Conductive polymer-based soil deformation monitoring system and method

A conductive polymer and soil deformation technology, which can be used in basic structure tests, basic structure engineering, construction, etc., can solve the significant effects that cannot reflect the stability of geosynthetics structures, the lack of pertinence in calculation methods, and the impact of popularization and technological development to achieve the effect of reducing the risk of soil damage, low cost and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] Example 1: Subgrade 1 deformation monitoring

[0047] During road construction, in order to ensure the stability of the subgrade 1 , reinforcement measures are generally adopted, that is, the method of reinforcing soil is used to protect the overall stability of the subgrade 1 .

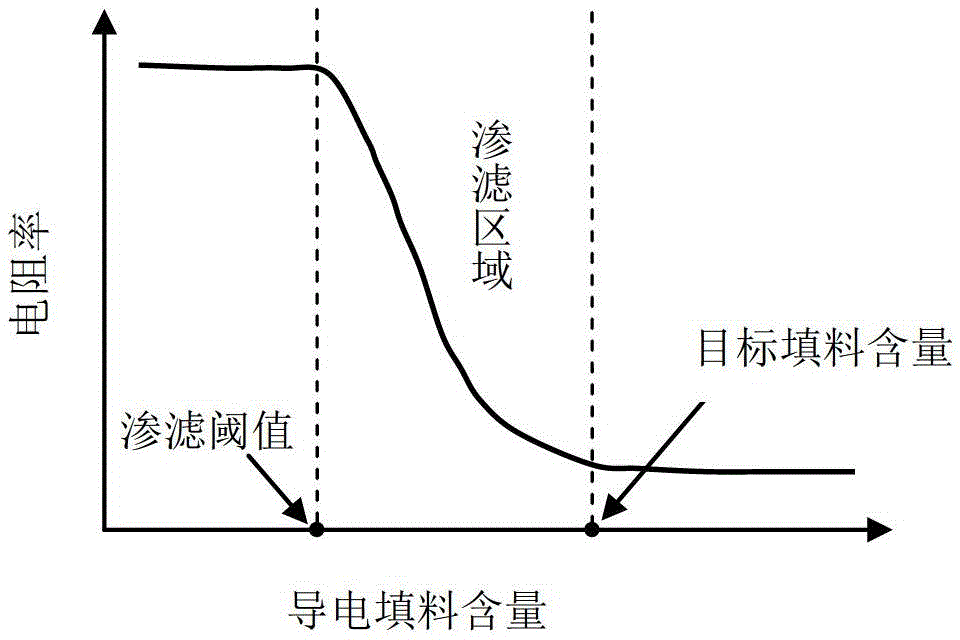

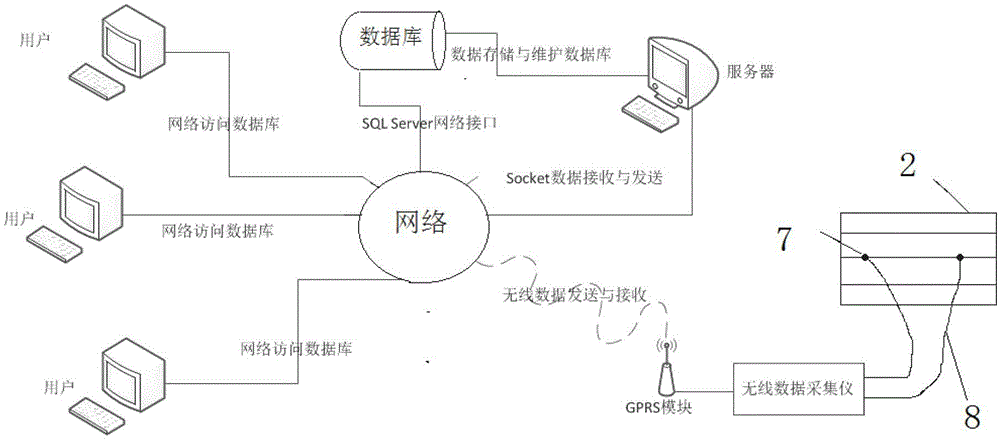

[0048] like image 3 As shown, according to the actual situation of the project, carbon black will be used as the filler (the relationship between resistivity and strain is The conductive polymer 2 reinforcement material is laid into the subgrade 1 . In order to make the conductive polymer 2 effective, several layers can be laid. Each laying layer needs to be compacted together with the roadbed 2, select a suitable number of measuring points on each layer of conductive polymer 2, connect firmly with the wire 8 and lead the wire 8 out. After the subgrade 1 project is completed, the reinforcement 3 and the soil are deformed with time, so the deformation monitoring is carried out in a fixed pe...

example 2

[0049] Example 2: Deformation Monitoring of Reinforced Retaining Wall

[0050] like Figure 4 As shown, in the construction of the retaining wall, in order to ensure its stability, multiple layers of carbon nanotubes are laid inside the wall (the relationship between resistivity and strain is For the reinforcing material of the conductive polymer 2 of the filler, an appropriate number of measuring points is selected on each layer of the conductive polymer 2 , connected firmly with the wire 8 and the wire 8 is led out. A foot guard 5 is provided near the wall 4, and the wall 4 is set on the foundation 6. When the soil deforms, the reinforcement 3 also deforms thereupon, and at the same time gives the soil a counter force to reduce the force of the wall 4. Deformation to ensure its stability. After the deformation of the reinforcement 3, the resistivity changes, and the resistance at the tensioned place increases. The monitoring personnel conduct real-time monitoring through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com