Method for identifying aging degree of silicon rubber composite insulator

A technology of composite insulators and aging degree, which is applied in the field of analysis and detection, to achieve the effects of high precision, wide range of analysis samples, and accurate quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

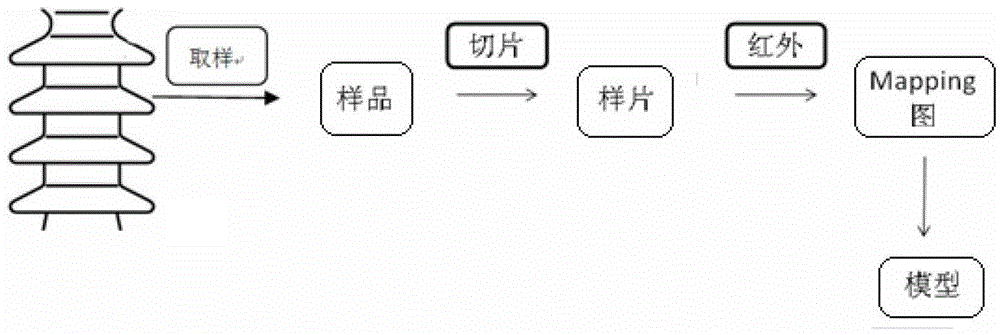

[0032] In this embodiment, the silicone rubber sheet made in the laboratory is used as the object, and after it is subjected to an accelerated ultraviolet aging test, this method is used to identify its aging degree, (for the flow chart, see figure 1 ), specifically including the following steps:

[0033] (1) A batch of silicone rubber is refined in the laboratory, and an aging experiment is carried out for a period of time in a UV accelerated aging box;

[0034] (2) Sampling and sectioning every 240 hours; when slicing, the sample is frozen by an electric cooling table, and the thickness of the sample is 10-20 μm; the darker the color, the thinner the thickness. Mark one side of the aged surface for easy analysis;

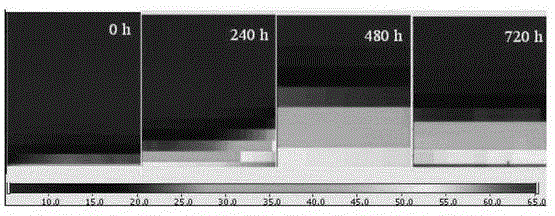

[0035] (3) Silicon methyl 1296cm -1 In order to calibrate the peak, the sample is scanned by micro-infrared, and the micro-infrared Mapping diagram of the 0h, 240h, 480h, 720h sample is obtained, see figure 2 ; Among them, the test conditions are: reflective m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com