Fire-fighting monitor with in-parallel two-freedom-degree type slewing mechanisms

A technology of slewing mechanism and degree of freedom, which is applied in fire rescue and other fields, and can solve problems such as low rigidity, affecting the motion performance and response speed of fire monitors, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

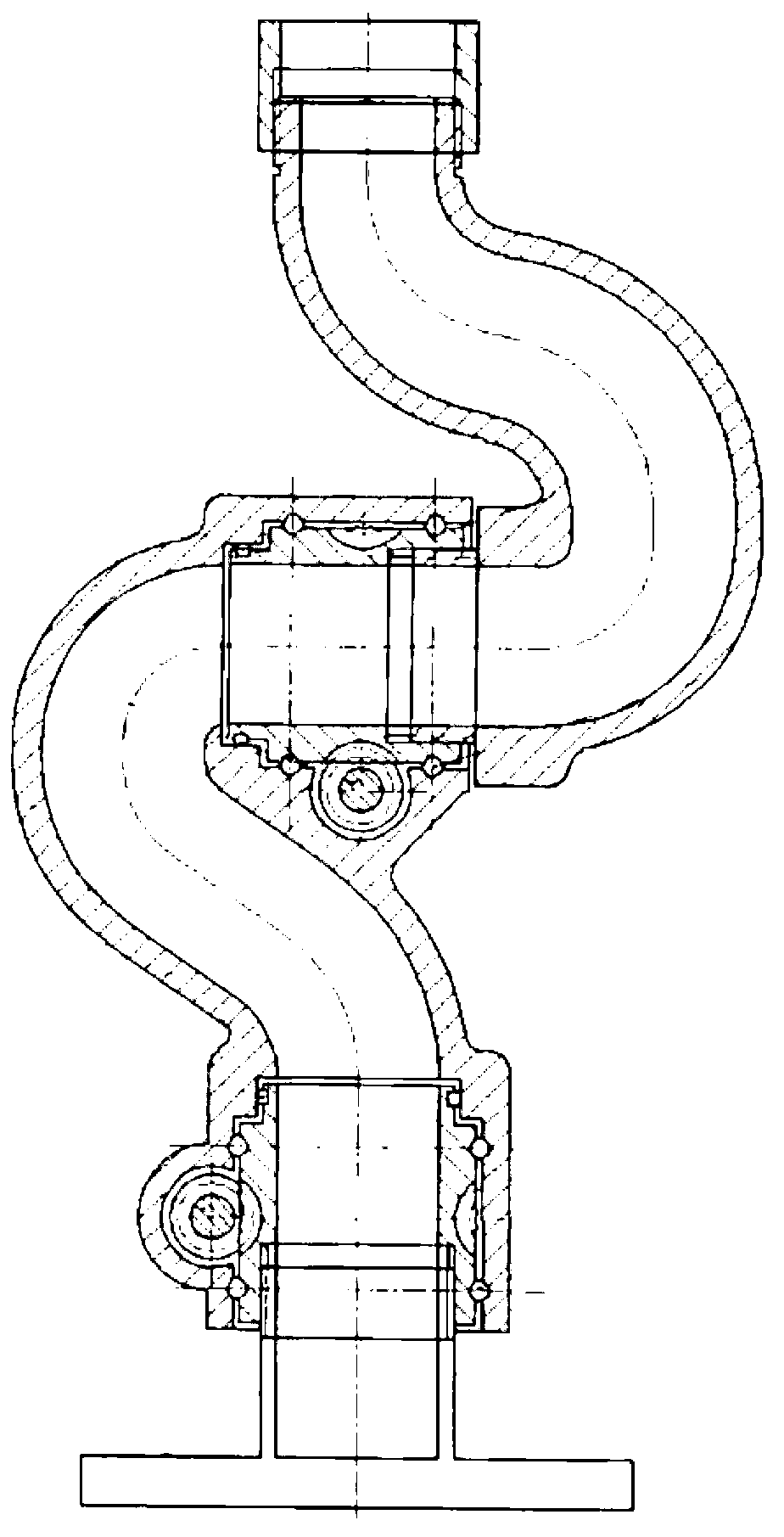

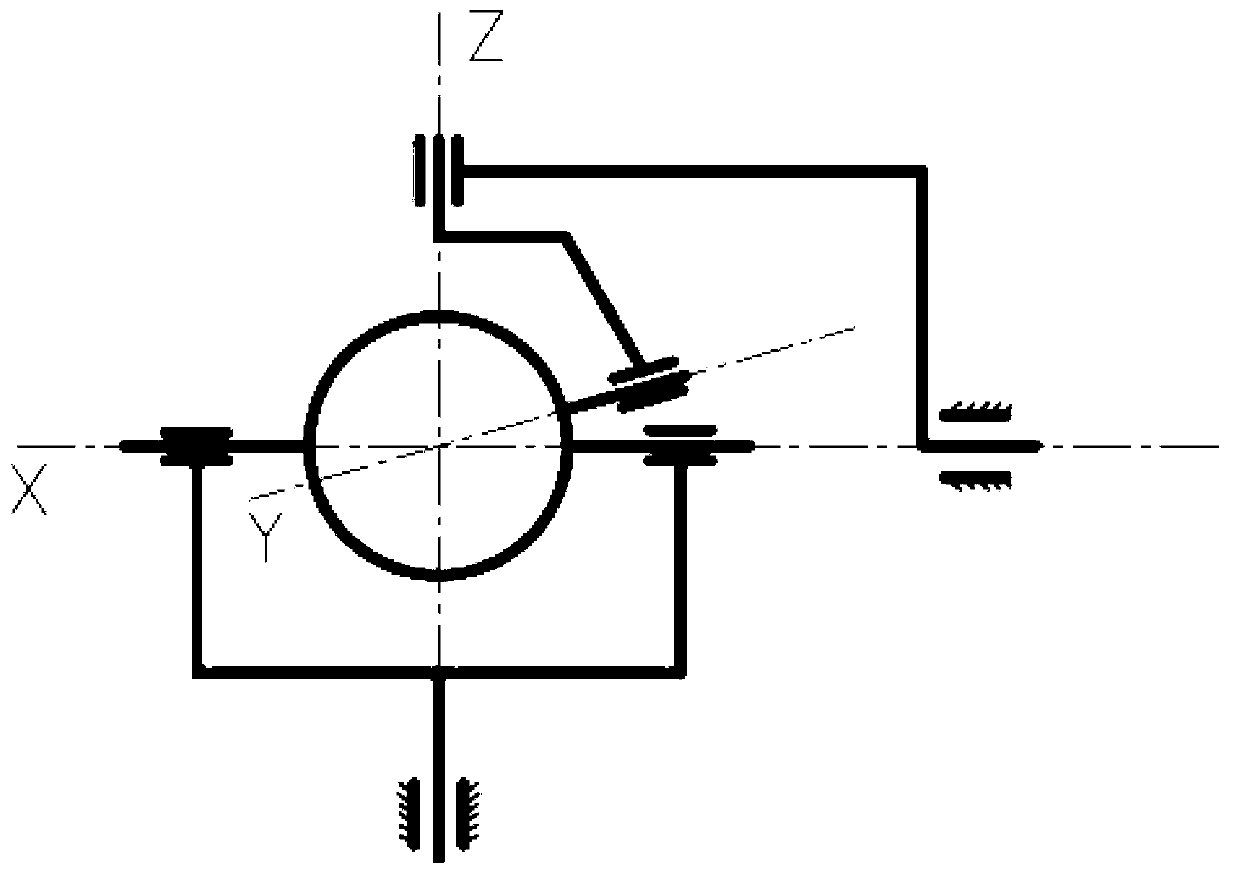

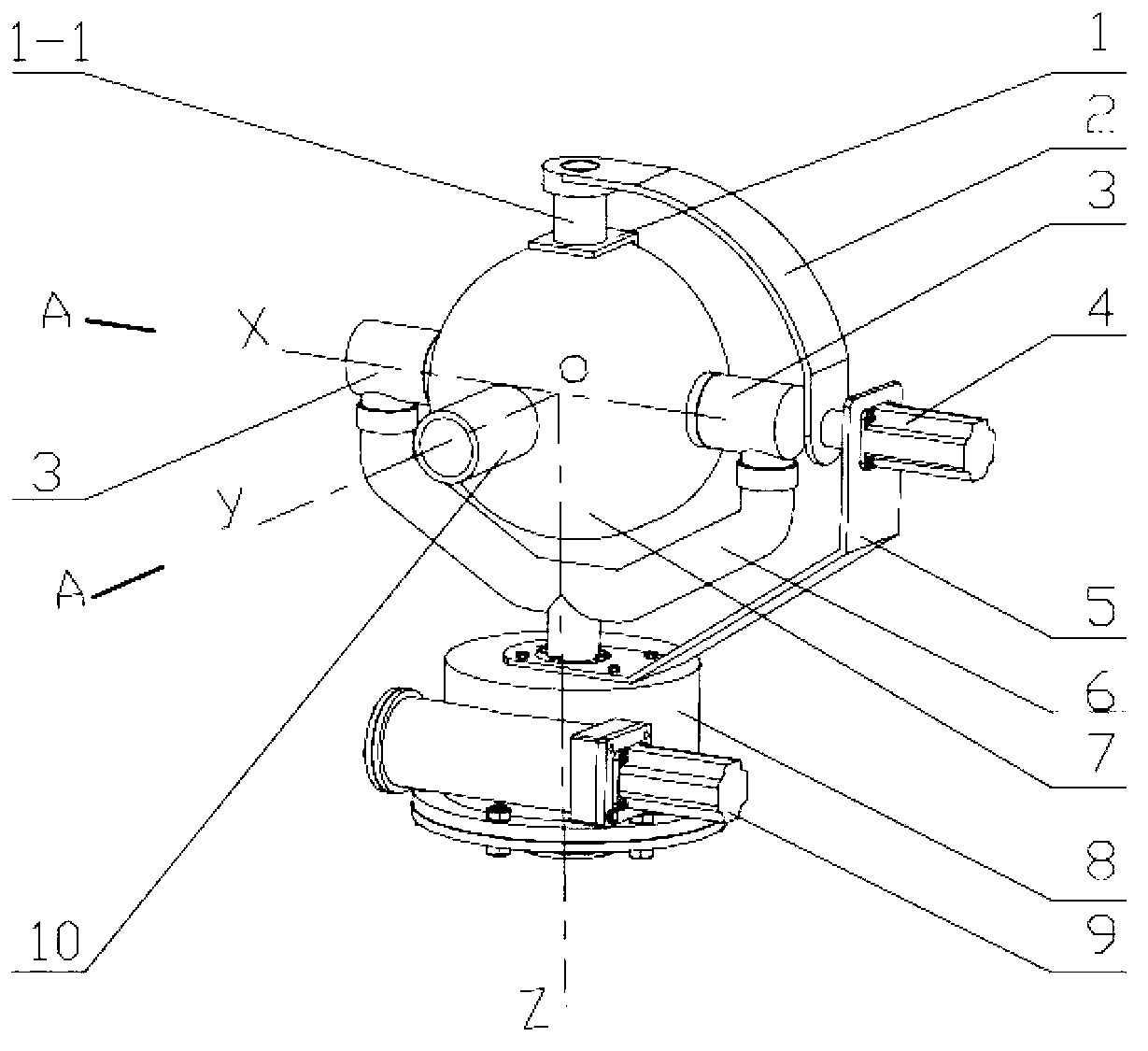

[0028] The fire monitor of the present embodiment is as image 3 , Figure 4 , Figure 5 As shown, it includes a gun body 7, a support 8, a gun body horizontal rotation drive mechanism and a gun body pitch rotation drive mechanism. Described gun body is hemispherical hollow body, and its spherical surface is provided with gun barrel 10, is provided with a section of hinge shaft 11 on the plane opposite to spherical surface, and the both sides of gun body 7 are respectively provided with a liquid inlet 12, two inlets. The center line of the liquid port is on a straight line and perpendicularly intersects with the center line of the hinge shaft, the center line of the gun barrel is defined as Y, and the center line of the two liquid inlets 12 is defined as X. The gun body horizontal rotation drive mechanism includes a second servo motor 9, a worm 13, a worm wheel 14 and a third connecting rod 6, the third connecting rod is a Y-shaped hollow rod, and the two symmetrical struts ...

Embodiment 2

[0030] In this embodiment, the rotary mechanism is a parallel two-degree-of-freedom fire monitor such as Figure 8 , Figure 9 , Figure 10 As shown, it includes a gun body 7, a support 8, a gun body horizontal rotation drive mechanism and a gun body pitch rotation drive mechanism. Described gun body is conical shape, and one end face is provided with gun barrel 10, is provided with a section of liquid inlet pipe 18 with the other end face, and the arc surface of gun body 7 both sides is respectively provided with a section connecting shaft 17, two connecting The center line of the shaft is on a straight line and perpendicular to the center line of the liquid inlet pipe 18. The center line of the gun barrel is defined as Y, and the center line of the two connecting shafts 17 is defined as X. The gun body horizontal rotary drive mechanism includes a second servo motor 9 and a third connecting rod 6, the third connecting rod is a solid Y-shaped rod, and the two symmetrical str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com