Method and apparatus for the production of a metallic reel for spinning machines and reel for spinning machines thus obtained

A spinning machine and equipment technology, which is applied in the field of producing yarn bobbins for spinning machines, can solve problems affecting the cost of a single unit, and achieve the effect of ensuring axial alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

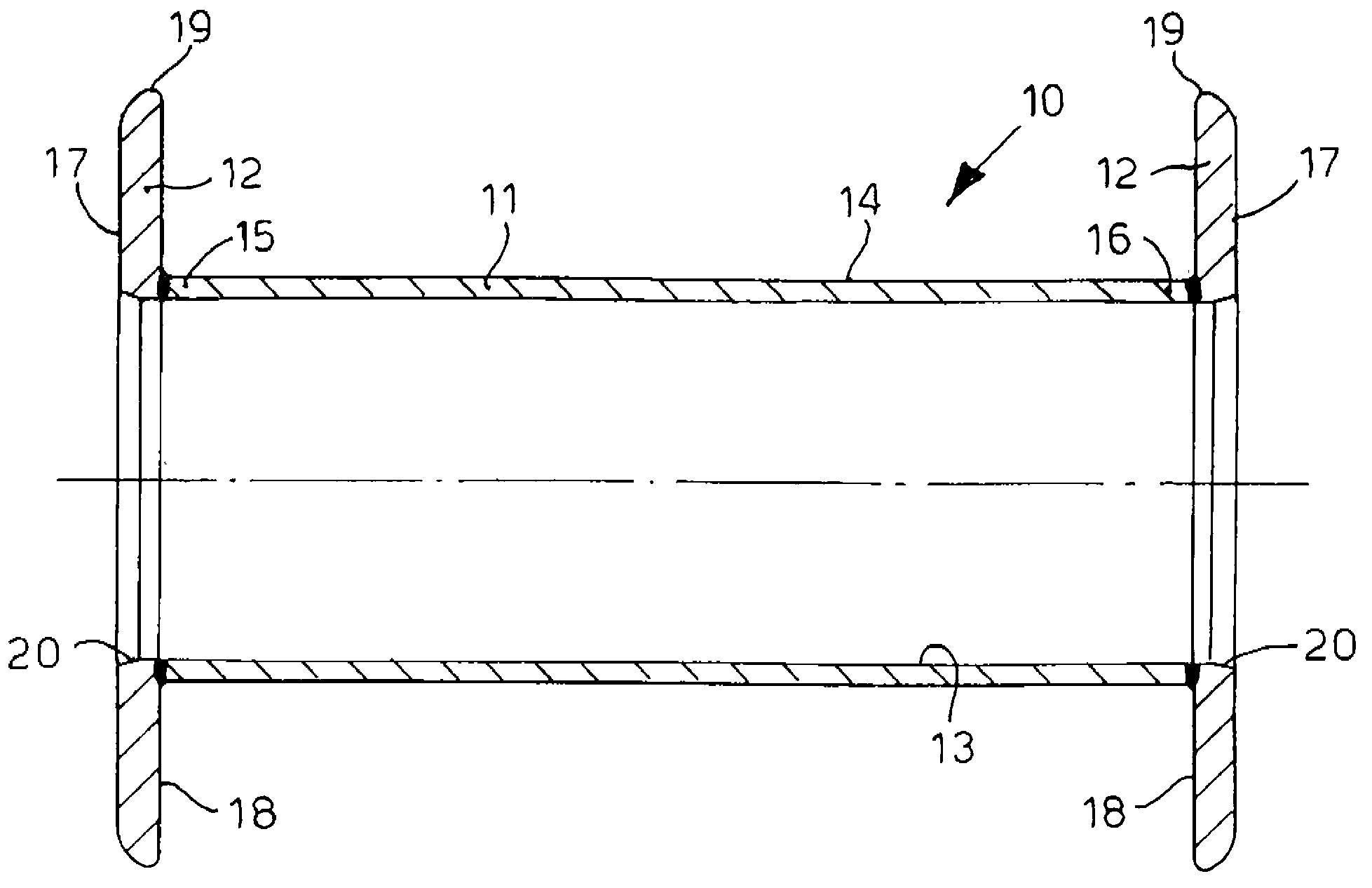

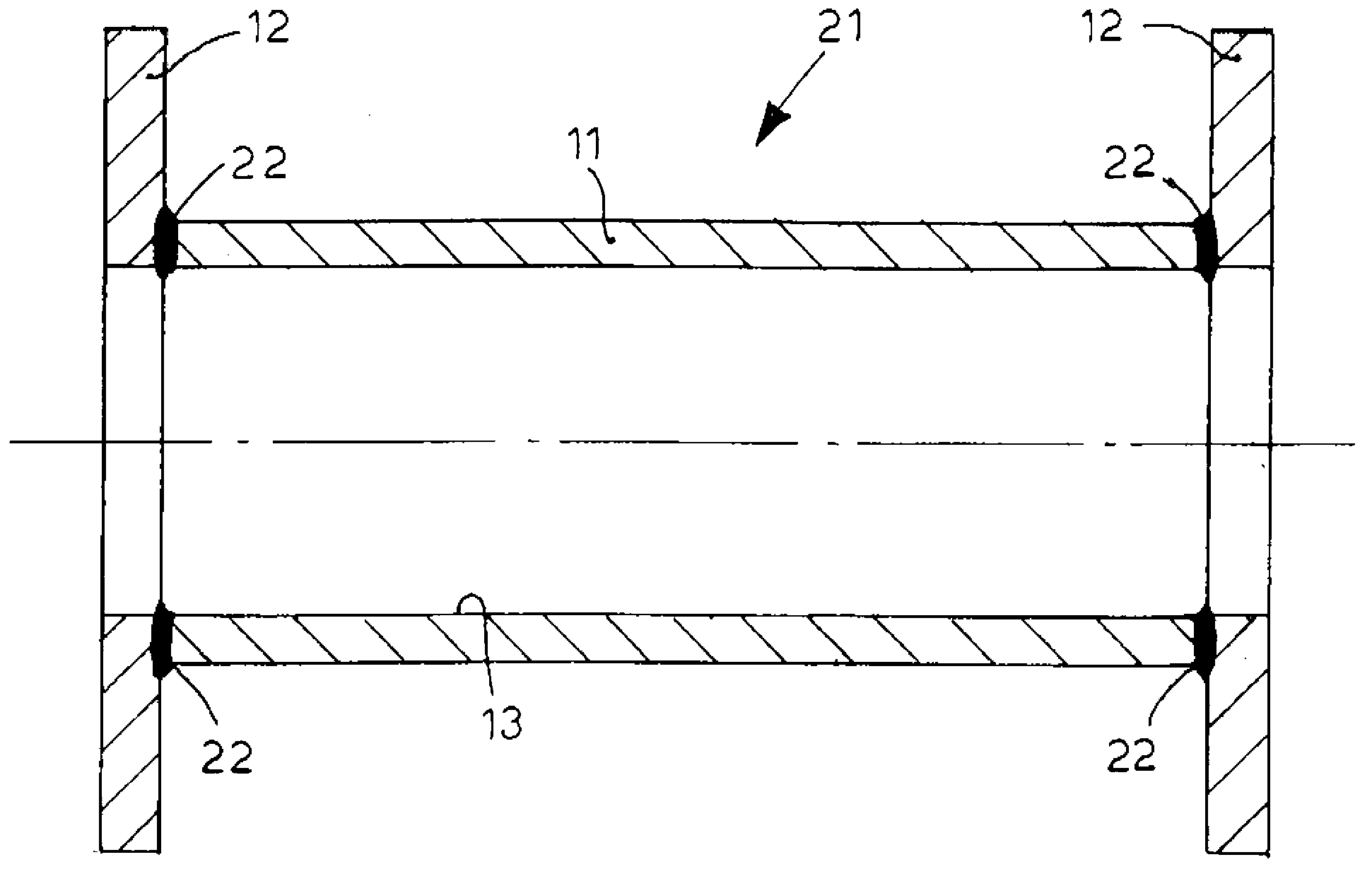

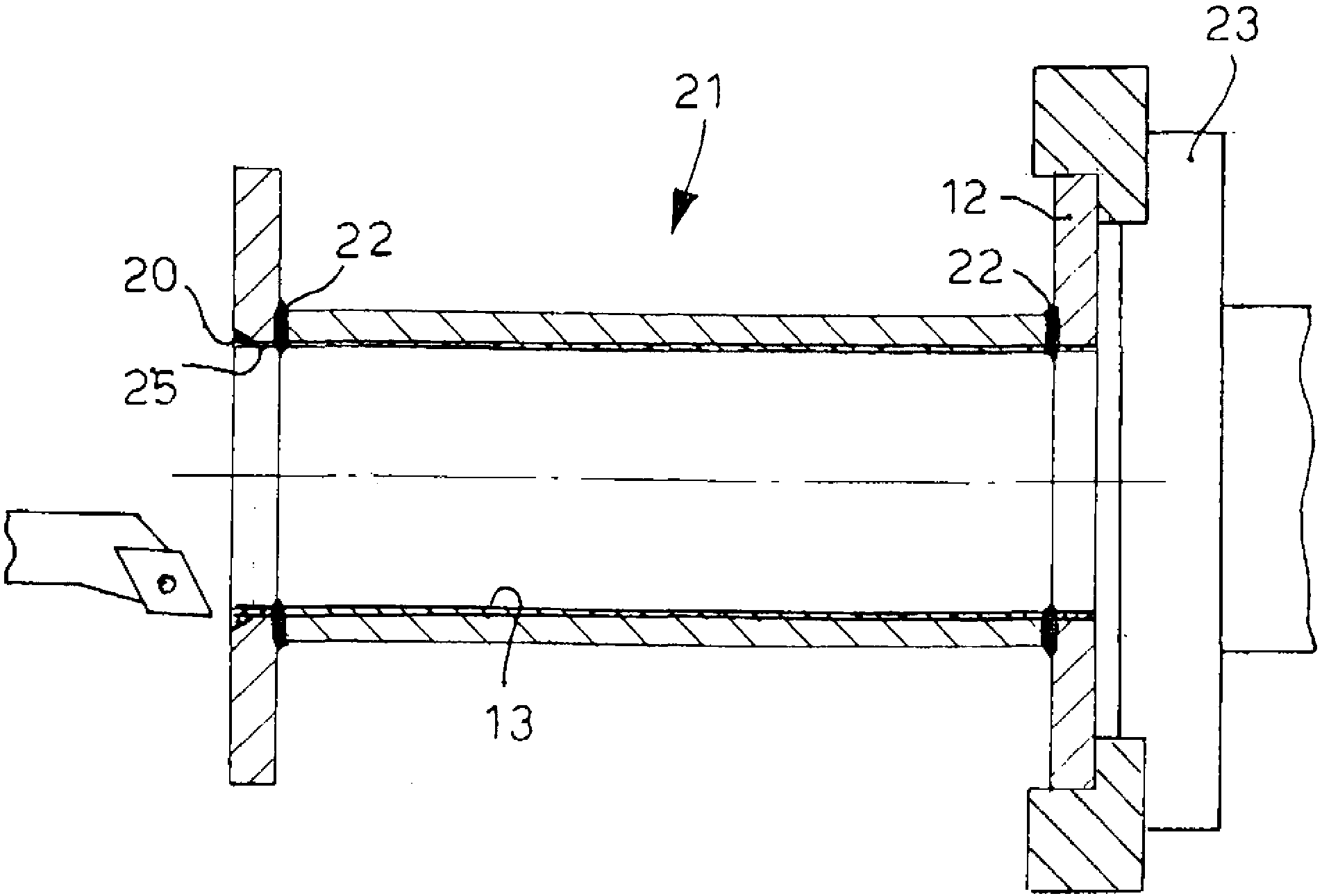

[0046] refer to figure 1 , which shows a bobbin for a spinning machine, indicated generally by reference numeral 10 , in the form completed by the method of the invention.

[0047] In particular, the bobbin 10 comprises a cylindrical body 11 and two flanges 12 coupled to respective ends 15 and 16 of the cylindrical body 11 by friction welding.

[0048] Both the cylindrical body 11 and the flange 12 are made of metallic material (in this embodiment aluminum alloy) in order to guarantee an optimal compromise between mechanical resistance and lightness.

[0049] The cylindrical body 11 is generally tubular and has an outer surface 14 onto which the yarn is wound in use.

[0050] The flange 12 is substantially disc-shaped and is axially perforated after friction welding to have the same inner diameter as the cylindrical body 11 so as to define a through hole 13 in which the spindle of the spinning wheel is housed in use .

[0051] The flanges 12 are connected in the circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com