Straw tedder

A tumbler and straw technology, which is applied to hay spreaders, agricultural machinery and implements, applications, etc., can solve the problems of wasting resources, polluting the environment, ignoring the recycling of straws, etc., achieving convenient installation and operation, good use effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

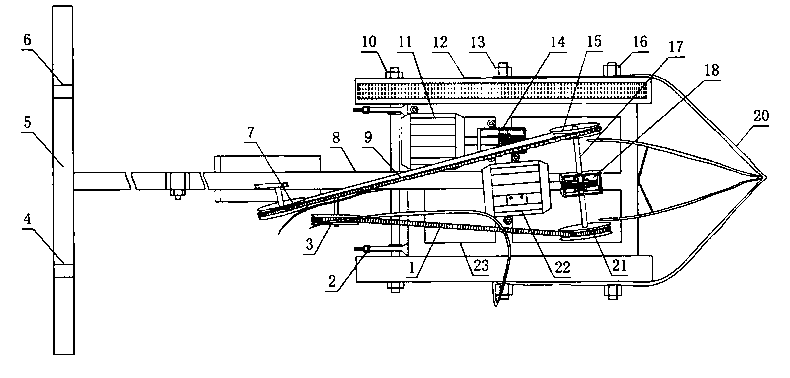

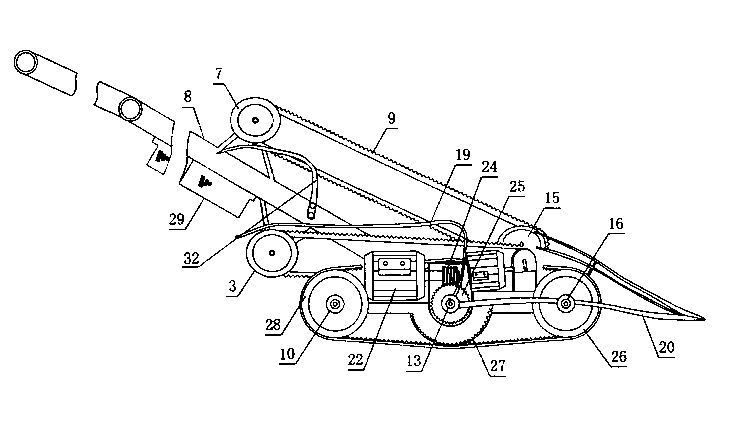

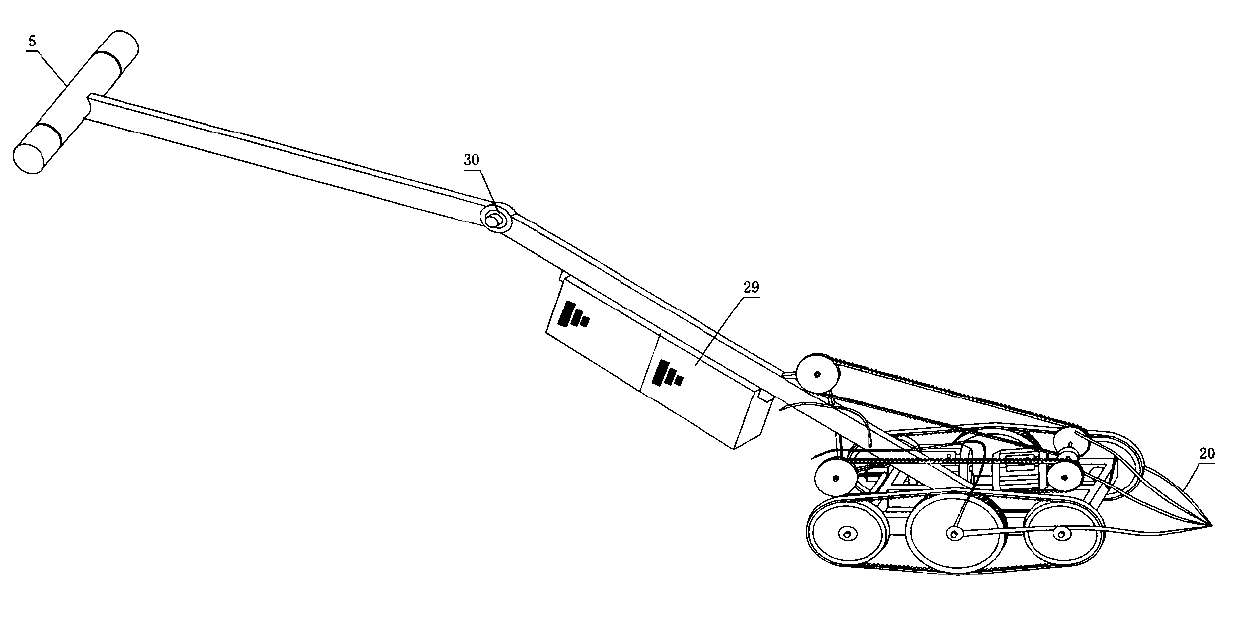

[0013] Figure 1-3 The front end of the chassis 23 shown in the figure is provided with a front axle 16, the middle part of the chassis is provided with a drive shaft 13, the rear end of the chassis is provided with a rear axle 10, and the left and right sides of the front axle are provided with front crawler wheels 26. The left and right sides of axle are provided with track drive wheel 27, the left and right sides of rear axle are provided with rear track wheel 28, track wheel 12 is respectively housed on the track wheel of left and right sides, are provided with drive tooth on the circumference of track drive wheel, track track There is a corresponding driving groove on the inner side. The left rear side of the underframe is provided with a walking drive motor 11, and the front end of the walking drive motor is provided with a worm gear box 14, and a worm screw 24 is arranged in the worm gear box, and the middle part of the drive shaft is provided with a worm wheel 25, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com