Heating element comprising films

A heating element, thin layer technology, applied in electrical elements, ohmic resistance heating, transparent/reflective heating devices, etc., can solve complex and expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

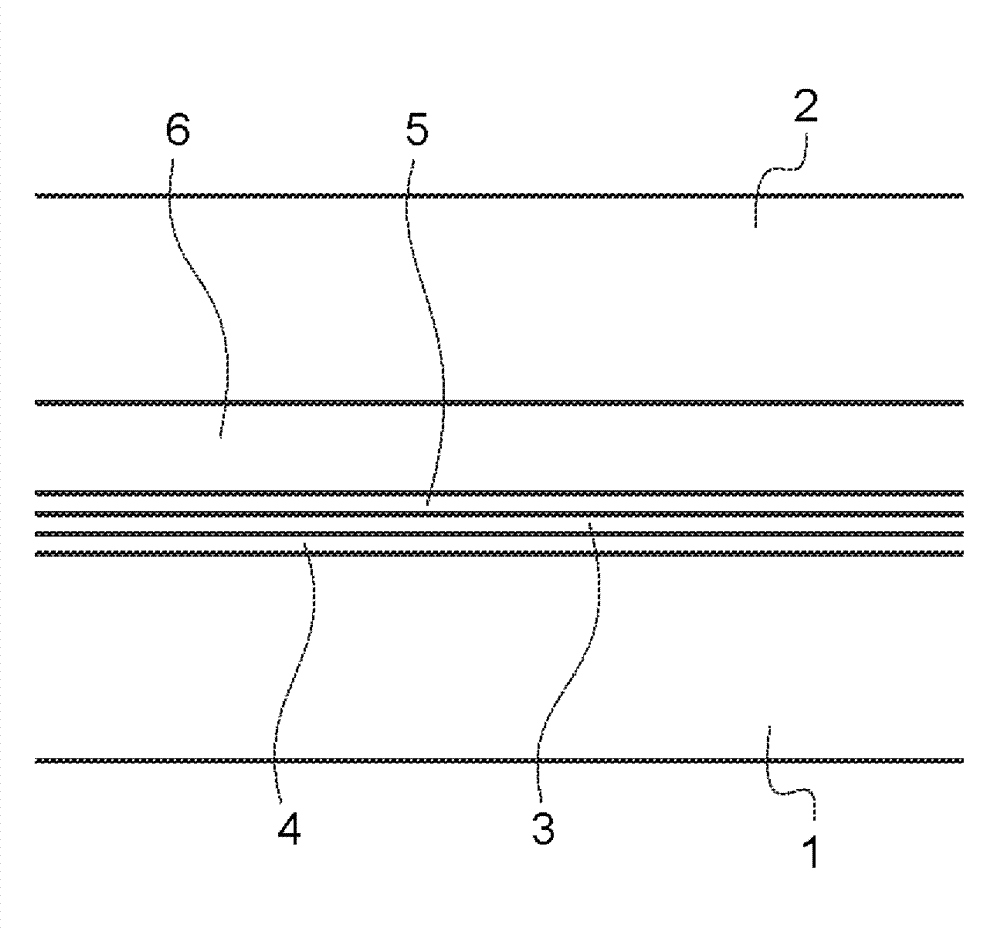

[0027] The invention relates to a heating element comprising at least one substrate equipped with a thin layer stack comprising layers suitable for heating. The layer suitable for heating has an electrical sheet resistance of between 20 and 200 ohms per square unit. A layer suitable for heating allows the glazing to be defogged / deiced or the room to be heated. The stack also includes two non-metallic dielectric layers on either side of the layer suitable for heating. These non-metallic dielectric layers have an anti-reflection function. The heating element also includes two conductive current collectors adapted to receive an electrical voltage, to which the layer adapted to be heated is electrically connected to be heated. The layer suitable for heating is intact, ie it has not been processed by etching. Consequently, no areas are removed from this layer, and no geometrical features are etched in the layer suitable for heating, which would increase the effective resistance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com