Annular workbench for split charging of pistons and connecting rods of engine

A technology of piston connecting rod and engine, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of low degree of automation, large floor space, high labor intensity of workers, etc., and achieve the effect of saving investment and small floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

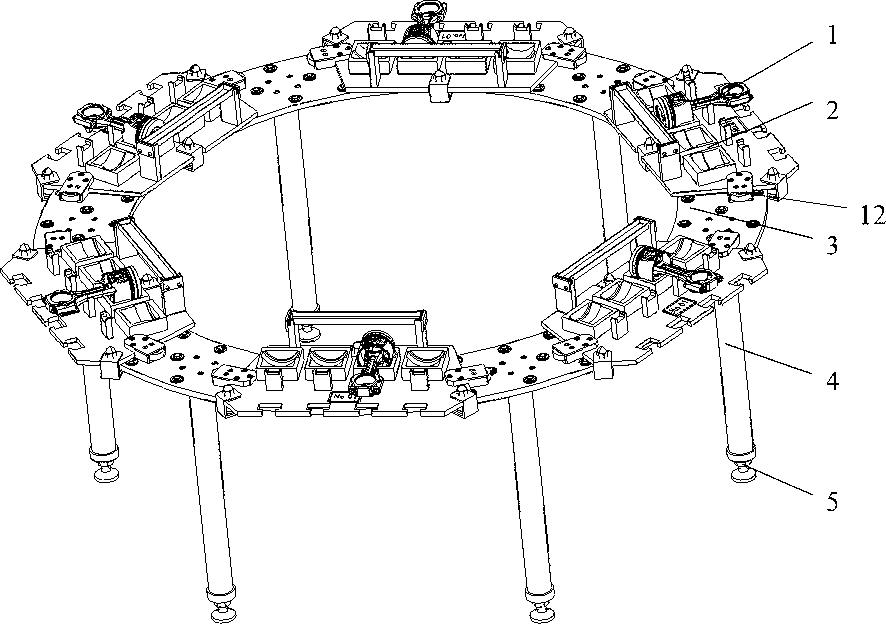

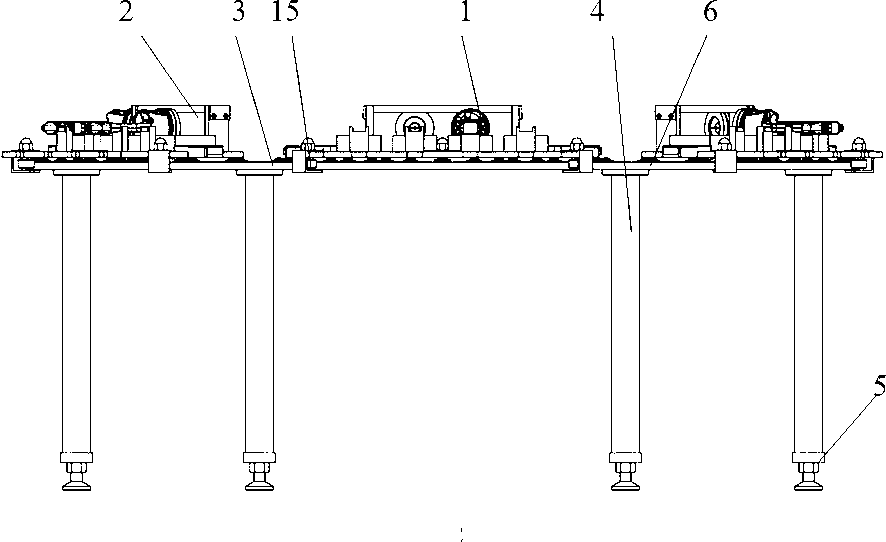

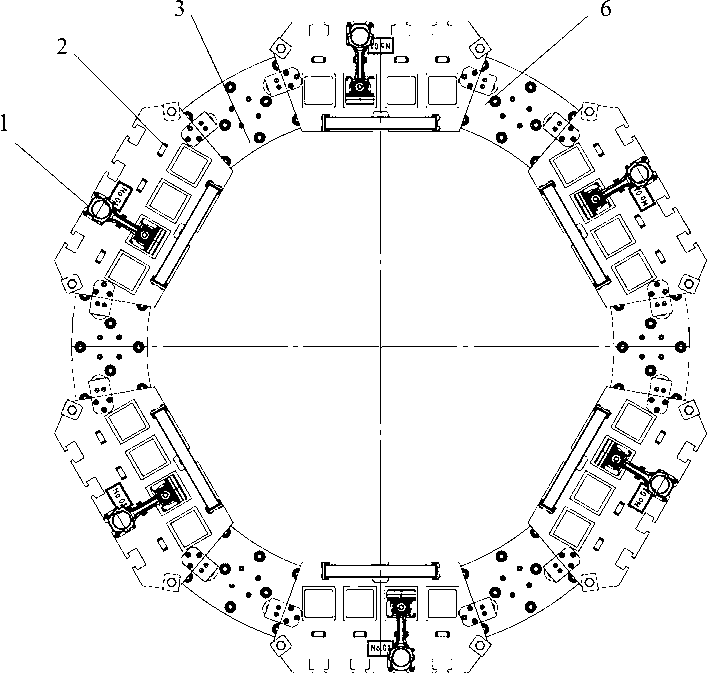

[0025] see figure 1 , figure 2 and image 3 , the annular workbench used for engine piston and connecting rod subassembly includes an annular turntable 3, and the effect of the annular turntable 3 is equivalent to a ring-shaped conveying guide rail. Universal balls 6 are evenly distributed on the turntable 3, and the turntable 3. Six struts 4 are fixedly installed on the bottom surface, and an anchor 5 is fixedly installed at the lower end of each strut 4. On the turntable 3, there are six piston connecting rod sub-packaging tray mechanisms 2, see Figure 4 and Figure 5 , through the universal ball 6 to make the piston connecting rod packing tray mechanism 2 slide and transport on the turntable 3 conveniently. Piston connecting rod packing tray mechanism 2 comprises tray base plate 7, four piston support blocks 9 are evenly distributed side by side on the tray base plate 7, piston support blocks 9 are box-shaped, and the bottom surface is a concave arc surface; The two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com