Degradable waterproof hot melt adhesive and preparation method thereof

A technology of hot melt adhesive and thermoplastic starch, which is applied in the direction of adhesives, adhesive types, wood fiber material adhesives, etc., and can solve problems such as inability to guarantee bonding fastness, unstable bonding force, and poor bonding strength, etc. Problems, achieve the effect of improving aging phenomenon, enhancing weather resistance and perfecting shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

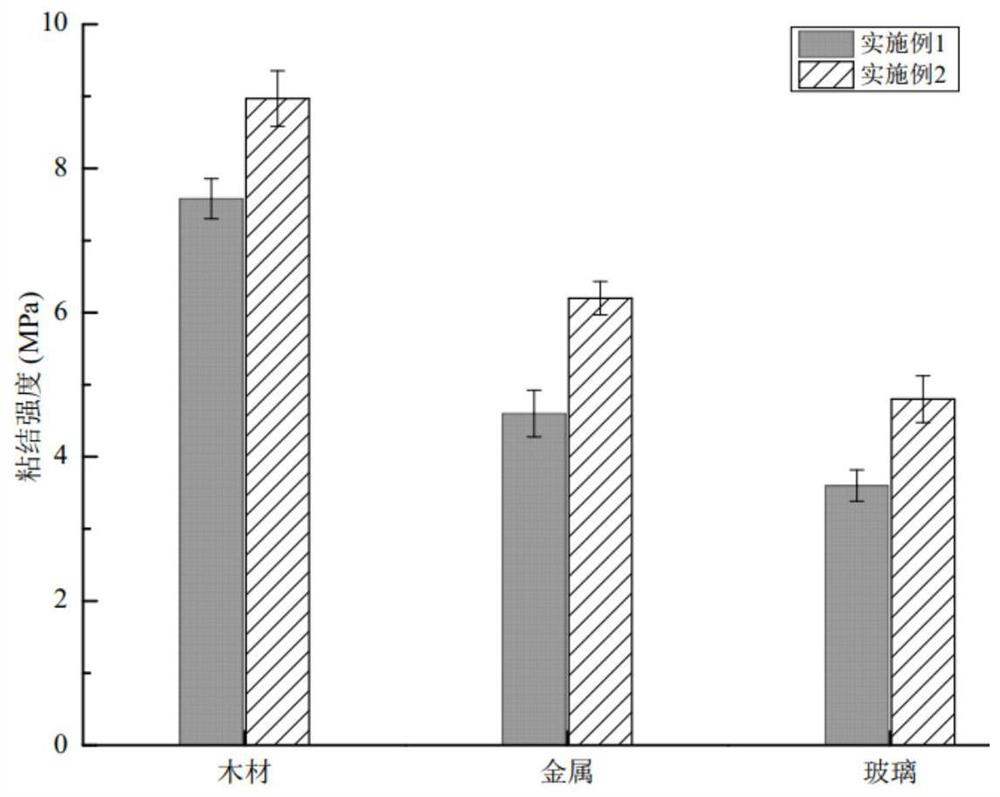

Embodiment 1

[0048] The degradable hot-melt adhesive for waterproofing comprises the following components and parts by weight: 55 parts by weight of thermoplastic starch, 35 parts by weight of benzylated plant fiber, and 110 parts by weight of polyester amide.

[0049] The preparation method of degradable waterproof hot melt adhesive comprises the following steps:

[0050] 1) According to the molar ratio of ethylene glycol: adipic acid: hexamethylenediamine = 1.15:1:0.2, take ethylene glycol, adipic acid and hexamethylenediamine and melt them in a water bath at 75°C, and then feed them with N 2 Under the conditions, start stirring and raise the temperature to 150°C, then raise the temperature to 215°C at a heating rate of 35°C / h, then add glycerol and butyl titanate to the above melting system, and stir at a rate of 300r / min for 35min, Then depressurize the reaction system to -0.1MPa, then raise the temperature to 230°C, keep constant temperature and pressure for 1.5h until the rod climbin...

Embodiment 2

[0055] The degradable hot-melt adhesive for waterproofing comprises the following components and parts by weight: 55 parts by weight of thermoplastic starch, 35 parts by weight of benzylated plant fiber, 110 parts by weight of polyester amide, 80 parts by weight of tackifying resin rosin glyceride, Viscosity modifier microcrystalline paraffin 35 parts by weight, plasticizer dioctyl phthalate 15 parts by weight, filler 10 parts by weight, antioxidant 2,6-di-tert-butyl-p-cresol 5 parts by weight. The above-mentioned fillers are nano-calcium carbonate and nano-titanium dioxide in a weight ratio of 4.5:1.

[0056] The preparation method of degradable waterproof hot melt adhesive comprises the following steps:

[0057] Step 1)-step 3), is consistent with step in embodiment 1, and difference is following steps:

[0058] 4) Put polyester amide, thermoplastic starch, tackifying resin, benzylated plant fiber, viscosity regulator, plasticizer, filler and antioxidant into the mixer by w...

Embodiment 3

[0060] The preparation method of degradable waterproof hot melt adhesive comprises the following steps:

[0061] Step 1)-step 3), is consistent with step in embodiment 2, and difference is following steps:

[0062] Step 4), first according to the weight ratio of thermoplastic starch: benzylated plant fiber = 10:6, take 55 parts by weight of thermoplastic starch and 33 parts by weight of benzylated plant fiber and add them to the mixer, then add 0.5% by weight of thermoplastic starch 2-methoxytetrahydropyran, then by weight 110 parts by weight of polyesteramide, 80 parts by weight of tackifying resin rosin glyceride, 35 parts by weight of viscosity regulator microcrystalline paraffin, plasticizer phthalic acid 15 parts by weight of dioctyl ester, 10 parts by weight of filler, and 5 parts by weight of antioxidant 2,6-di-tert-butyl-p-cresol were put into the mixer, heated to 140°C while stirring, and the stirring speed was 60r / min. The mixing time is 45 minutes; then put the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yellowness index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com