A sliding form system variable diameter assembled sliding form platform

A prefabricated, sliding-form technology, applied in the direction of formwork/template/work frame, large-capacity bulk material storage, on-site preparation of building components, etc. problems such as the length of small radiating beams, to achieve the effect of improving the reuse rate, reducing the construction cost and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

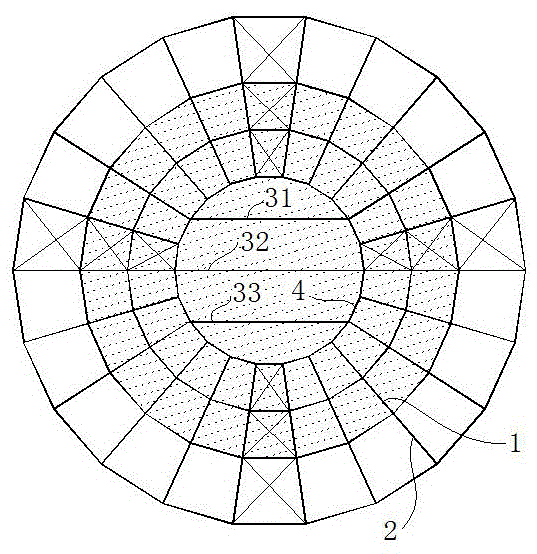

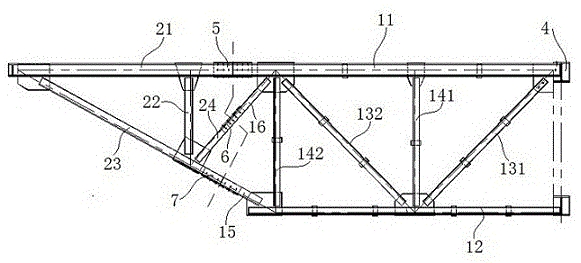

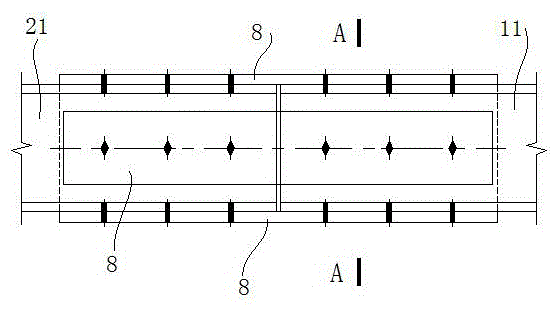

[0028] to combine figure 1 with figure 2 , a variable-diameter assembled sliding-form platform of a sliding form system in this embodiment includes a central steel ring assembly, a fixed-diameter radiant beam truss assembly 1 and a variable-diameter radiant beam truss assembly 2 . Such as figure 1As shown, the central steel ring assembly in this embodiment includes a first shaped steel beam 31, a second shaped steel beam 32, a third shaped steel beam 33 and a central steel ring truss 4, the central steel ring truss 4 is a circular structure, The center steel ring truss 4 is internally provided with a first steel beam 31, a second steel beam 32 and a third steel beam 33, and the first steel beam 31 and the third steel beam 33 are located on both sides of the second steel beam 32, And respectively set parallel to the second steel beam 32, the second steel beam 32 is located at the diameter position of the central steel ring truss 4, the first steel beam 31 and the third ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com