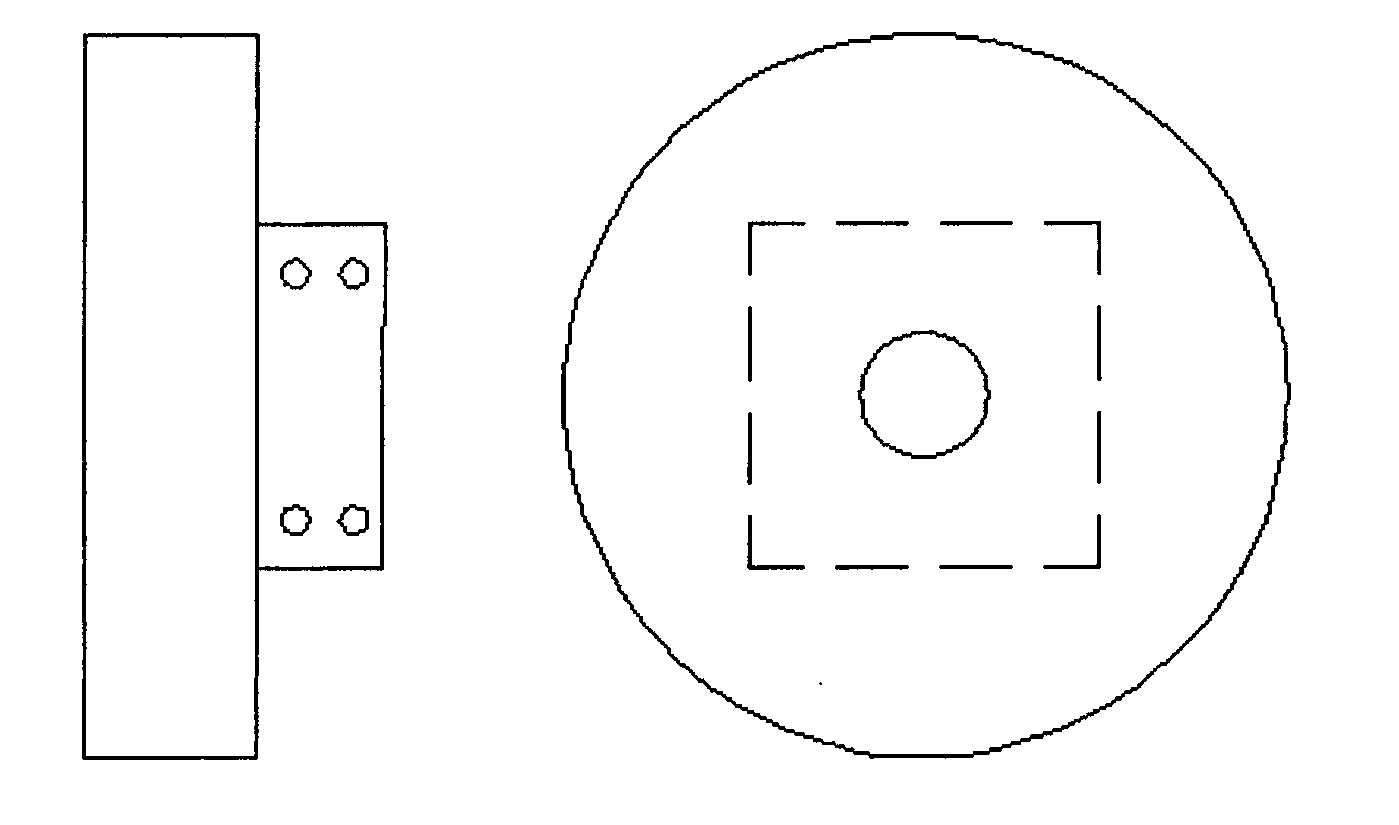

[0014] figure 1 It is a cross-sectional view of the ultrasonic detection device for internal stress of the cavity along its center line of the present invention. as it should figure 1 As shown, the ultrasonic testing device for internal stress in the cavity has 4 sets of transceiver devices (only 2 are shown in the figure), and the transceiver devices are arranged at an angle of 90°. Device 3, screw 4 and silica gel layer 18 are combined. The annular array structure can realize multi-point testing, and it is easy to obtain the circumferential distribution of axial stress. The transceiver device is in the mode of sending and receiving, and uses two ultrasonic transducers. The ultrasonic transducer 3 is fixed in the plexiglass wedge 1 through threads, and the top fixing plate 2 fixes the two plexiglass wedges together. During the stress test, the pressure between the wedge and the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com