Loading machine unloading parameter testing device and method

A parameter testing and loader technology, applied in the field of machinery, can solve the problems of low measurement accuracy, inability to keep up with enterprises, low efficiency, etc., to achieve accurate measurement, avoid the influence of human factors, and avoid the effects of human factor interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

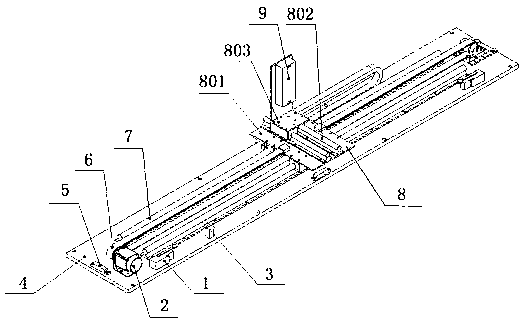

[0036] Such as figure 1 As shown, the loader unloading parameter test device includes a power source 2, a transmission system, a base plate 4, a longitudinal slide rail 7, a sliding table 8, and a distance measuring sensor 9; the power source 2 passes through the transmission system and the sliding table 8 connection, the sliding workbench 8 is installed on the longitudinal slide rail 7 through the slider, and can perform linear motion on the longitudinal slide rail 7 under the action of the power source 2 and the transmission system; the sliding workbench 8 includes The bracket 803 on it is vertically installed on the distance measuring sensor 9 on the bracket 803 .

[0037] The power source 2 is a stepping motor with an encoder, and the displacement of the workbench from the origin switch at this time can be accurately determined by the number of steps of the stepping motor recorded by the encoder.

[0038] The extension shaft of the power source 2 is equipped with a synchr...

Embodiment 2

[0045] Loader unloading parameter testing device The process of testing loader unloading parameters is as follows:

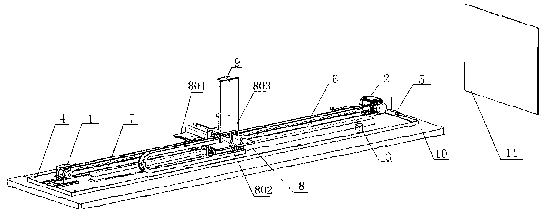

[0046]A. The loader unloading parameter testing device is placed horizontally on the test table 10. A reference plane 11 is installed on the horizontal foundation at one end of the loader unloading parameter testing device near the origin switch 3. The longitudinal direction of the loader unloading parameter testing device is in phase with the reference plane 11. Vertical, the distance from the origin switch 3 of the loader unloading parameter test device to the reference plane 11 is a definite value;

[0047] B. Park the two wheels of the front axle of the wheel loader or the front end of the crawler loader frame at a position tangent to the reference plane 11, and at the same time, the bucket edge is located in the testable area of the loader unloading parameter test device, and lift the loader Move the arm to the highest point, and keep the unloading angle ...

Embodiment 3

[0056] Loader unloading parameter testing device The process of testing loader unloading parameters is as follows:

[0057] A. The loader unloading parameter testing device is placed horizontally on the test table 10. A reference plane 11 is installed on the horizontal foundation at one end of the loader unloading parameter testing device near the origin switch 3. The longitudinal direction of the loader unloading parameter testing device is in phase with the reference plane 11. Vertical, the distance from the origin switch 3 of the loader unloading parameter test device to the reference plane 11 is a definite value;

[0058] B. Park the two wheels of the front axle of the wheel loader or the front end of the crawler loader frame at a position tangent to the reference plane 11, and at the same time, the bucket edge is located in the testable area of the loader unloading parameter test device, and lift the loader Move the arm to the highest point, and keep the unloading angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com