Resin asphalt ultraviolet aging testing equipment and testing method thereof

A technology of resin asphalt and aging test, which is applied to the preparation of test samples and the use of stable bending force to test the strength of materials, etc. It can solve the problems of inability to perform resin asphalt aging test, and achieve simple structure, high test accuracy and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

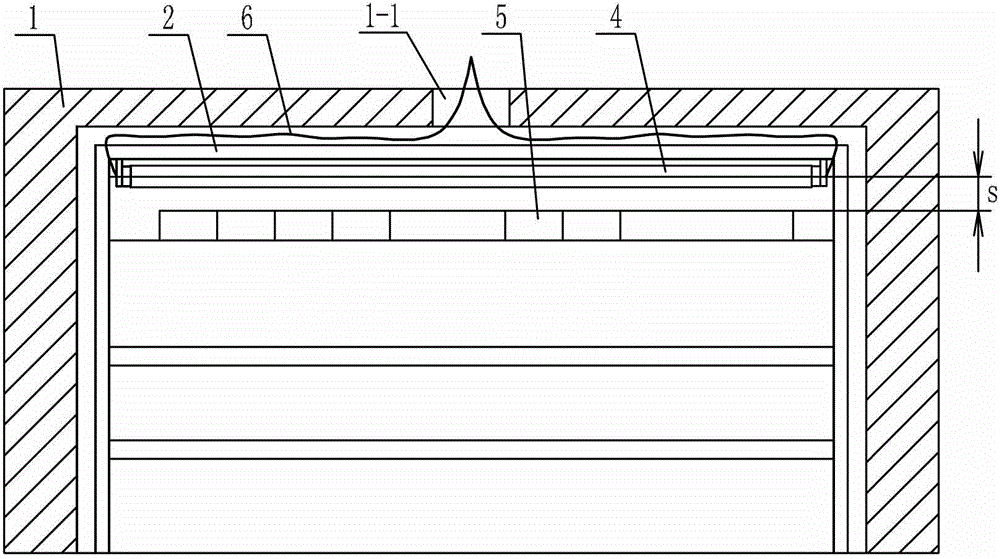

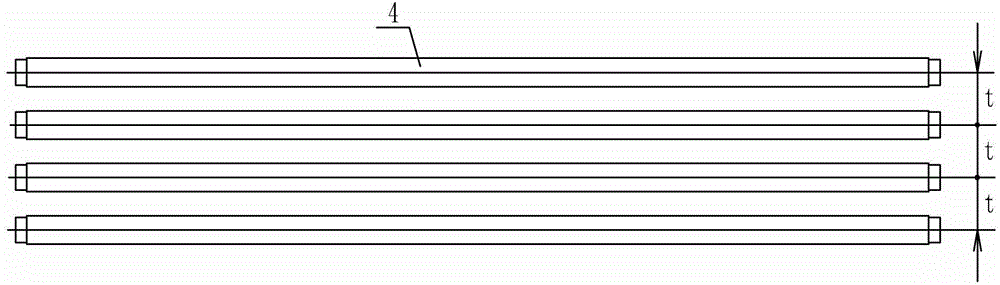

[0019] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment comprises ultraviolet aging incubator 1, lamp frame 2 and four ultraviolet lamp tubes 4, the front of ultraviolet aging incubator 1 is the box door 1-2 that opens in opposite directions, the top of ultraviolet aging incubator 1 Ventilation holes 1-1 are provided for connecting the lamp tube wire 6 with an external power supply. The lamp frame 2 is set in the ultraviolet aging incubator 1, and four ultraviolet lamp tubes 4 are horizontally fixed on the top of the lamp frame 2, two adjacent The distance t between the ultraviolet lamp tubes 4 is 65 mm to 75 mm. Four ultraviolet lamp tubes 4 are arranged in parallel through wires, and each ultraviolet lamp tube 4 has its matching ballast 5 and wires 6 . The ultraviolet lamp 4 adopts a UVA-340 lamp, its ultraviolet wavelength is 290-400nm, its power is 40W, and its ultraviolet irradiance is 40.62W / m2.

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 2 The present embodiment will be described. The pitch t of the ultraviolet lamp tubes 4 in the present embodiment is 70 mm. Other connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

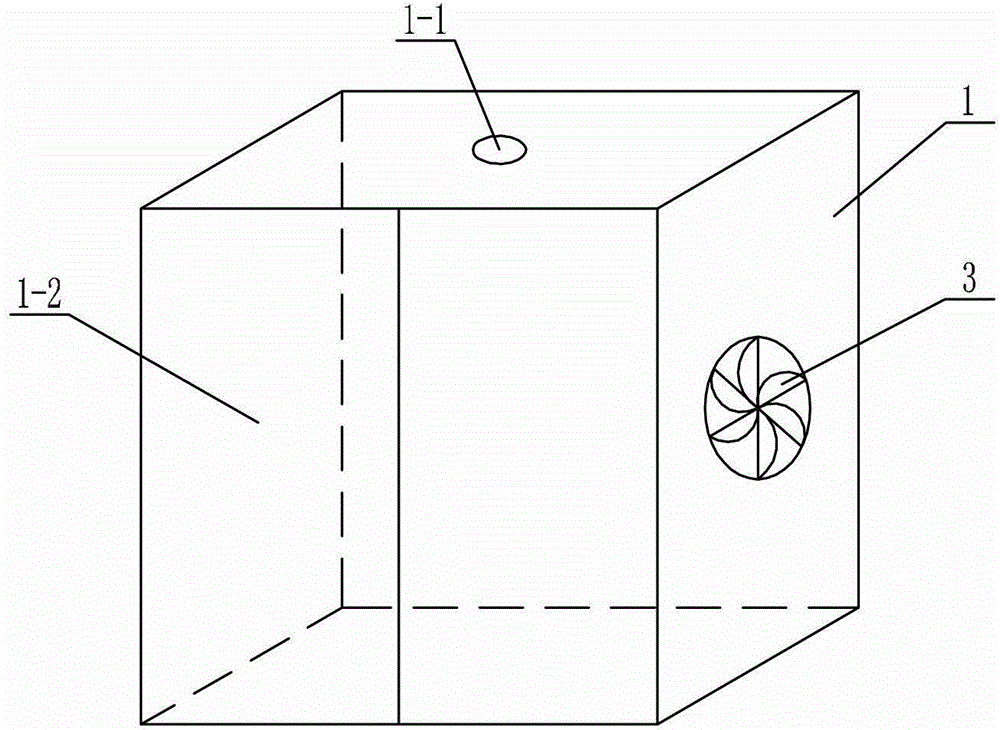

[0021] Specific implementation mode three: combination image 3 This embodiment is described. The difference between this embodiment and the third embodiment is that it also has an exhaust fan 3 installed on the side wall of the ultraviolet aging thermostat 1 . Exhaust fan 3 is used for air exchange inside and outside the box to ensure the temperature and humidity balance in the box. Other connections are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com