Cleaning device for graphite in ascension pipe of coke oven, and cleaning method by using same

A cleaning device and coke oven technology, applied in coke ovens, petroleum industry, furnace prevention/removal of fouling, etc., can solve the problems of heavy hammer not falling, cleaning, stuck and unable to rise pipes, etc., to improve temperature and high efficiency The effect of the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

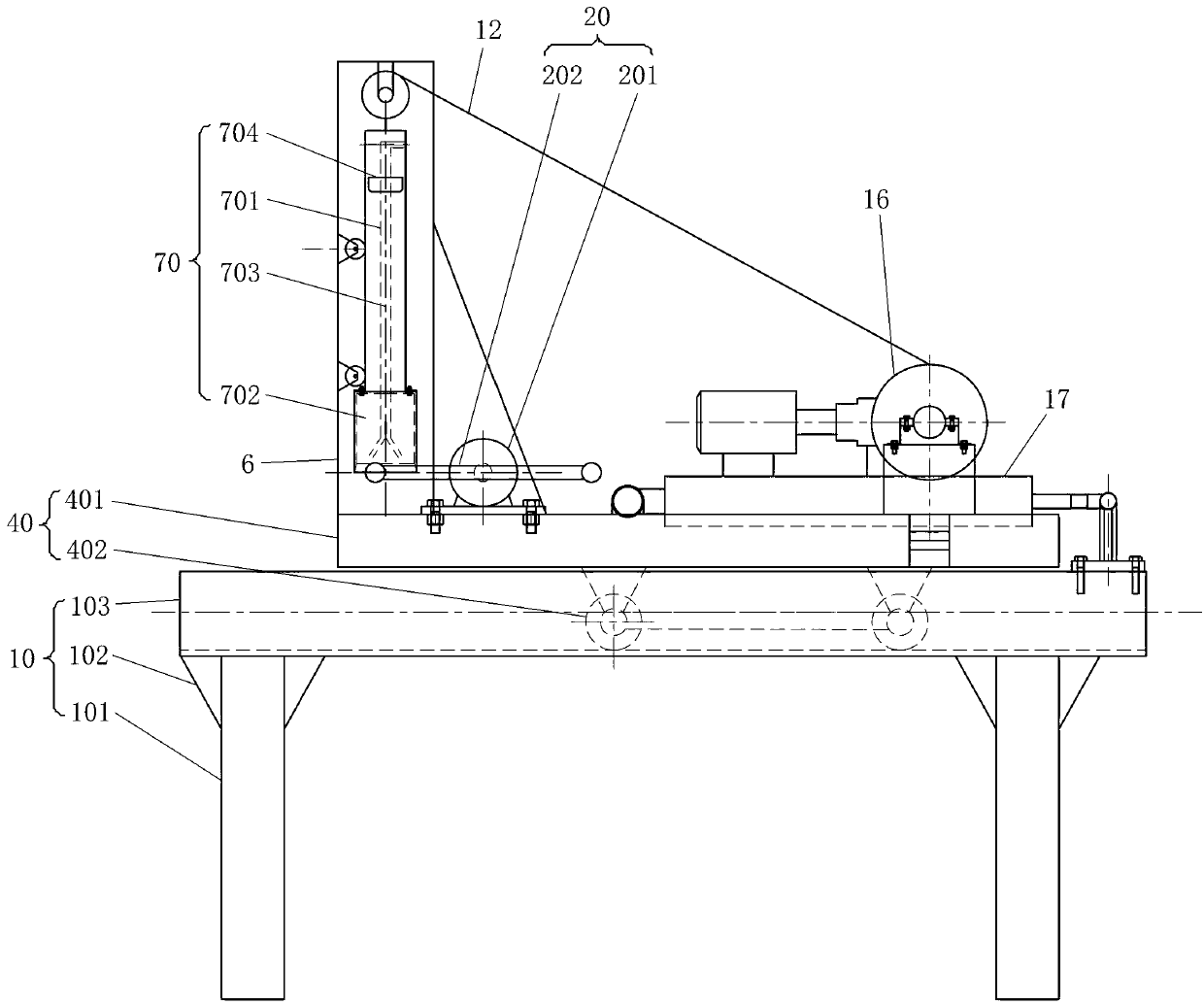

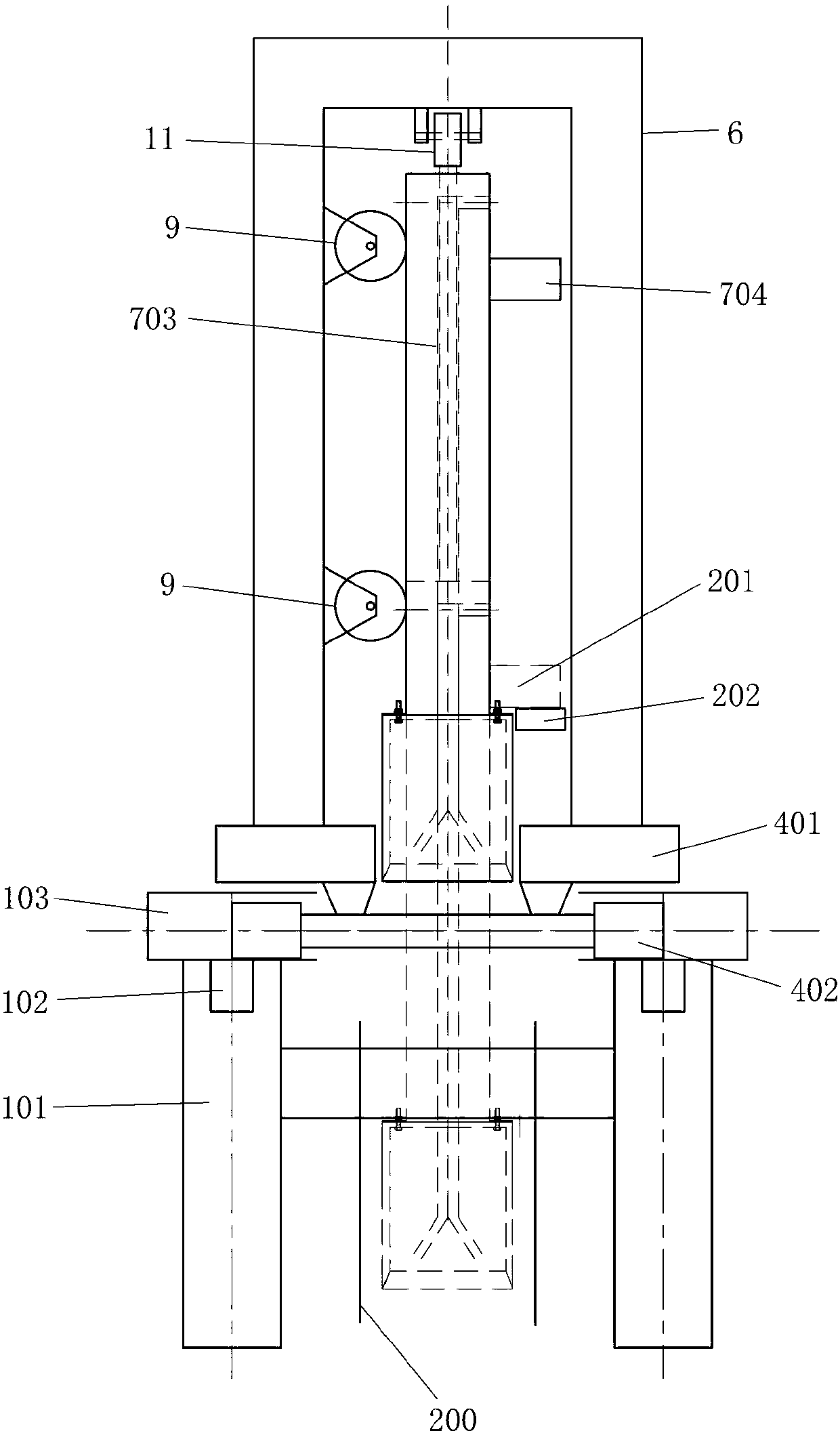

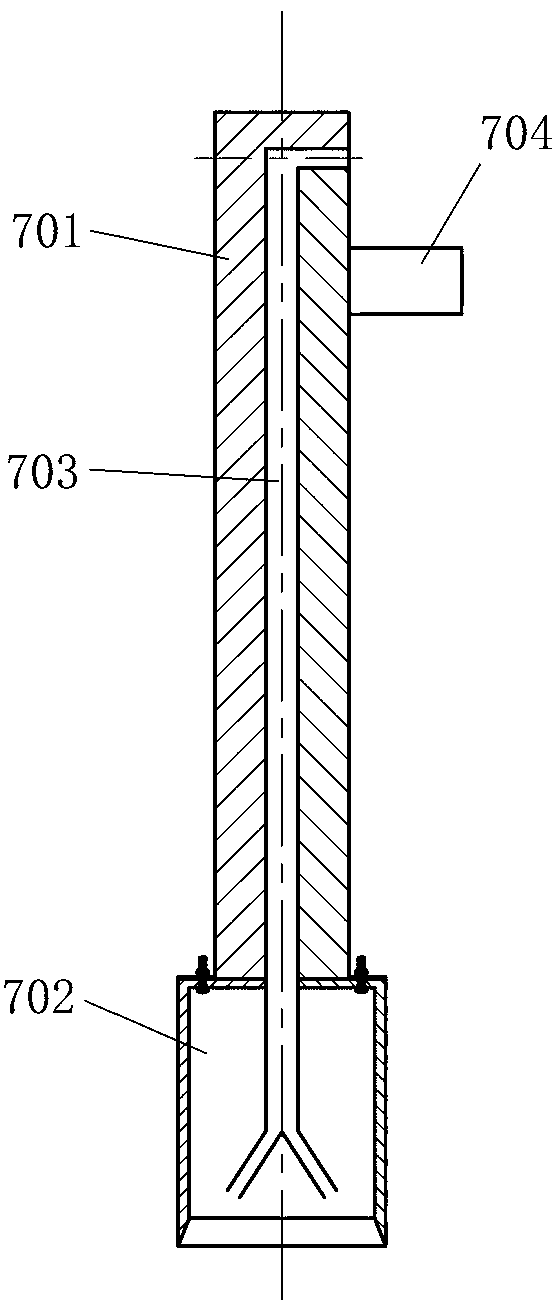

[0025] figure 1 is a front view of a riser graphite cleaning device according to an embodiment of the present invention. figure 2 It is a left view of the riser graphite cleaning device according to the embodiment of the present invention. image 3 It is a cross-sectional view of the pick hammer of the riser graphite cleaning device according to the embodiment of the present invention. Figure 4 It is a schematic diagram of the engagement of the horizontal iron and the rotating connecting rod in the riser pipe graphite cleaning device according to the embodiment of the present invention.

[0026] Such as Figure 1-3 As shown, the riser graphite cleaning device according to the embodiment of the present invention includes a mobile trolley 40, a mobile trolley support frame 10, a winch 16 arranged at the rear end of the mobile trolley 40, a driving device 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com