Polyvinyl chloride insulating multi-core power cable

A power cable and polyvinyl chloride technology, which is applied in the direction of insulated cables, power cables with shielding layer/conductive layer, insulated conductors, etc., can solve the problems of increased design, poor structural stability, and easy to burn, so as to improve the service life. Improves shielding properties and prevents expansion and combustion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

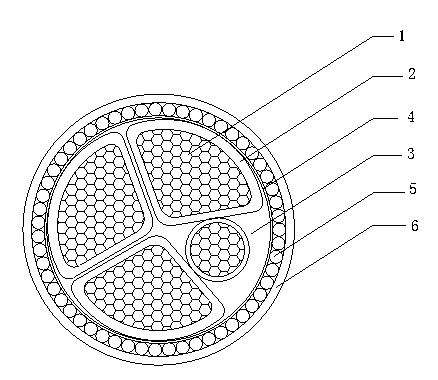

[0010] Such as figure 1 As shown, a polyvinyl chloride insulated multi-core power cable according to the present invention includes a cable core, and a filling layer 3 is arranged in the gap of the cable core, and the inner liner 4 is extruded outside the cable core, and the inner liner 4 is outer Braided armor layer 5, the outermost layer of the cable core is extruded with an outer sheath 6; the cable core is formed by twisting three fan-shaped insulated wire cores and one circular insulated wire core. The sector-shaped insulated core has the same structure as the round insulated core, and is composed of a conductor 1 and an outer insulating layer 2 covering the conductor 1 .

[0011] The aforementioned armor layer 5 is a steel wire braided structure or a steel strip structure.

[0012] There are many specific application approaches of the present invention, and the above description is only a preferred embodiment of the present invention. It should be pointed out that for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com