Ground machine super jar

A jar and mechanical technology, applied in wellbore/well components, earthwork drilling, etc., to achieve the effect of improving time efficiency, eliminating stuck pipe accidents, and speeding up progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

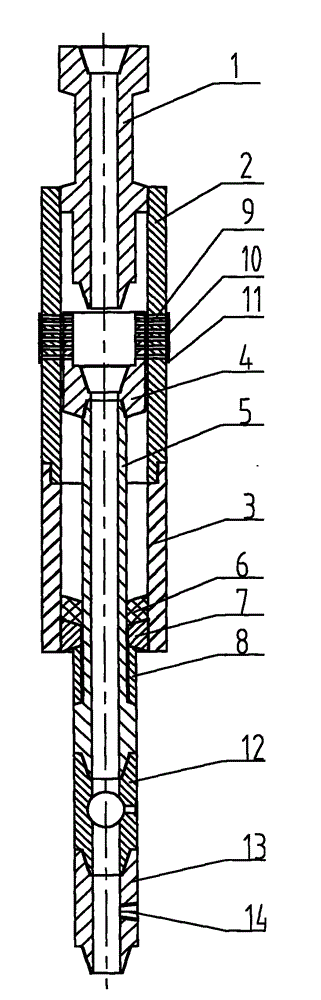

[0011] Such as figure 1 As shown, a ground mechanical super jar is mainly composed of a lifting nipple 1, an upper outer cylinder 2, a lower outer cylinder 3, a shear joint 4, a lower rod 5, a buffer pad 6, a support ring 7, and a pin alignment Backing ring 8, shear pin 9, pin protective sleeve 10, sheath retaining ring 11, lower cock 12, circulation joint 13, circulation hole 14, the lower stroke rod 5 and the shear joint 4 are connected with screws, mutually Before connecting, put the support ring 7 and the buffer pad 6 on the lower hammer 5, connect the lower hammer 5 and the shear joint 4, and the shear joint 4 has six pins that can penetrate the shear pins 9 of different diameters Hole for connecting the screw thread of the lifting nipple 1 and the upper outer cylinder 2, a section of the body that can enter the shear joint 4 protrudes from the bottom of the connecting thread of the lifting nipple 1, and the lower end of the body can be connected with the shear joint 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com