Platinum device for optical glass feed preparation

An optical glass, platinum technology, applied in glass furnace equipment, glass manufacturing equipment, glass production and other directions, can solve the problems of glass liquid being difficult to stir evenly, affecting glass uniformity, affecting glass yield rate, etc., to improve glass slag preparation capacity , Improve the glass yield and improve the effect of melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

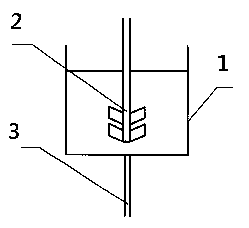

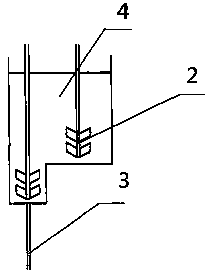

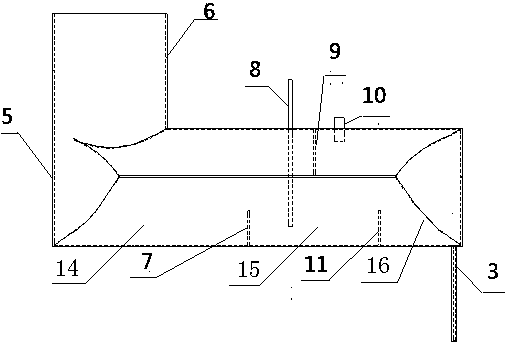

[0018] like image 3 As shown, the special-shaped crucible of the present invention adopts a boot-shaped crucible 5, and the cross-section of the boot-shaped crucible 5 is a semicircle sealed with an arc or a polygon sealed with an arc.

[0019] Wherein the polygonal cross section is a semicircle, rectangle or other shapes. The left dividing plate 7, the middle dividing plate 9, and the right dividing plate 11 divide the whole crucible into three parts: the melting chamber 14, the homogenizing chamber 15 and the discharge chamber 16, and the three parts are connected. When the raw material is continuously added into the melting chamber 14 from the feeding pipe 6, the molten glass flows into the discharging chamber 16 through the homogenizing chamber 15 curve after the raw material is melted, and continuously flows out from the discharging pipe 3. Due to the effect of the three partitions, the flow distance of the glass is lengthened, which is better than the traditional singl...

Embodiment 2

[0023] like Figure 4 As shown, the special-shaped crucible of the present invention adopts a trapezoidal crucible 12, and the cross section of the trapezoidal crucible 12 is trapezoidal, and its feeding pipe, left, right and middle partition plates, ventilation pipes, air vents and the arrangement of the feeding pipe are the same as in the embodiment 1.

Embodiment 3

[0025] like Figure 5 Shown, special-shaped crucible of the present invention adopts polygonal crucible 13, and the cross-section of polygonal crucible 13 is polygonal shape, and its feeding pipe, left, right and middle dividing plate, ventilation pipe, venting hole and the same implementation with discharging pipe arrangement mode example 1.

[0026] The part of the smelting device of the present invention in contact with molten glass is preferably made of pure platinum or zirconium-strengthened platinum material or platinum alloy.

[0027] Ventilation pipe 8 of the present invention can adopt multiple modes, as straight pipe, connect bubbler etc. under straight pipe.

[0028] Give two examples of producing optical glass with the device of the present invention below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com