Centrifugal fan set used for cooling high speed train traction motor

A technology for high-speed EMUs and traction motors, which can be applied to machines/engines, liquid fuel engines, components of pumping devices for elastic fluids, etc., and can solve problems such as low efficiency, heavy components, and insufficient boosting capacity. Achieve the effect of high efficiency, simple and compact structure, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

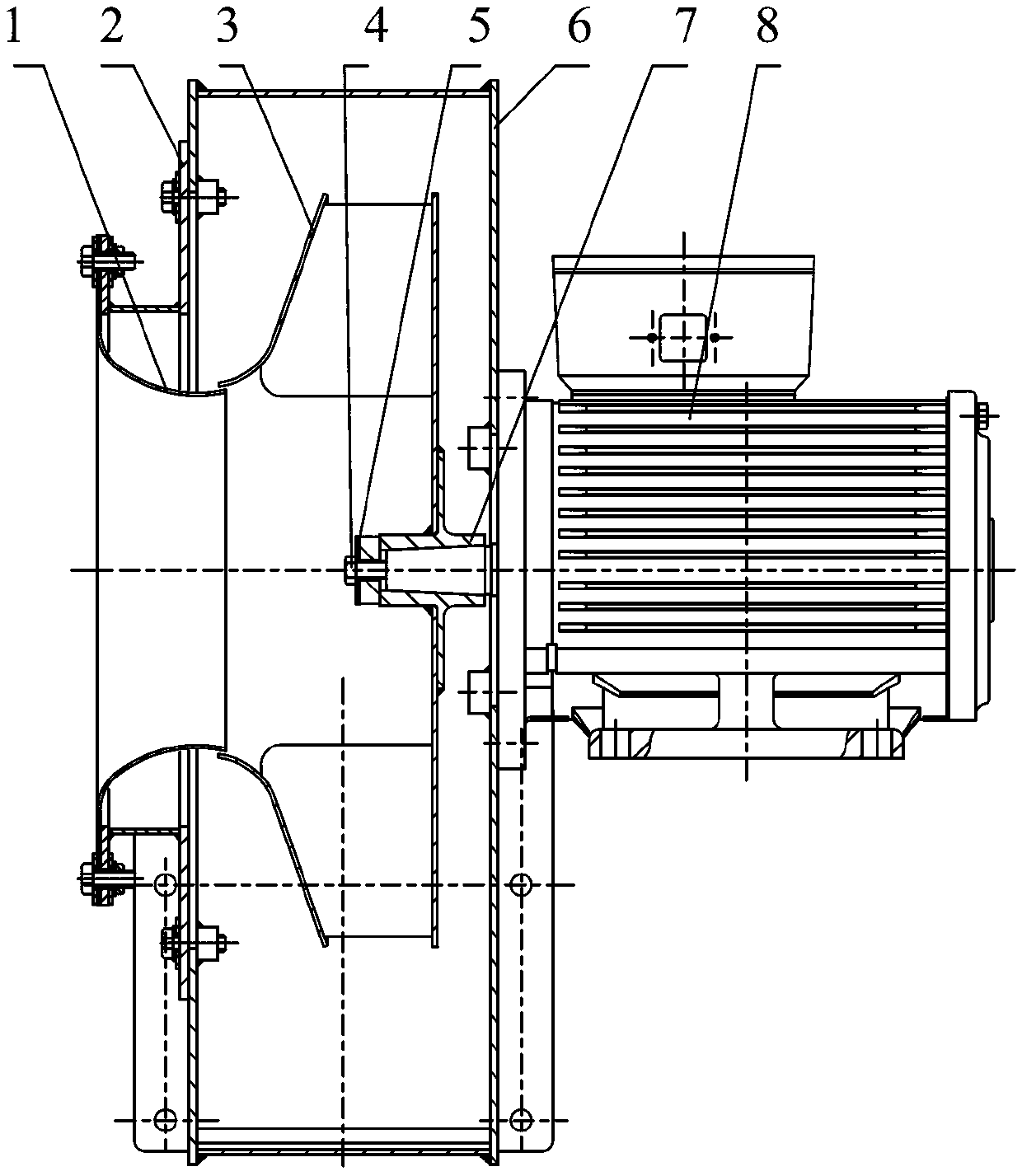

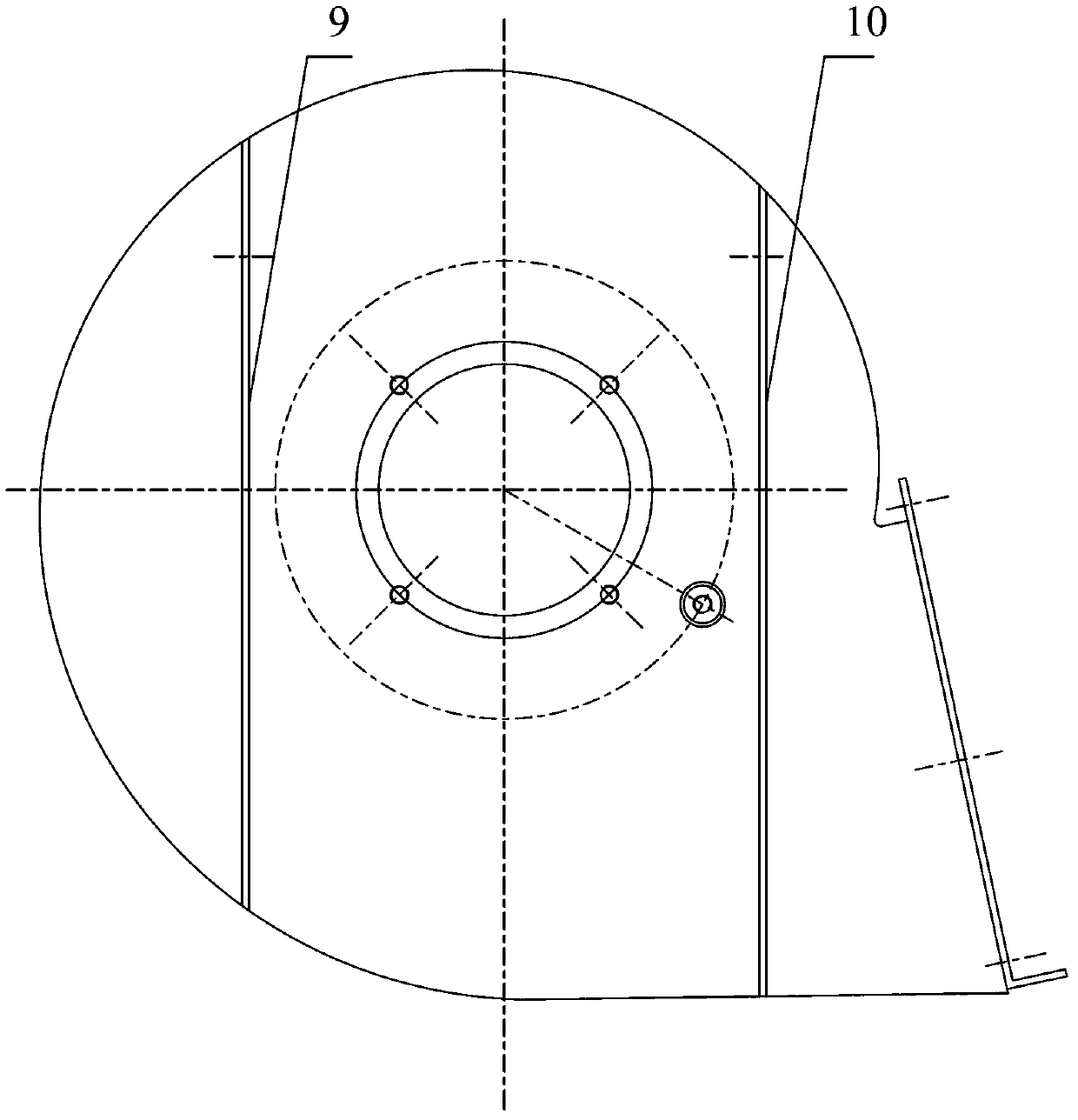

[0023] Such as figure 1 , figure 2 As shown, a centrifugal fan unit for cooling the traction motor of a high-speed EMU includes a collector 1, a flange 2, a fan impeller 3, a volute 6, a shaft disc 7 and a motor 8. The air intake channel of the collector 1 is a zoom-type air intake channel, and the air intake channel of the collector 1 is composed of a gas rapid acceleration section and a gas buffer section, and the gas rapid acceleration section and the gas buffer section are formed An arc-shaped transition structure, the gas buffer section is connected with the conical arc-shaped front disc of the fan impeller 3 in an arc transition, and the arc-axial ratio of the gas rapid acceleration section and the gas buffer section is 1 :8-1:5. There is a gap between the gas buffer section of the collector 1 and the fan impeller 3 , and the gap is 1%-3% of the inlet diameter of the tail end of the gas buffer section of the collector 1 . The fan impeller 3 is composed of a cone-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com