Drive device for a self-propelled machine and corresponding method

A driving device and machine technology, applied in transmission, fluid transmission, transmission control, etc., can solve the problems of driving device installation space requirements, increased manufacturing cost, large size of multi-disc clutch, etc., and achieve the effect of improving life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

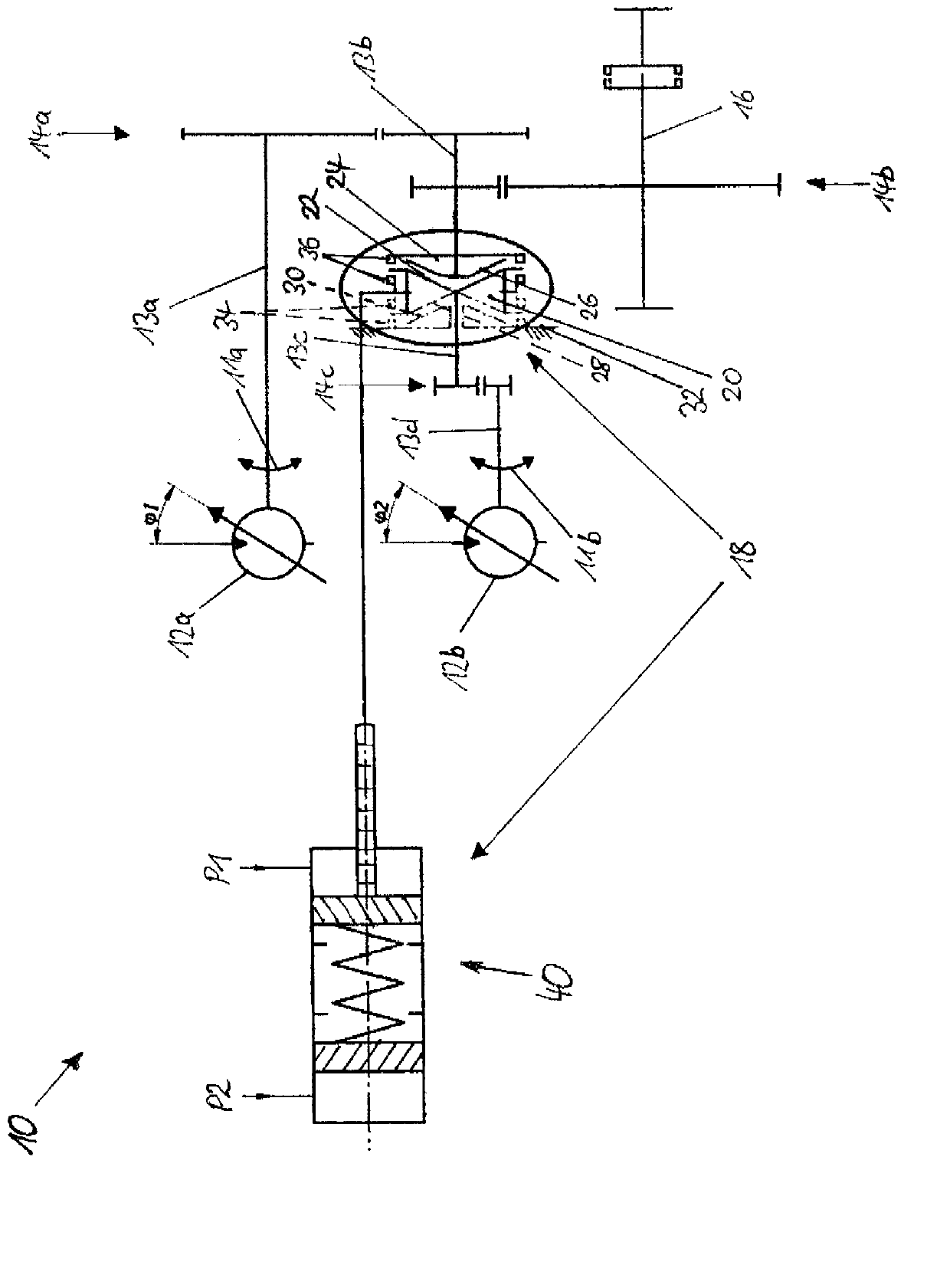

[0037] figure 1 A schematic representation of a drive device 10 according to the invention is shown for a land-based automotive processing machine (not shown). The drive device 10 comprises a first hydraulic motor 12a which can be driven by hydraulic fluid and which is coupled to a driven shaft 16 via a shaft 13a, a gear pair 14a, a shaft 13b and a gear pair 14b. Furthermore, the drive device 10 comprises a second hydraulic motor 12b, which can be driven by hydraulic fluid, and a coupling device 18, via which the second hydraulic motor 12b can be connected to the driven Shaft 16 is coupled for torque boost and is disengageable from driven shaft 16 in the second shift state. The hydraulic motor 12a has a working range which does not allow covering the entire drive range of the high-traction processing machine from low to very high travel speeds. Therefore, the first hydraulic electric motor 12 a is provided for higher speeds and lower tractive forces and is permanently couple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com