Method for producing hydrocarbon oil

A production method and technology for hydrocarbon oil, which are applied in the field of production of hydrocarbon oil, can solve the problems of reduced hydrocracking efficiency of wax fraction and failure to perform hydrocracking, and achieve the effects of suppressing deterioration over time and prolonging continuous use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084]

[0085] Containing 3.0% by mass of USY zeolite (silica / alumina molar ratio: 37) in powder form with an average particle diameter of 0.4 μm, powdered alumina boria (mass ratio of alumina / boria oxide: 5.6) A composition of 57.0% by mass and 40.0% by mass of powdered alumina is extruded into a cylindrical shape with a diameter of about 1.5mm and a length of about 3mm by a common method, and the obtained molded body is baked at 500°C in air for 1 hour, Get the carrier. After the support was impregnated with an aqueous solution of dichlorotetraammine platinum (II) in an amount of 0.8% by mass based on the mass of the support, the platinum atoms were dried at 120° C. for 3 hours, and then calcined at 500° C. 1 hour, and roasted in air to obtain a hydrocracking catalyst.

[0086]

[0087] Synthetic oil (FT synthetic oil) produced by the FT synthesis reaction was fractionated in a rectification column with a cut point of 360° C., and the obtained residual oil was used as ...

Embodiment 2

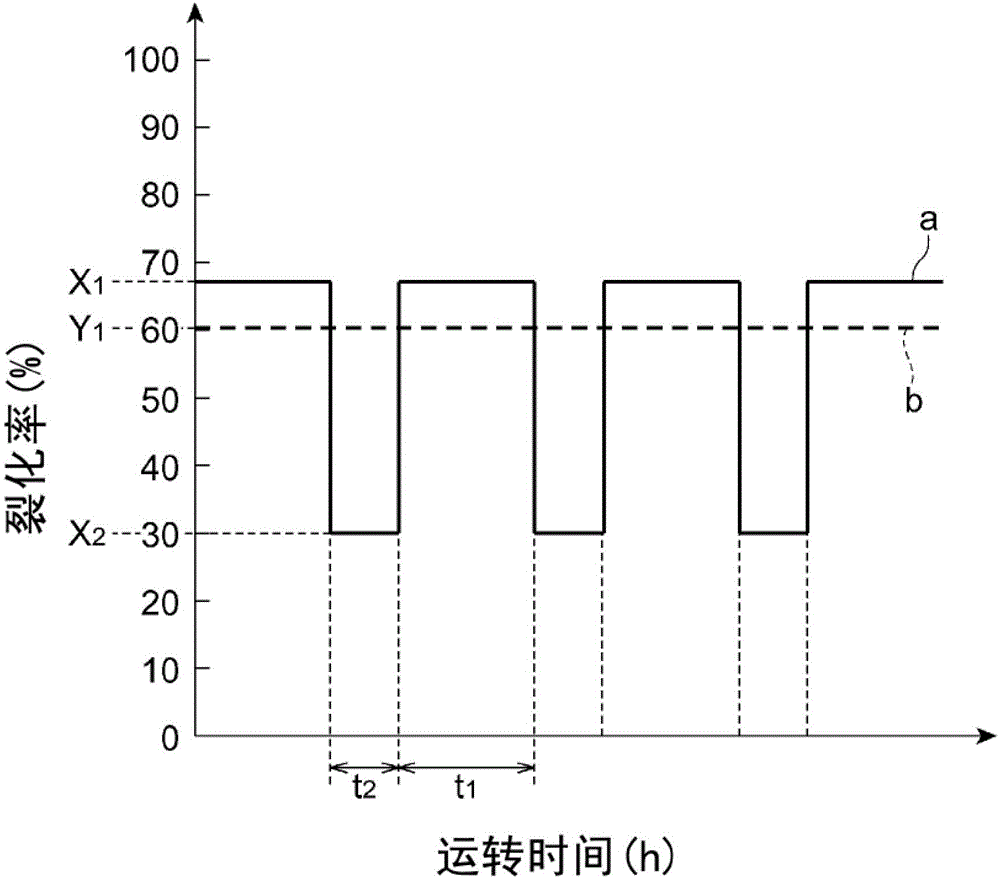

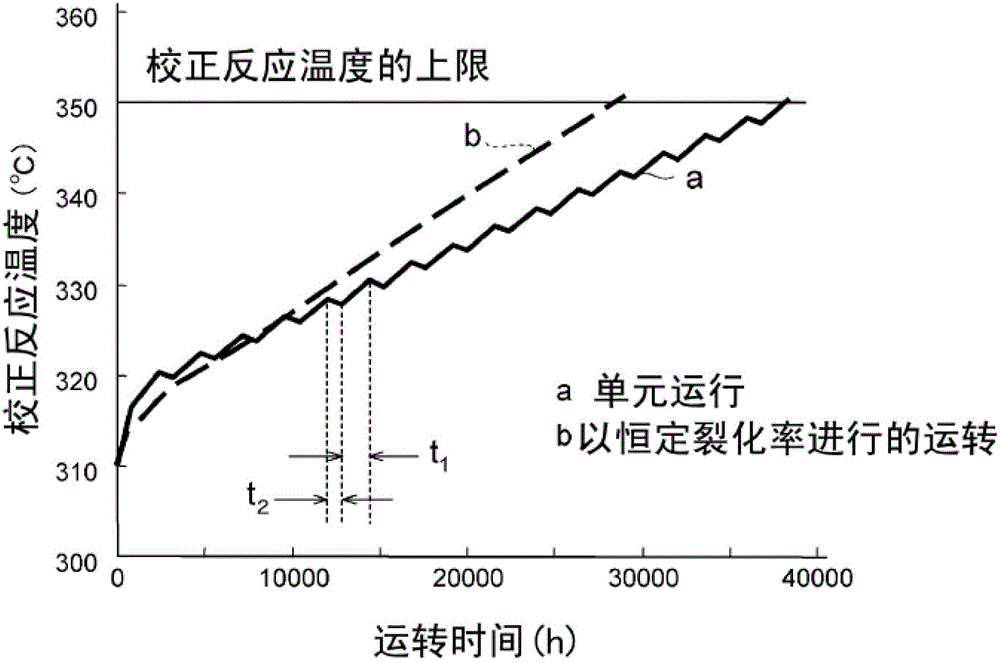

[0105] Using the same reactor, hydrocracking catalyst and FT wax fraction as in Example 1, by the same steps as in Example 1, operating conditions recorded in Table 2, the utilization of high cracking rate (78%) / low cracking rate ( 20%) for hydrocracking of unit operations. In the initial high cracking rate hydrocracking run, the corrected reaction temperature for a cracking rate of 78% at the start of the run was 314°C. In addition, the corrected reaction temperature for making the cracking rate 20% at the start of the operation of the hydrocracking operation at the first low cracking rate is 309°C. The yield of middle distillates was 75% over the whole period.

[0106] The time from the start of the operation until the calibration reaction temperature reached 350° C. which was set as the upper limit was 40,000 hours. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com