Method and apparatus for orienting measuring instrument

A technology of measuring device and orienting device, applied in the direction of measuring device, test/calibration device, test/calibration of volume measurement, etc., which can solve the problem of no inspection and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

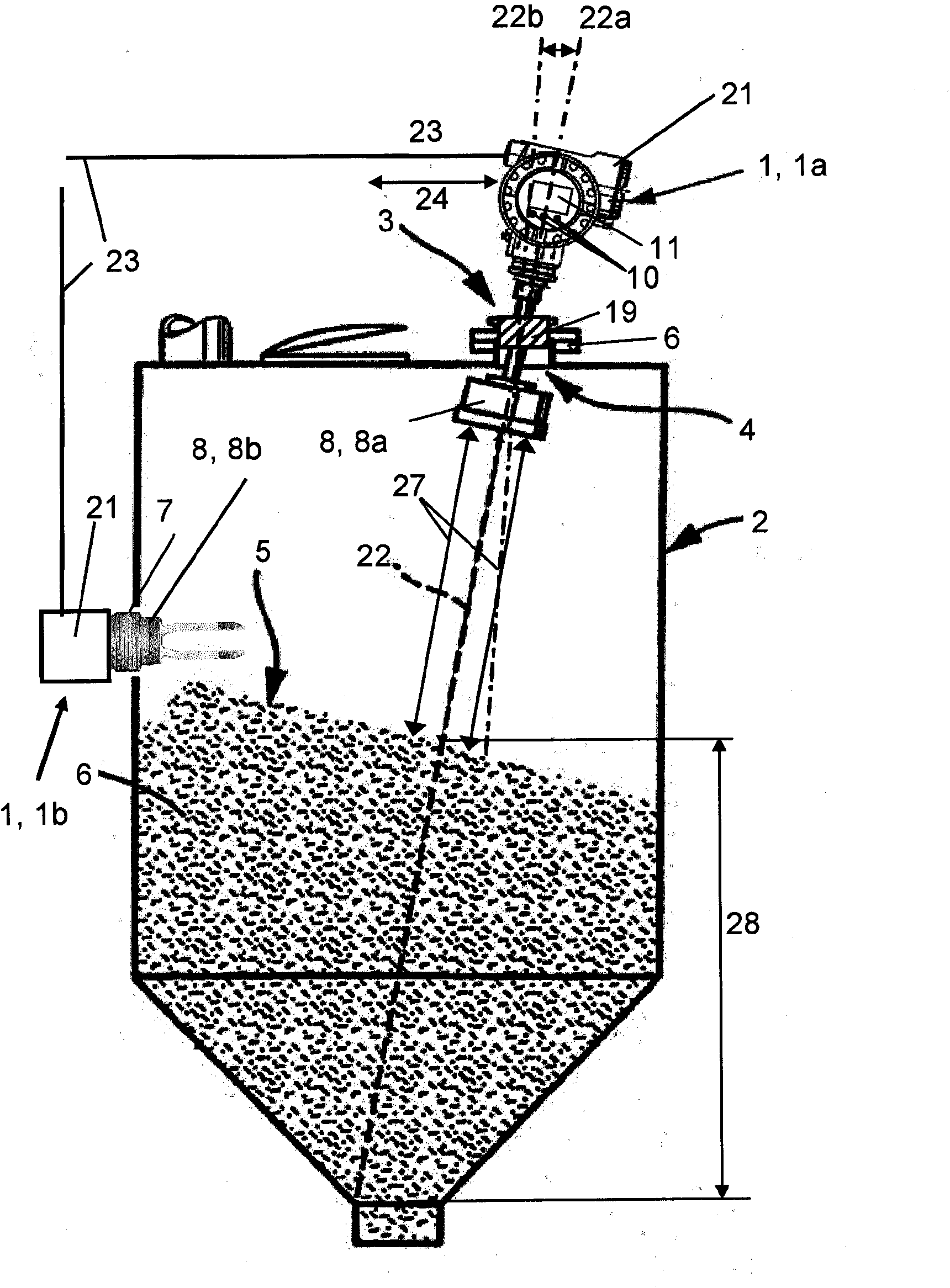

[0023] figure 1 Shown is a measuring device 1 a installed in a spout 4 on a container 2 , which uses the transit time measurement method to determine a level 21 of a medium 5 or filling substance 5 in the container 2 .

[0024] In most applications the measuring device 1 , 1 a is fastened via a flange 6 in the nozzle 4 on the container 2 . However, it is also possible to fix the measuring device 1 in the container 2 by screwing into the threaded opening 7 . figure 1 An option for mechanical orientation of the sensor unit 8 by means of a mechanical orientation device 3 is shown, such as a compression and a gas-tight ball joint. However, also other orientation devices 3 , such as, for example, rotating or swiveling wedges, flange assemblies, etc., can be used as the orientation device 3 .

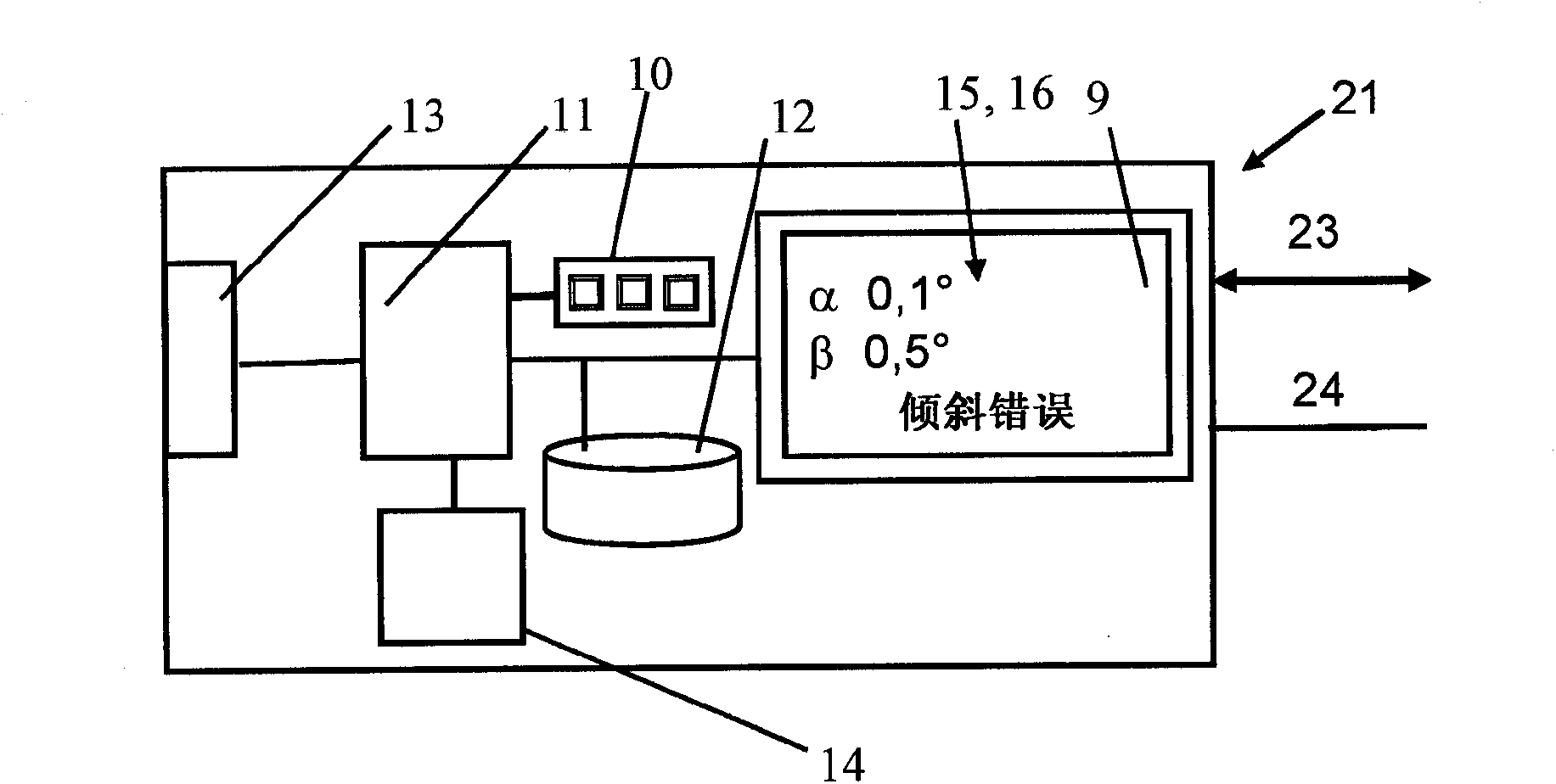

[0025] figure 1 A measuring device 1 is shown which essentially consists of a sensor unit 8 located in a container 2 and a measuring transmitter unit 21 located in a housing outside the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com