Self-assembled nanocomposite coatings for surface modification of rubber profiles and their applications

A nanocomposite coating and surface modification technology, which is applied in the direction of coating, can solve the problems of short service life and achieve the effects of long service life, low production cost, good strength and anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

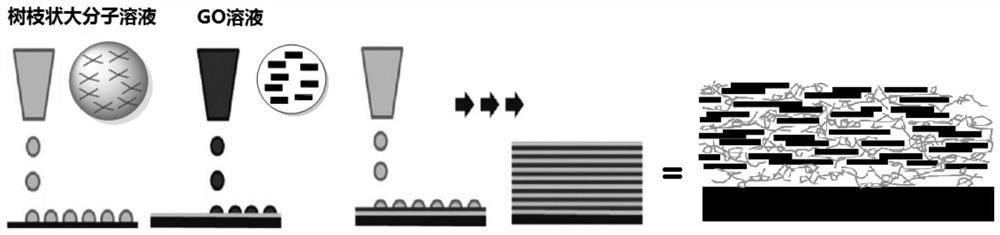

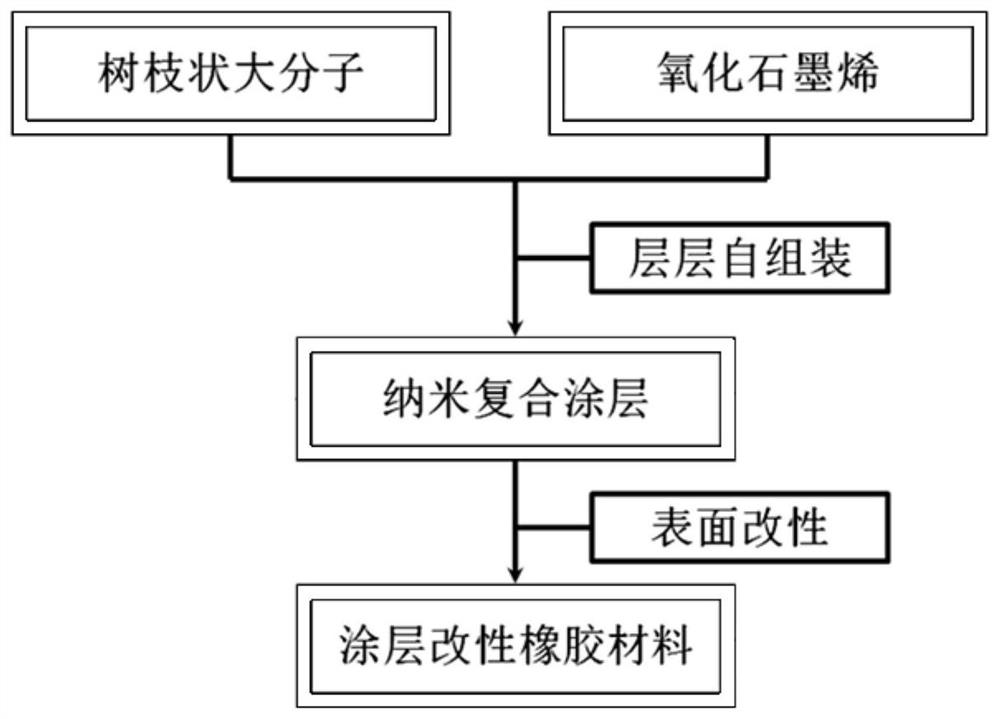

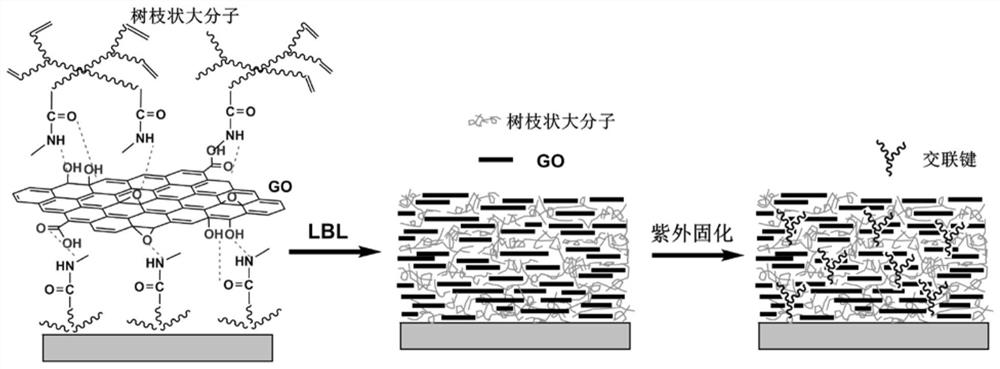

[0028] Embodiment 1 (see Figure 1-4 ):

[0029] Self-assembled nanocomposite coatings for surface modification of rubber profiles, which consist of alternate deposition of dendritic macromolecule interface layers and graphene oxide interfacial layers on the surface of rubber profiles (dendrimer / graphene oxide) n alternating interface layer.

[0030] The raw material components of the dendrimer interface layer are as follows in parts by weight: 100 parts of dendrimers, 90 parts of UV curing auxiliary materials for the dendrimer interface layer; the raw materials of the dendrimer interface layer UV curing auxiliary materials The components are as follows in parts by weight: 45 parts of methyl methacrylate, 35 parts of diluent, 4 parts of photoinitiator, and 1.5 parts of leveling agent;

[0031] The raw material components of the graphene oxide interface layer are as follows in parts by weight: 2.5 parts of graphene oxide, 2.5 parts of deionized water, 1.5 parts of graphene ox...

Embodiment 2

[0046] Self-assembled nanocomposite coatings for surface modification of rubber profiles, which consist of alternate deposition of dendritic macromolecule interface layers and graphene oxide interfacial layers on the surface of rubber profiles (dendrimer / graphene oxide) n alternating interface layer.

[0047] The raw material components of the dendrimer interface layer are as follows in parts by weight: 100 parts of dendrimers, 80 parts of UV curing auxiliary materials for the dendrimer interface layer; the raw materials of the dendrimer interface layer UV curing auxiliary materials The components are as follows in parts by weight: 45 parts of methyl methacrylate, 50 parts of diluent, 5 parts of photoinitiator, and 1 part of leveling agent;

[0048] The raw material components of the graphene oxide interface layer are as follows in parts by weight: 1 part of graphene oxide, 1 part of deionized water, 1 part of graphene oxide interface layer UV curing auxiliary material; the gr...

Embodiment 3

[0062] Self-assembled nanocomposite coatings for surface modification of rubber profiles, which consist of alternate deposition of dendritic macromolecule interface layers and graphene oxide interfacial layers on the surface of rubber profiles (dendrimer / graphene oxide) n alternating interface layer.

[0063] The raw material components of the dendrimer interface layer are as follows in parts by weight: 100 parts of dendrimers, 110 parts of UV curing auxiliary materials for the dendrimer interface layer; the raw materials of the dendrimer interface layer UV curing auxiliary materials The components are as follows in parts by weight: 75 parts of methyl methacrylate, 25 parts of diluent, 5 parts of photoinitiator, and 2 parts of leveling agent;

[0064] The raw material components of the graphene oxide interface layer are as follows in parts by weight: 1 part of graphene oxide, 2 parts of deionized water, 1.5 parts of UV curing auxiliary materials for the graphene oxide interfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com