Marine light-weight water-lubricated sealing device

A sealing device and water-lubricated technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of high mass of the shaft sleeve and its additional equipment, which have not been found in the literature and are rare, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

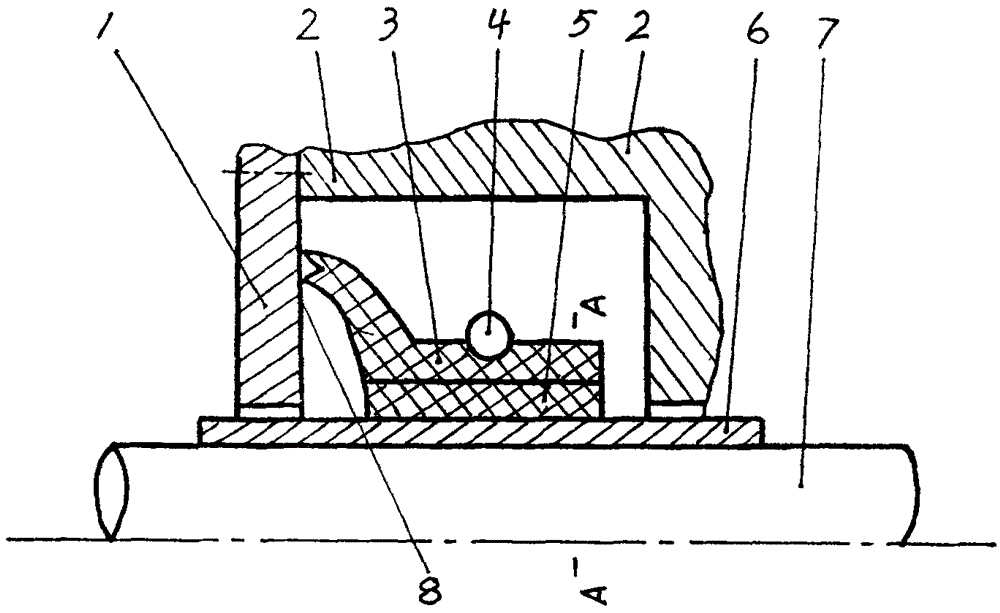

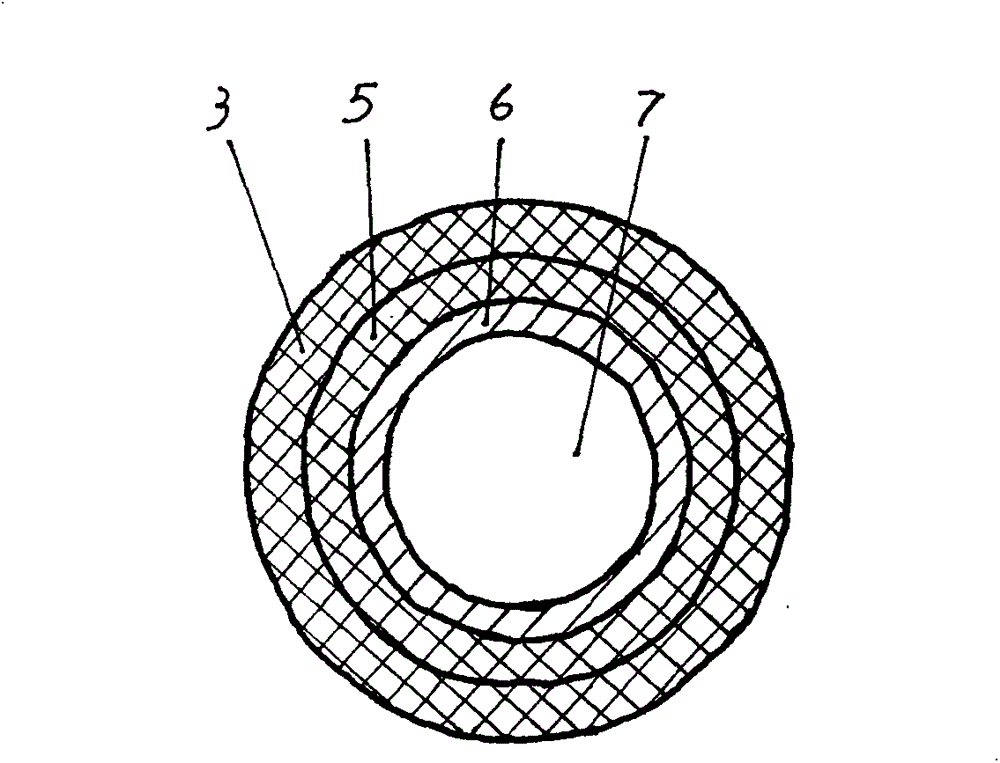

[0013] figure 1 , figure 2 Among them, the marine lightweight water-lubricated sealing device consists of a water-lubricated sealing seat 2 that surrounds the rotating shaft 7 and is fixedly installed on the hull, a sealing end cover 1 that surrounds the rotating shaft 7 and is fixedly installed on the water-lubricated sealing seat 2, and water-lubricated The sealing ring 3 is formed, the sealing end cover 1 is processed with a static sealing end face 8 perpendicular to the rotating shaft 7, the water-lubricating sealing ring 3 is placed inside the space surrounded by the water-lubricating sealing seat 2 and the sealing end cover 1, and fixed Installed and embraced on the sheath 6 wrapped on the outer surface of the rotating shaft 7, the sheath 6 is made of seawater corrosion-resistant copper material, the water-lubricated sealing ring 3 rotates synchronously with the rotating shaft 7, and the static sealing end face 8 and the water-lubricated sealing The ring 3 constitutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com