Primer for polyurethane sealing gum and preparation method thereof

A polyurethane sealant and primer technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as difficulty in wide application and promotion, cracking and peeling of primer film, and bonding failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

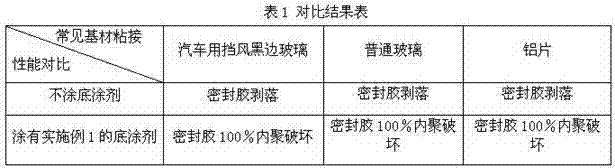

Embodiment 1

[0067] A preparation method for primer for polyurethane sealant, comprising the following steps:

[0068] Step 1, add 20 parts by mass of E-35 epoxy resin and 4 parts by mass of TDiol-400 (Tianjin No. water for 3 hours, then add 6 parts by mass of toluene diisocyanate to the reactor, mix well, adjust the temperature of the reactor to 65°C, and react for 2 hours, then add 0.05 parts by mass of dibutyltin dilaurate to the reactor, continue React for 1h to obtain the first mixed solution;

[0069] Step 2, measure the weight percent content of the isocyanate group in the first mixed solution to be 4.9%, keep the temperature in the reactor constant, and add 68 parts by mass of ethyl acetate and 0.5 parts by mass of ethyl acetate after drying and dewatering Dispersible carbon black, obtains the second mixed solution;

[0070] Step 3, the second mixed solution is input into the ball mill through the pipeline, and the circular grinding is carried out for 3 hours. During the grinding...

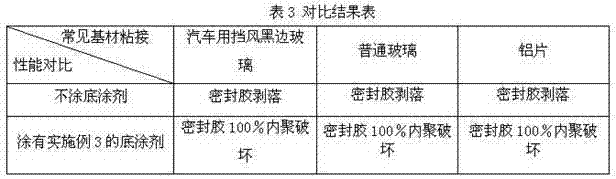

Embodiment 2

[0075] Step 1: Add 24 parts by mass of E-51 epoxy resin and 3.9 parts by mass of TDiol-700 (Tianjin No. water for 3 hours, then add 5.5 parts by mass of diphenylmethane-4,4'-diisocyanate into the reactor, mix well, adjust the temperature of the reactor to 70°C, and react for 2.5 hours, then add 0.03 The stannous octoate of mass parts continues reaction 1.5h, obtains the first mixed solution;

[0076] Step 2, measure the weight percent content of the isocyanate group in the first mixed solution to be 2.5%, keep the temperature in the reactor constant, and add 65 parts by mass of ethyl acetate and 1.5 parts by mass of ethyl acetate after drying and dewatering Dispersible carbon black, obtains the second mixed solution;

[0077] Step 3, the second mixed solution is input into the colloid mill through the pipeline, and the circular grinding is carried out for 4 hours. During the grinding process, high-purity nitrogen is used for protection, and then 0.15 mass parts of UV-320 and ...

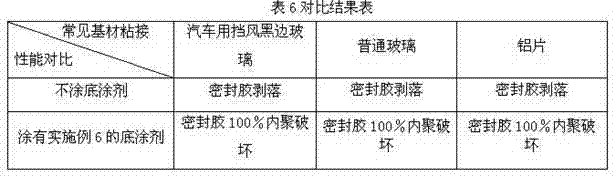

Embodiment 3

[0082] Step 1, add 20 mass parts of E-44 epoxy resin, 3.5 mass parts of TDiol-700 (Tianjin No.3 Petrochemical), 1.5 mass parts of TMN-700 (Tianjin No.3 Petrochemical) to the reactor to adjust The temperature is 90°C, the vacuum degree is not lower than 0.095, water is removed for 2.5 hours, and 5.5 parts by mass of diphenylmethane-4,4'-diisocyanate is added to the reaction kettle, and the temperature of the reaction kettle is adjusted to After reacting for 3 hours at 75°C, add 0.1 parts by mass of dibutyltin dilaurate to the reactor, and continue the reaction for 1 hour to obtain the first mixed solution;

[0083] Step 2, measure the weight percent content of the isocyanate group in the first mixed solution to be 5.4%, keep the temperature in the reactor constant, and add 70 parts by mass of acetone and butyl acetate, and 2 parts by mass of After the highly dispersible carbon black, obtain the second mixed solution;

[0084] Step 3, the second mixed solution is input into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com