Holographic ultrasonic field self-forming additive manufacturing method and device

An additive manufacturing and self-forming technology, applied in the field of holographic ultrasonic field self-forming additive manufacturing, can solve the problems of easy bonding and printing of cured photosensitive resin, failure, slow replenishment of liquid photosensitive resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

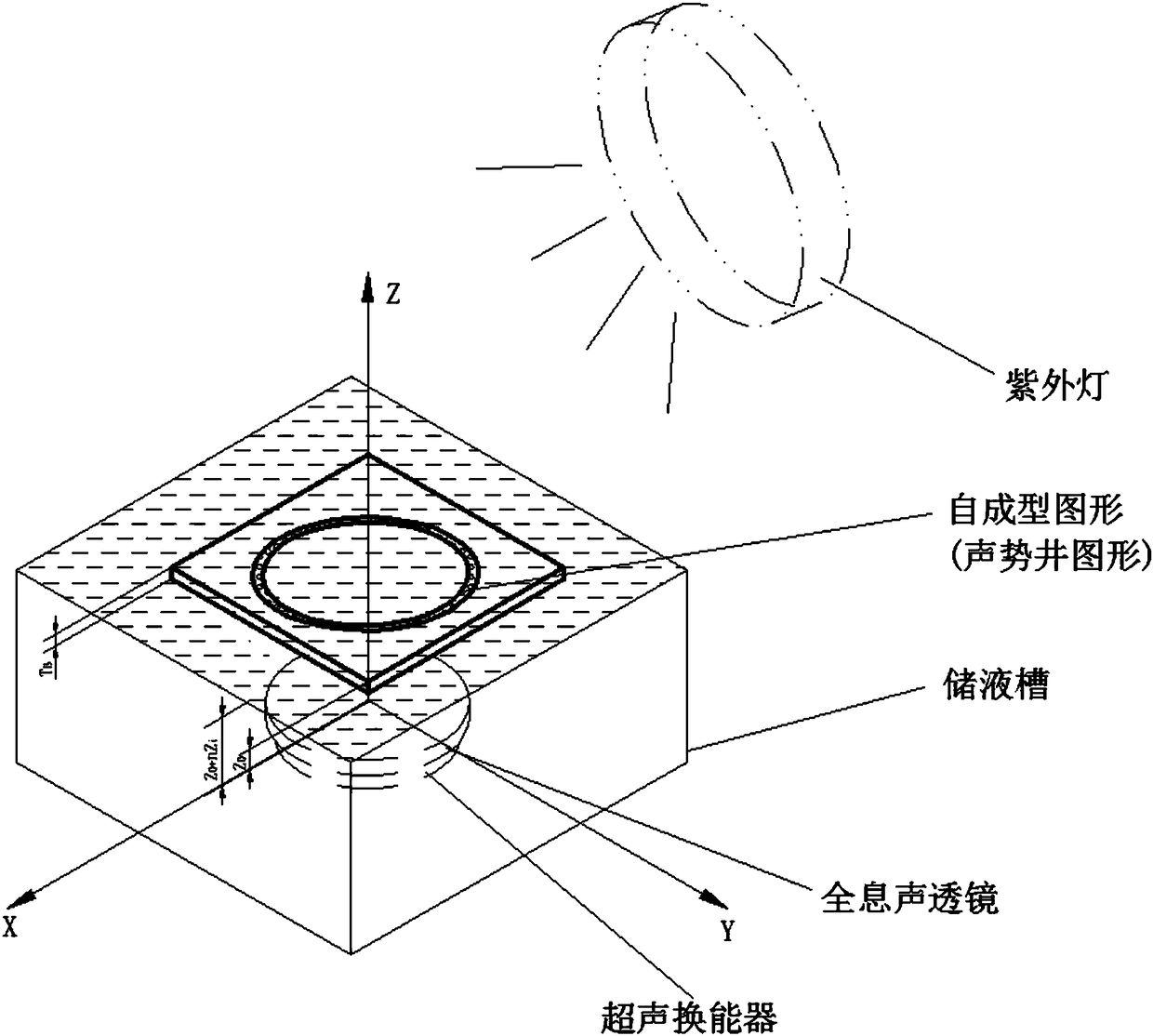

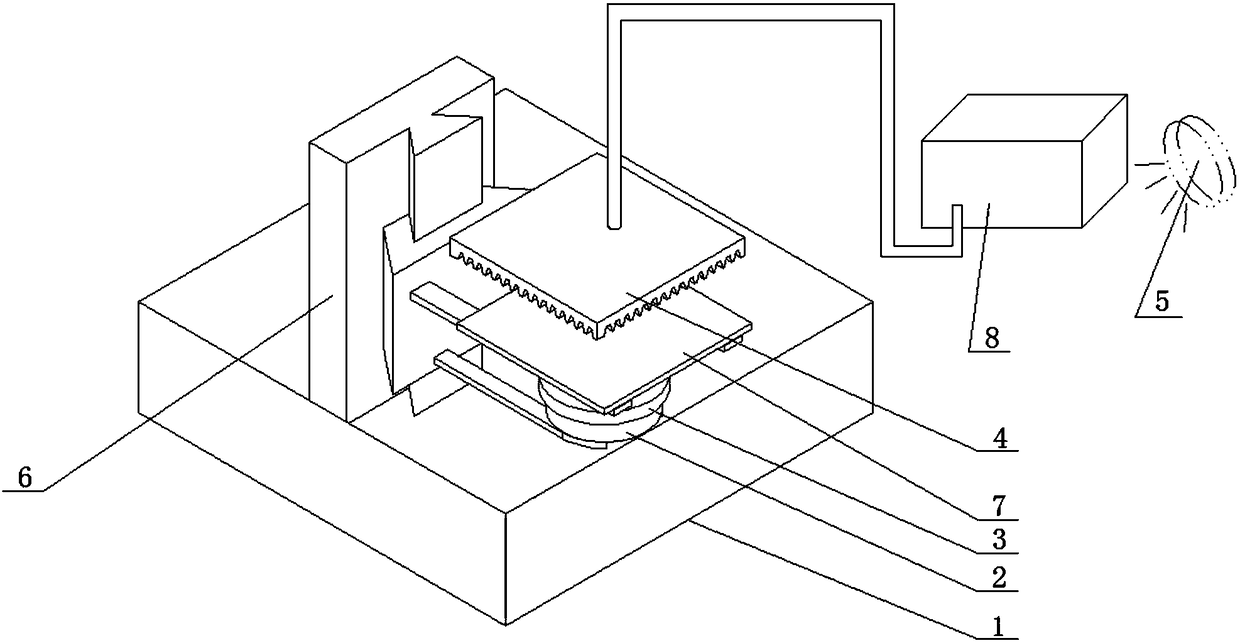

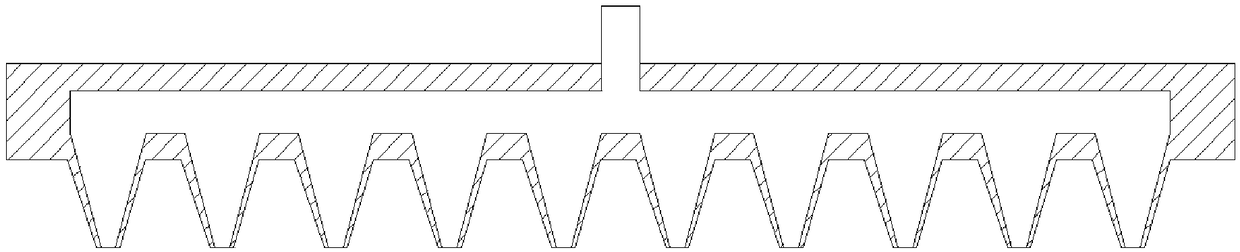

[0066] The invention is a self-forming additive manufacturing method for a holographic ultrasonic field, which uses common liquid resins as raw materials and combines photoinitiators to realize the polymerization and curing of common liquid resins. The ultrasound generated by the ultrasonic transducer can create a precise spatial ultrasonic field in space through the holographic acoustic lens. Each plane in the precise spatial ultrasonic field has a large number of acoustic potential wells, and the same plane acoustic potential wells constitute a target two-dimensional figure, the acoustic potential wells Capture the photoinitiator sprayed around, gather the surrounding ordinary liquid resin at the same time, realize the polymerization and curing of the surrounding ordinary liquid resin triggered by the photoinitiator through ultraviolet light irradiation, and complete the curing of a single plane; change the ultrasonic transducer holographic acoustic lens to the liquid surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com