Glass bottle colour spraying and decoration firing method

A technology for glass bottles and ovens, which is applied in the field of material processing, and can solve problems such as paint falling off and decals not sticking tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for spraying and decorating glass bottles, comprising:

[0017] Wash the glass bottle with water containing 2% hydrofluoric acid, and treat the outer surface of the glass bottle;

[0018] spraying paint on the outer surface of the glass bottle;

[0019] Baking the painted glass bottles in an oven at 150-190°C for the first time;

[0020] Cool down to 70-80°C;

[0021] Soak the flower paper to be pasted in warm water;

[0022] At room temperature, paste the soaked flower paper on the outer surface of the cooled glass bottle and let it dry naturally;

[0023] Put the glass bottle into an oven at 160-180° C. for the second baking to obtain a painted and baked glass bottle.

[0024] Washing the glass bottle with water containing 2% hydrofluoric acid by mass can improve the problem of poor tinting strength of the bottle, and the first baking of the glass bottle after spraying paint at 150-190 ° C can improve the tinting strength of the bottle and prevent the bot...

Embodiment 2

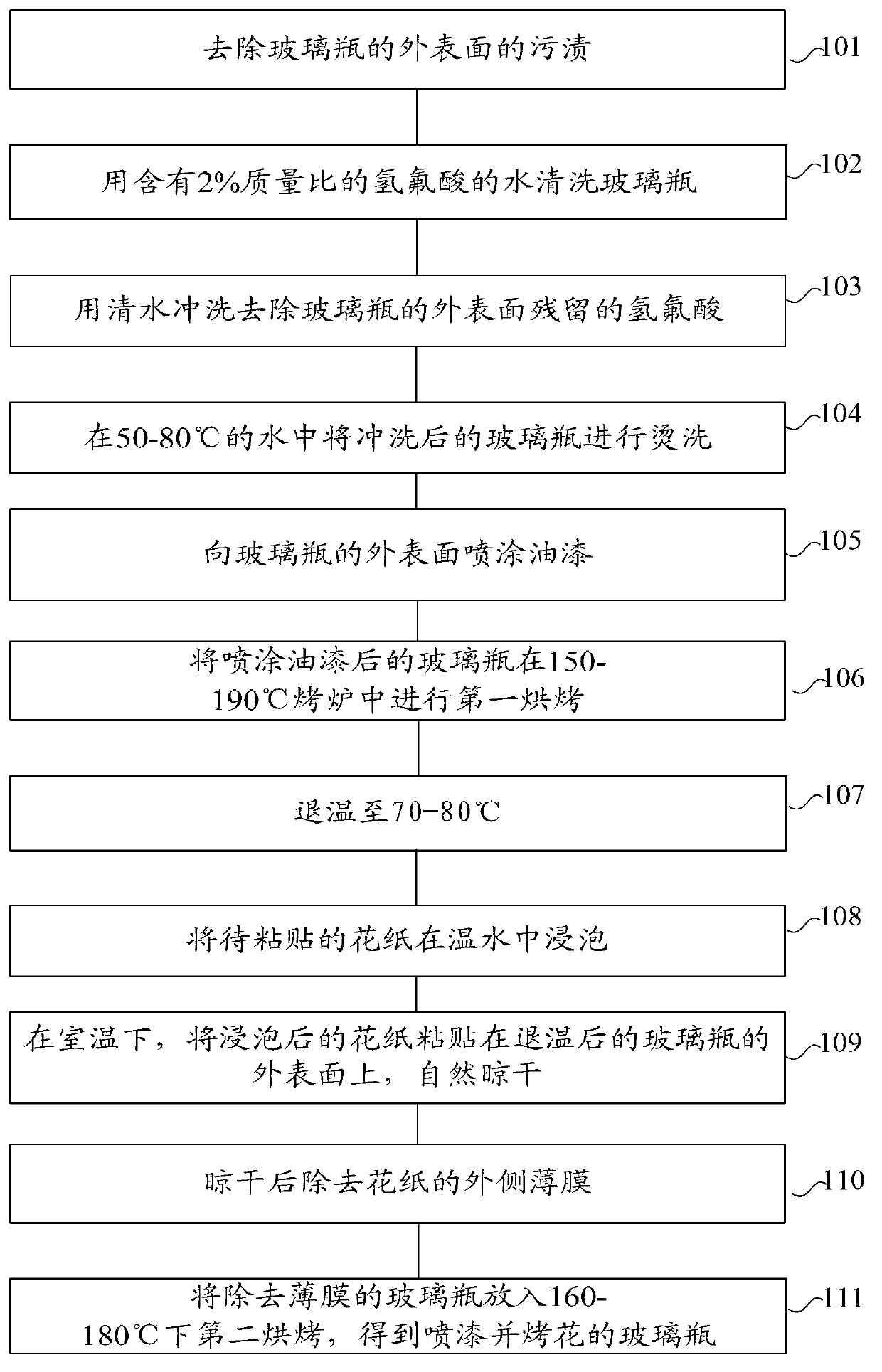

[0026] In the present embodiment, the flow process of glass bottle spray color decal method is, as figure 1 , as shown in:

[0027] Step 101, removing the stains on the outer surface of the glass bottle;

[0028] Removing stains can improve the adhesion between glass bottles and paint, and improve the uniformity of painting.

[0029] Usually, for the convenience of observation, the inner surface of the glass bottle should also be kept as clean as possible.

[0030] Step 102, clean the glass bottle with water containing 2% hydrofluoric acid by mass;

[0031] Hydrofluoric acid is a weak acid that can react with alkaline substances on the surface of the glass bottle and change the acidity and alkalinity of the surface of the glass bottle, thereby providing a prerequisite for stronger adhesion between the paint and the outer surface of the glass bottle during subsequent painting. Among them, 2% is a relatively strict control condition. At this mass percentage concentration, aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com