High manganese containing steels for oil gas and petrochemical applications

A chemical, petroleum technology that is used in the application field of steel for oil, gas and petrochemical applications, which can solve problems such as pipe abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] All numerical values in the detailed description and claims herein are modified by "about" or "close to" the indicated value, and take into account experimental errors and deviations that would be expected by those of ordinary skill in the art.

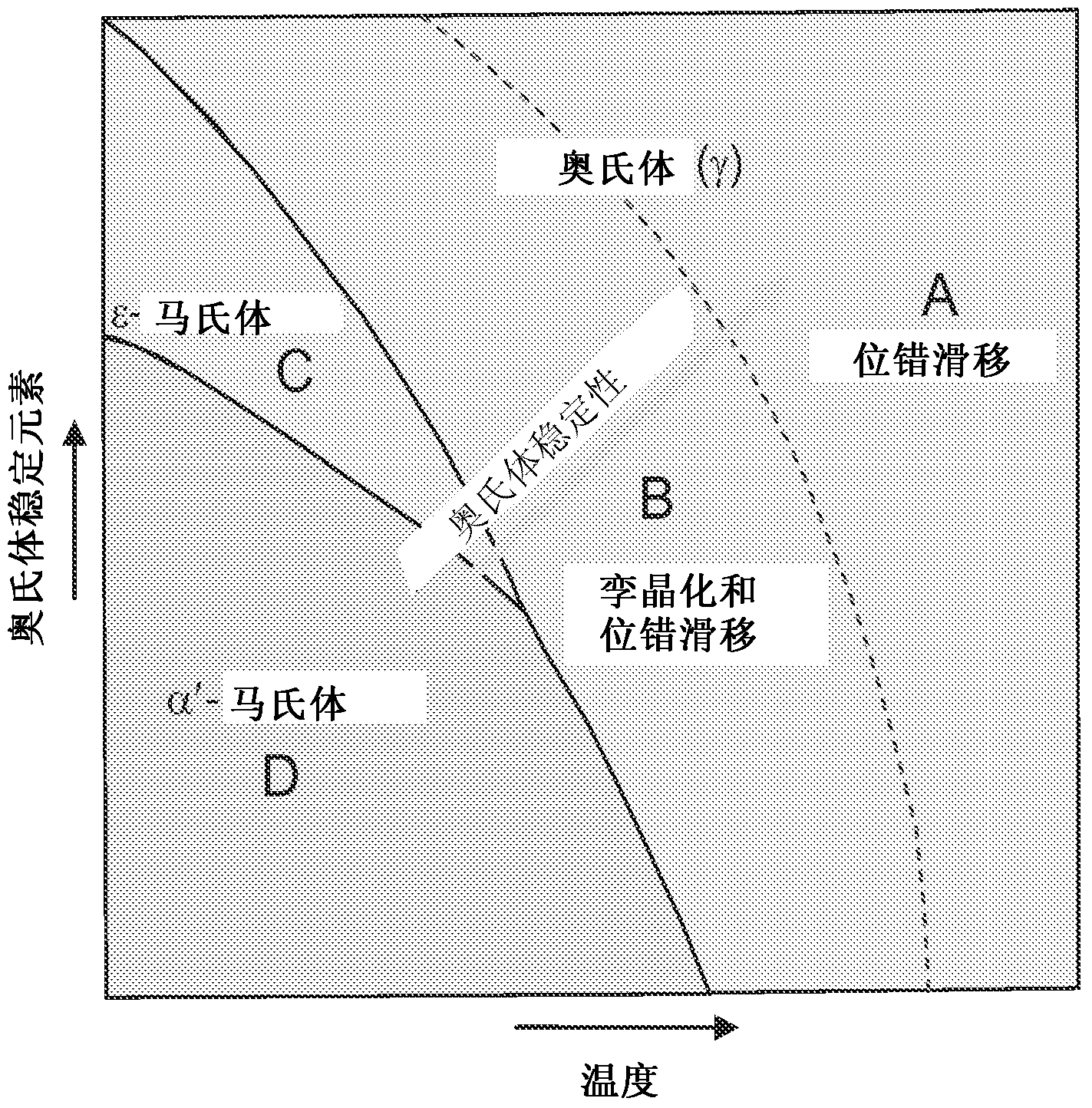

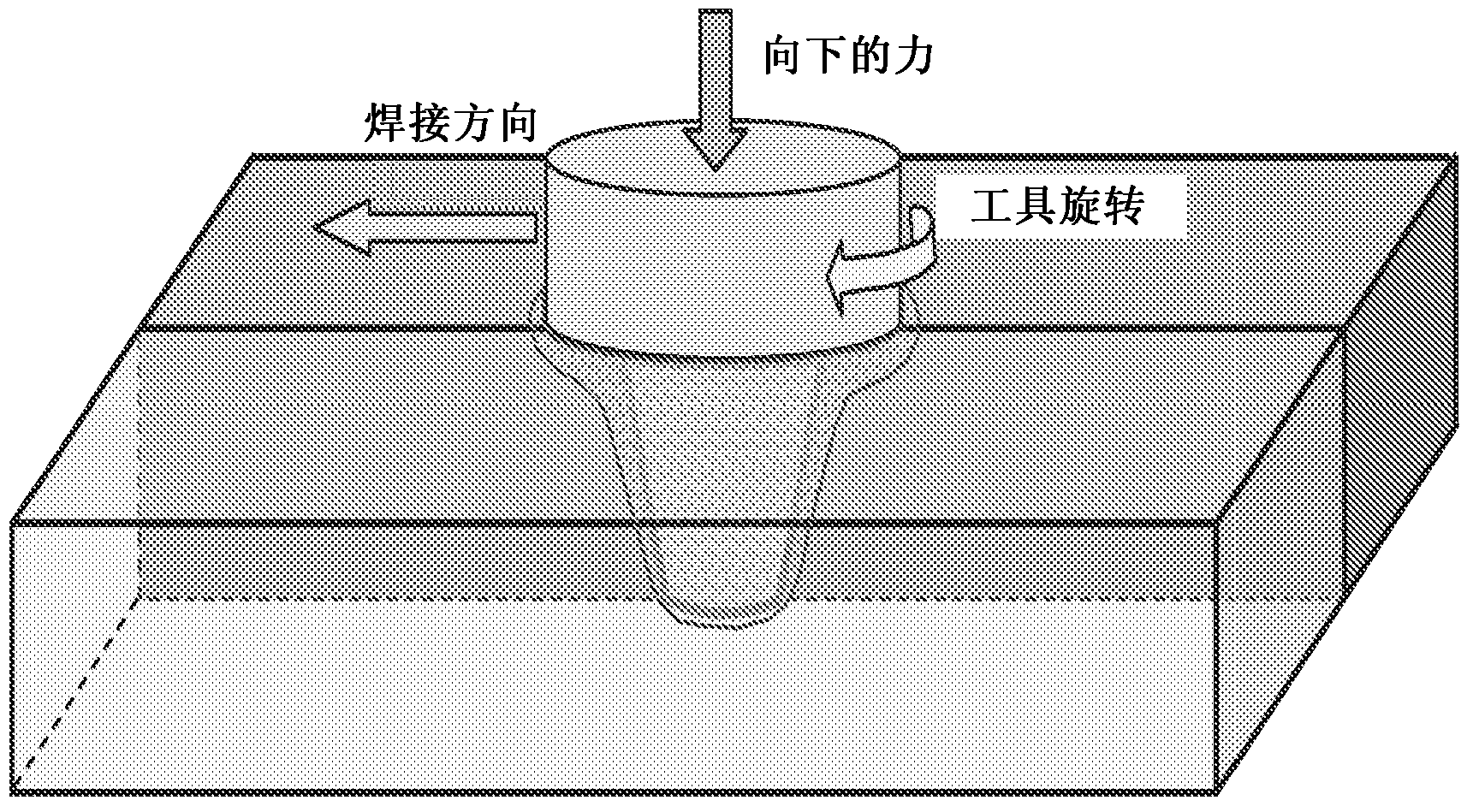

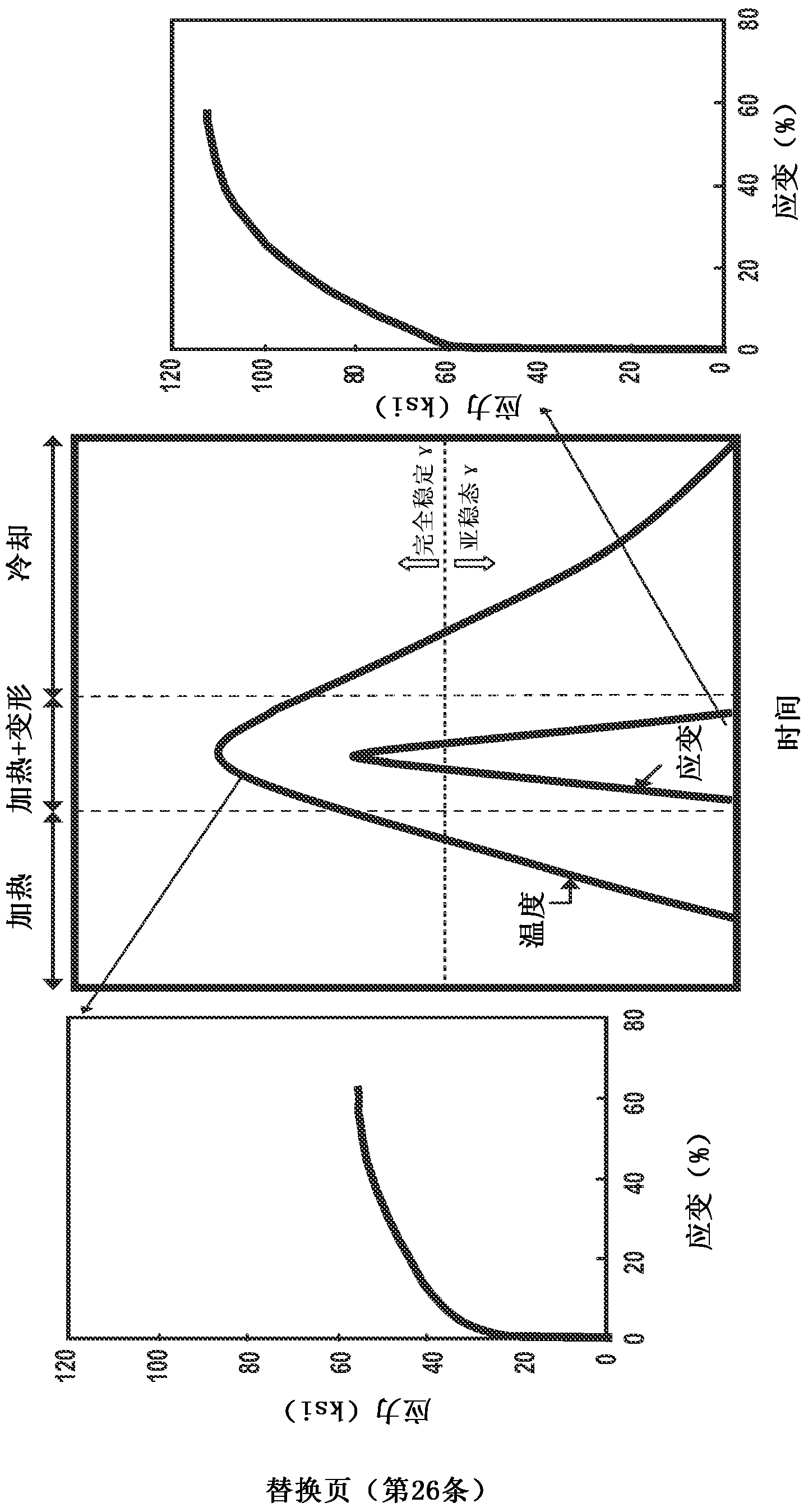

[0065] The present invention relates to high manganese containing iron components and the use of such high manganese containing iron components in steels for oil and gas exploration, production, transportation and petrochemical applications for increasing operational reliability and productivity. More particularly, applicants have discovered that in oil and gas exploration, production, transportation, and petrochemical applications, the high manganese-containing iron components improve one or more of the following properties: ductility, crack resistance, Abrasion resistance, fatigue life, surface hardness, stress corrosion resistance, fatigue resistance, and environmental cracking resistance.

[0066] Composition of compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com