Variable high-temperature high-pressure visual rock core model holding device

A high-temperature, high-pressure, core model technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of inconvenient model installation, non-adjustable distance, and single applicable model, so as to improve the simulation degree and application range , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

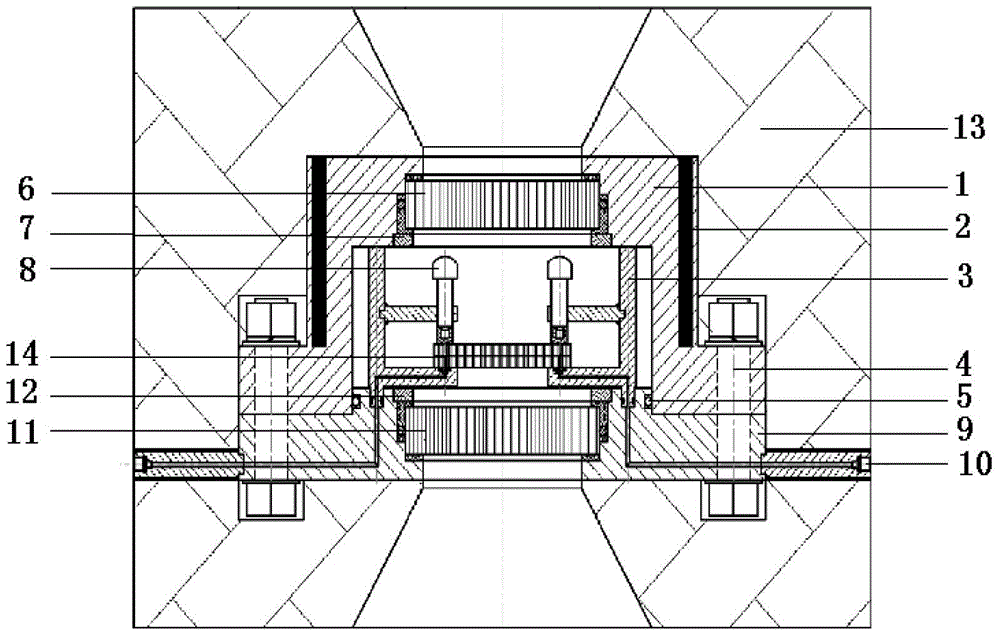

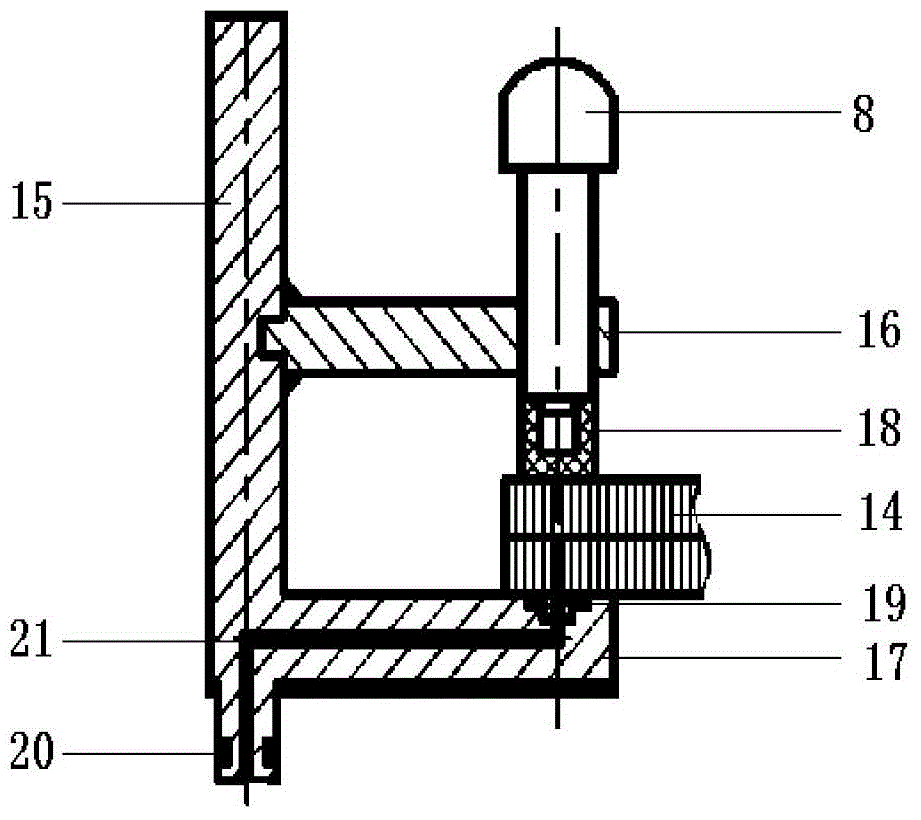

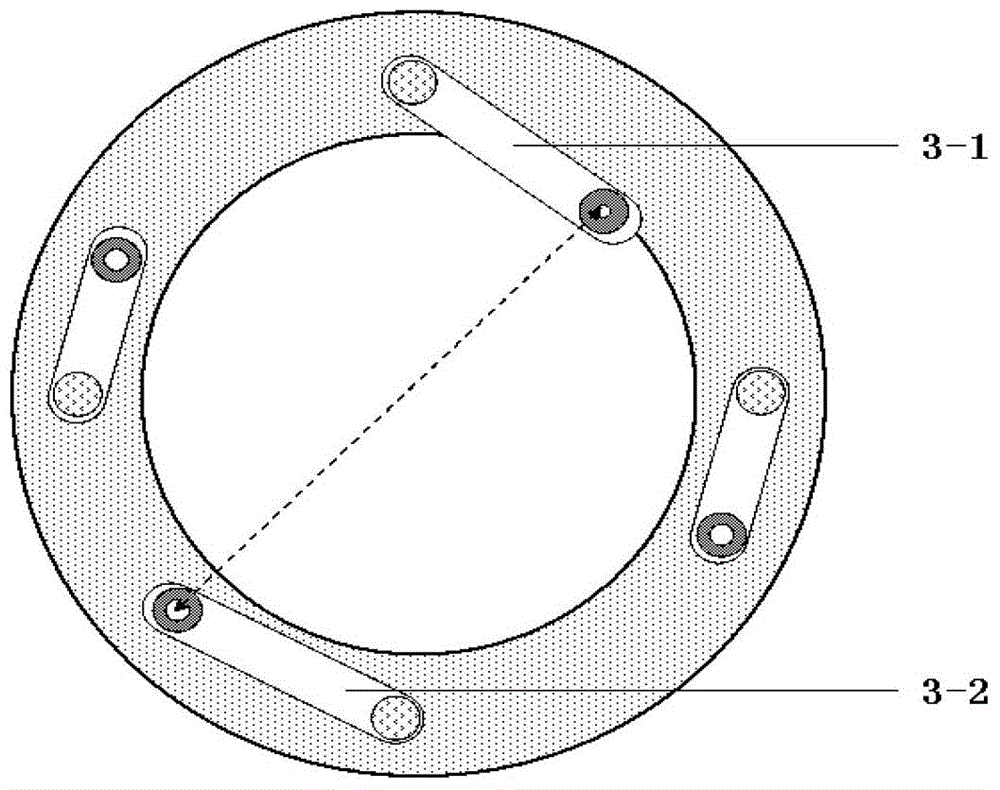

[0019] Example 1: see attached figure 1 . A variable-distance high-temperature and high-pressure visual core model clamping device mainly includes a model cabin upper cover 1, which is made of stainless steel and has an inverted cylindrical shape, an outer diameter of 325 mm and a height of 134 mm. There are two vertical sockets and a back pressure control hole on the top of the model cabin upper cover 1, and the distance between the two vertical sockets is 185 mm. The jack has a built-in ceramic electric heating rod 2 with a power of 100 watts. A temperature sensor jack and two mounting holes for hoisting bolts are also provided on the top of the upper cover 1 of the model cabin. Model cabin base 9, made of stainless steel, with an outer diameter of 325 mm and a height of 40 mm. The base 9 of the model cabin is provided with four sockets for installing the quick-connect variable-pitch model holder 3 and a hole for applying ring pressure. The model cabin upper cover 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com